Understand the standard ASTM A312 and ASTM A358

ASTM A312 and ASTM A358 are both ASTM specifications for austenitic stainless steel pipes.They specified the same stainless steel grade Tp304/304L/304H,Tp316/316L/316H,TP321/321H,TP347/347H etc

ASTM A312 covers seamless, straight-seam welded, and heavily cold-worked austenitic stainless steel pipes, making it versatile for various applications. In contrast, ASTM A358 specifies electric-fusion-welded austenitic chromium-nickel stainless steel pipes, designed for specific welding requirements in high-temperature and corrosive environments.

In this article, we will discuss the difference between ASTM A312 and ASTM A358 in the manufacturing processes, and material properties,and Dimension tolerance,Application etc.

ASTM A312

Standard Specification for Seamless and Welded Austenitic Stainless Steel Pipes

Production method:

Seamless (SML) pipe shall be made by a process that does not involve welding at any stage of production.6.1.3 Welded (WLD) pipe shall be made using an automatic welding process with no addition of filler metal during the welding process.

Heavily cold-worked (HCW) pipe shall be made by applying cold working of not less than 35 % reduction in thickness of both wall and weld to a welded pipe prior to the final anneal. No filler shall be used in making the weld. Prior to cold working, the weld shall be 100 % radiographically inspected in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Division 1, latest revision, Paragraph UW-51.

Welded pipe and HCW pipe of NPS 14 and smaller shall have a single longitudinal weld. Welded pipe and HCW pipe of a size larger than NPS 14 shall have a single longitudinal weld or shall be produced by forming and welding two longitudinal sections of flat stock when approved by the purchaser. All weld tests, examinations, inspections, or treatments shall be performed on each weld seam.

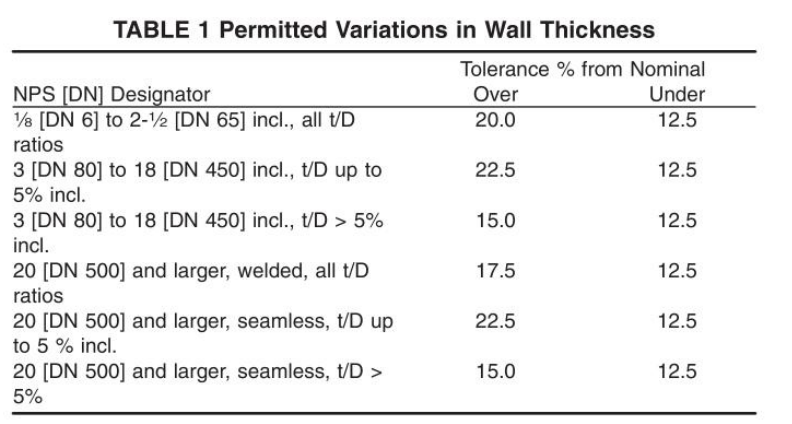

Dimension Tolerance of ASTM A312

ASTM A358

Standard Specification for Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications

Production Method: Welding

The joints shall be full penetration double-welded or single-welded butt joints employing fusion welding processes as defined under “Definitions,” ASME Boiler and Pressure Vessel Code, Section IX

There are 5 classes .

Class 1—Pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

Class 2—Pipe shall be double welded by processes employing filler metal in all passes. No radiography is required.

Class 3—Pipe shall be single welded by processes employing filler metal in all passes and shall be completely radiographed.

Class 4—Same as Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal

Class 5—Pipe shall be double welded by processes employing filler metal in all passes and shall be spot radiographed.

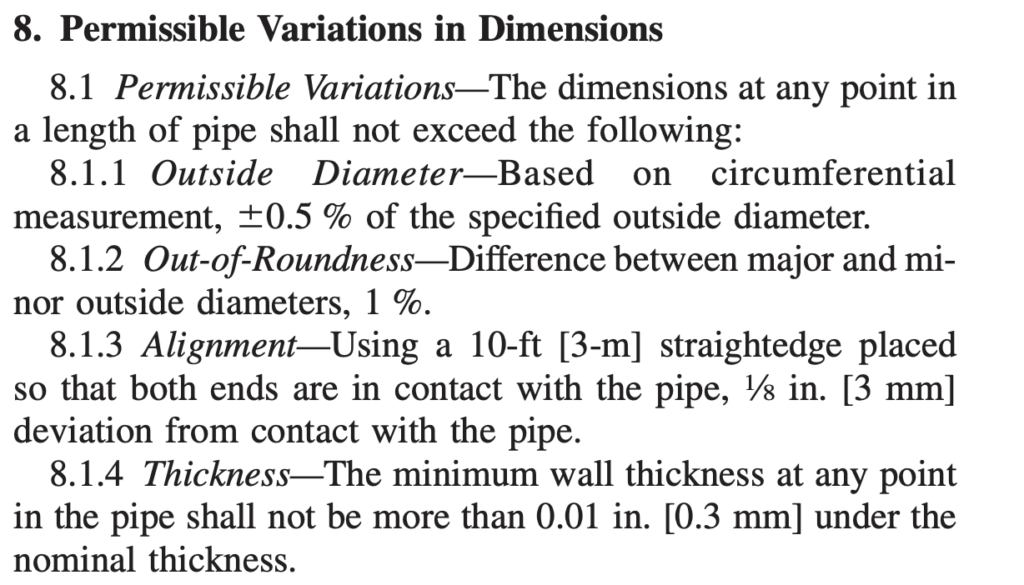

Dimension Tolerance

ASTM A312 vs. ASTM A358 – Comparison Table

| Aspect | ASTM A312 | ASTM A358 |

|---|---|---|

| Pipe Type | Seamless or Welded | Welded only (usually from plate or sheet) |

| Manufacturing Method | Cold or hot finished, welded without filler metal (typically) | Electric Fusion Welded (EFW) with or without filler metal |

| Grades Covered | TP304, TP316, TP321,Tp347/H etc. | TP304, TP316, TP321,Tp347/H etc |

| Wall Thickness Range | Standard schedules (e.g., Sch 10, 40, 80) | Often for larger diameters and heavier wall thicknesses |

| Pipe Sizes | Nominal Pipe Size (NPS) 1/8″ to 30″ | Usually NPS 8″ and above |

| Dimension Tolerance | As per A999 | Accoridng to ASTM A358 |

| Typical Applications | High-pressure piping, chemical, food industry | Low-pressure steam, condensate, or structural applications |

Conclusion:

In the actual pratices,customer always accepts to use the seamless pipe to subsituate the weld pipes.because seamless pipes have a better performance because of “No Welding Seam”.So many cases, for example,A312 TP316L pipes can replace ASTM A358 TP316L pipes. And A312 grade TP347 pipes to replace ASTM A358 TP347 Welded Pipes.but the important Note should be reminded,and get approval from customer first.

The thickness tolerance are different between ASTM A312 and ASTM A358 ,A358 has a more strict wall thickness requirement, maximum Minus 0.3mm of the nominal wall thickness.

⬇️ Download ASTM A312 and ASTM A358 Comparison specification Now (PDF)