ASTM A358 Tp316L CL 1 EFW Welded Pipe Manufacturer

ASTM A358 is the specification for electric fusion welded (EFW) austenitic stainless steel pipe suitable for high-temperature and corrosive environments.

316L, TP316L ,TP316L (Type 316L) Stainless Steel is low-carbon version of 316 stainless steel.

Lower carbon content (≤ 0.03%) helps prevent carbide precipitation, reducing the risk of intergranular corrosion.Contains molybdenum (Mo) (2-3%) for improved corrosion resistance, especially against chloride environments (e.g., seawater and acidic chemicals).

ASTM A358 316L Pipe Manufacturing Process:

- Electric Fusion Welding (EFW)

- Longitudinally welded stainless steel pipes

- Pipes may be single- or double-welded

- Radiographic examination (X-ray testing) may be required depending on the class

Pipe Classes:

ASTM A358 has 5 classes based on heat treatment and welding processes:

| Class | Description |

|---|---|

| Class 1 | Fully radiographed, welded, and heat-treated after welding |

| Class 2 | Welded with no radiography but heat-treated |

| Class 3 | Similar to Class 1 but welded using filler metal |

| Class 4 | Similar to Class 2 but welded using filler metal |

| Class 5 | Double-welded, fully radiographed, and heat-treated |

A358 316L Chemical Composition:

ASTM A358 TP316L pipe is made from A240 316L plate,so the compostion of the material follow the requirement of ASTM A240

ASTM A240 316L Plate Chemical Composition (wt%) limits as specified in ASTM A240 and ASME SA240*

| Element | 316 | 316L |

| Carbon | 0.08 | 0.030 max |

| Chromium | 16.0-18.0 | 16.0-18.0 |

| Nickel | 10.0-14.0 | 10.0-14.0 |

| Molybdenum | 2.00-3.00 | 2.00-3.00 |

| Manganese | 2.00 | 2.00 |

| Silicon | 0.75 | 0.75 |

| Nitrogen | 0.10 | 0.10 |

| Phosphorus | 0.045 | 0.045 |

| Sulfur | 0.030 | 0.030 |

A358 TP316L Mechanical Property

ASTM A358 TP316L pipe is made from A240 316L plate,so the Mechanical propety of the material follow the requirement of ASTM A240

Mechanical property requirements for annealed product as specified in ASTM A240 and ASME SA240

| Property | 316 | 316L |

| Yield Strength, min. (ksi) | 30 | 25 |

| Tensile Strength, min. (ksi) | 75 | 70 |

| Elongation, min. (%) | 40 | 40 |

| Hardness, max. (Rb) | 95 | 95 |

Dimensions & Tolerances:

- Available in various sizes & schedules ( 10S, 40S, 80S, etc.)

- Outer Diameter (OD): 8″ to 48″ (1200mm) or larger

- Wall Thickness: Based on ASME B36.19 (for stainless steel)

- Length:6-12 meters

- Dimension tolerance:

- Permissible Variations—The dimensions at any point in a length of pipe shall not exceed the following:

- 8.1.1 Outside Diameter—Based on circumferential measurement, 60.5 % of the specified outside diameter.

- 8.1.2 Out-of-Roundness—Difference between major and minor outside diameters, 1 %.

- 8.1.3 Alignment—Using a 10-ft [3-m] straightedge placed so that both ends are in contact with the pipe, 1⁄8 in. [3 mm] deviation from contact with the pipe.

- 8.1.4 Thickness—The minimum wall thickness at any point in the pipe shall not be more than 0.01 in. [0.3 mm] under the nominal thickness

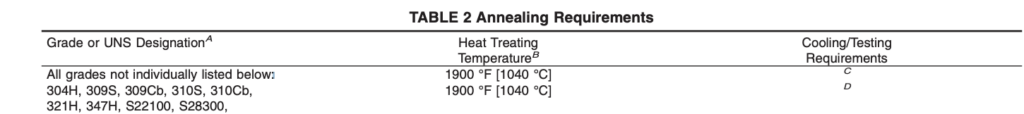

Heat Treatment requirement of A358 Tp316L pipes

Testing Requirements:

- Hydrostatic Test (Pressure test)

- Non-Destructive Testing (NDT) (for radiographed classes)

- 100% Radiographic Inspection of the weld

- Eddy Current Testing

- Intergranular Corrosion Test (for sensitization resistance)

- PMI (Positive Material Identification) if required

Typical Applications of A358 Grade 316L Pipes.

- Chemical and petrochemical plants

- Desalination and marine piping

- Pulp and paper industry

- High-purity water and clean steam

Want to learn about the difference between ASTM A312 and A358 TP316L Pipes?