You might always receive a request from customer for a 12Х18Н10Т material,What is 12Х18Н10Т?What is the ASTM equivalent grade of 12Х18Н10Т?Is it the same as AISI 321 ?In this page,you would find the explantation of 12Х18Н10Т

12Х18Н10Т,old Х18Н10Т is a Stainless steel grade under GOST standard GOST 5632,It is the equivalent grade as AISI 321,Which is an austenitic stainless steel alloyed with titanium (Ti) to stabilize carbon and prevent chromium-carbide precipitation.12Х18Н10Т can be worked in 425-9000C high temperature conditions.

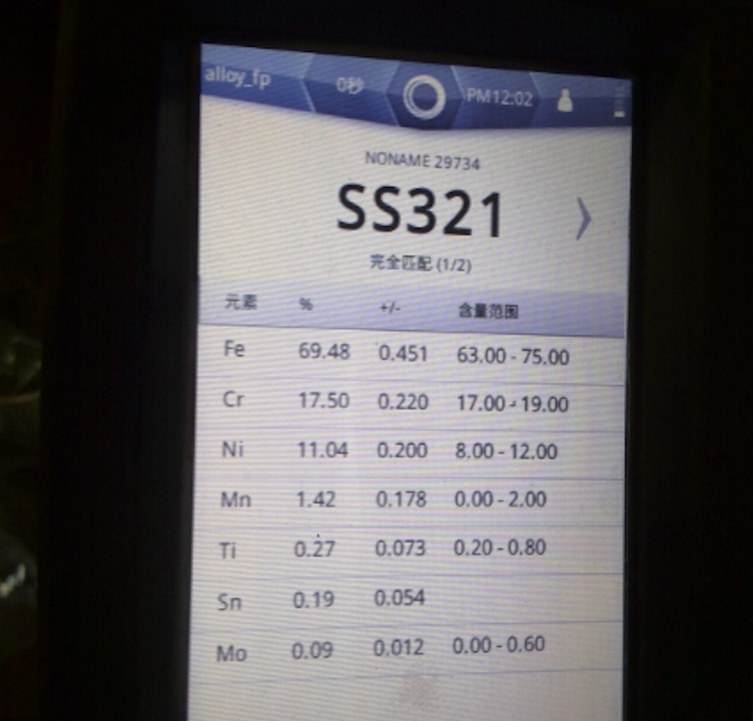

Chemical Composition of 12Х18Н10Т

| C | Si | Mn | Ni | S | P | Cr | Cu | – |

| up to 0.12 | up to 0.8 | up to 2 | 9 – 11 | up to 0.02 | up to 0.035 | 17 – 19 | up to 0.3 | (5 C – 0.8) Ti, the rest is Fe |

percentage of chromium (17% – 19%) determines its ability to passivate and increases its anti – corrosion properties.

The addition of nickel (9% – 11%) classifies this steel as austenitic. Thanks to this, steel grade 12Х18Н10Т is characterized by an excellent combination of the technological qualities of stainless steels and outstanding operational properties.

The effect of carbon in the alloy (0.1%) provides an austenitic structure of the steel (at temperatures above 900 °C).

Mechanical properties material 12X18N10T

| Assortment | Size | For example. | s in | s T | d 5 | y | KCU | Thermal processing |

| – | mm | – | MPa | MPa | % | % | kJ/ m2 | – |

| Cold-formed pipes, GOST 9941-81 | 549 | 35 | ||||||

| Hot-deformed pipes, GOST 9940-81 | 529 | 40 | ||||||

| Rod, GOST 5949-75 | up to Ø 60 | 510 | 196 | 40 | 55 | Hardening 1020 – 1100 o C, Air cooling, | ||

| Wire, GOST 18143-72 | 540-830 | 20-25 | ||||||

| Forgings, GOST 25054-81 | up to 1000 | 510 | 196 | 35-38 | 40-52 | Hardening 1050 – 1100 o C, water, | ||

| Thick sheet, GOST 7350-77 | 530 | 235 | 38 | Quenching 1000 – 1080 o C, Cooling water, | ||||

| Thin sheet, GOST 5582-75 | 530 | 205 | 40 | Quenching 1050 – 1080 o C, Cooling water, | ||||

| Thin sheet hard-worked, GOST 5582-75 | 880-1080 | 10 | ||||||

| Thin semi-hardened sheet, GOST 5582-75 | 740 | 25 |

About AISI 321

Grade 321 stainless steel (1.4541) is a heat resistant grade supplied into numerous industry sectors. The key property of this grade is the added titanium content (5 x C%) stabilising the material and making its resistance to carbide precipitation when exposed to high temperatures and resistance to oxidation its main characteristics

AISI 321 is a titanium stabilised chromium-nickel austenitic stainless steel with good strength and excellent corrosion resistance, as supplied in the annealed condition with a typical brinell hardness of 175.

Chemical Composition of AISI 321

| C | Si | Mn | P | S | Cr | Ni | Ti |

| % | ≤ % | ≤ % | ≤ % | ≤ % | % | % | ≤ % |

| ≤ 0.08 | 1 | 2 | 0.045 | 0.015 | 17.0-19.0 | 9.00-12.0 | 5xC |

Mechanical Property of AISI 321

| Hardness | 0.2% Yield strength Rp | Tensile strength Rm | Elongation A5 | Modulus of elasticity |

| ≤ HB | ≥ N/mm² | N/mm² | ≥ % | kN/mm² |

| 215 | 190 | 500-700 | 40/30 | 200 |

We can see that,12X18H10T and AISI 321 have the almost the same chemical compositions

12X18H10T is with less than 0.012% carbon,and AISI 321 with Maxiumim 0.08% Carbon.

As a conclusion,AISI 321 can be used to replace 12X18H10T marterial. Both grade has good heat resistance performance.

Good oxidation resistance in intermittent service to 900 °C and in continuous service to 925 °C. These grades perform well in the 425-900 °C range, and particularly where subsequent aqueous corrosive conditions are present.

Equivalent Grades of 12X18H10T

| Standard | Equivalent Grade |

|---|---|

| GOST | 12X18H10T (12Х18Н10Т) |

| AISI (USA) | 321 |

| EN (Europe) | X6CrNiTi18-10 (1.4541) |

| DIN (Germany) | 1.4541 |

| ISO | X6CrNiTi18-10 |

Want to learn more about the equivalent grade of Gost steel material?

Pls refer to International Steel equivalents Gost Steel material ASME DIN Material Comparison.pdf