ASME SA312 TP347 347H PIPE Manufacturer

We are a trusted manufacturer, stockist, and exporter of ASME SA312 TP347 and TP347H stainless steel pipes, engineered for high-temperature and corrosive environments. These austenitic stainless steels, stabilized with columbium (niobium), are ideal for use in pressure vessels, heat exchangers, petrochemical plants, and power generation systems.

We supply seamless and welded TP347 / TP347H pipes in compliance with ASME SA312 and ASTM A312 standards, with full material traceability and test certification.

ASTM A312: Specification for seamless, welded, and heavily cold-worked austenitic stainless steel pipes for high-temperature and corrosive environments.

TP347: A stabilized stainless steel alloy — basically Type 304 + Columbium (Niobium).

Tp347 is an austenitic stainless steel stabilized with columbium. The addition of columbium makes this stainless grade perfect performance at high oxidation condition under high temperatures at around 800 degrees Celsius

TP347H (UNS S3409) is the stainless steel grade of TP347 with a higher carbon content(0.04 – 0.10)

347H has good resistance to intergranular corrosion, and has good corrosion resistance in alkali, seawater and a variety of acid solutions. Due to its good heat resistance and oxidation resistance, it can withstand small loads at temperatures below 850 degrees.

Other Product also available in 347/347H grade

A403 WP347/347H Pipe fittings

ASTM A312 TP347/347H Pipe specfication

- Size Range: NPS 1/8″ to 30″

- Wall Thickness: Schedules 5S to XXS

- Dimension Standard:ASME B36.19, Tolerance to ASTM A999

- Ends: Plain End (PE), Beveled End (BE)

Chemical compostion of TP347/347H

| Element | TP347 (%) | TP347H (%) |

|---|---|---|

| Carbon (C) | ≤ 0.08 | 0.04 – 0.10 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 |

| Chromium (Cr) | 17.0 – 19.0 | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 13.0 | 9.0 – 13.0 |

| Niobium (Cb/Ta) | ≥ 10xC (approx. 0.3–1.0) | ≥ 10xC (approx. 0.3–1.0) |

Mechanical Property of TP347/347H

TP347 and TP347H share the same mechanical properties according to ASTM A312

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 75 ksi (515 MPa) |

| Yield Strength (0.2%) | ≥ 30 ksi (205 MPa) |

| Elongation (%) | ≥ 35% (in 2 inches) |

| Hardness (HRB) | ≤ 90 |

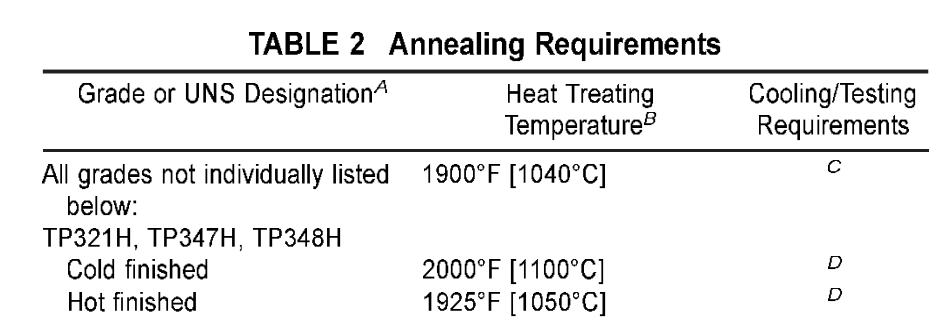

ASTM A312 Tp347/347H Pipe Heat Treating Condition

The annealing temperature range for TP347 is upt 1900°F (1040°C). While the primary purpose of annealing is to obtain softness and high ductility

Testing & Inspection Requirements of stainless steel pipes

- Hydrostatic Test or Nondestructive Examination (NDE)

- Tensile & Flattening Tests

- Visual & Dimensional Inspection

- PMI (Positive Material Identification)

Applications of TP347/347H

- Heat exchangers and boilers

- High-temperature chemical processing

- Superheaters and reheater tubing in power plants

- Refineries and high-pressure steam systems

- Piping systems exposed to high temps and corrosive fluids

Character of TP 347 or TP 347H

| Property | Details |

|---|---|

| Corrosion Resistance | Excellent, even after welding |

| Temperature Resistance | Very good for high-temp service (up to ~870°C) |

| Weldability | Good — doesn’t require post-weld heat treatment |

| Creep Strength | Better than 304/316 at high temps |

| Formability | Slightly less than 304/316 but still workable |

which grade to select TP 347 or TP 347H?

Basically,TP347 and TP347H share almost the same application because they have very similar compostion.Mechnical Properies.

However,there are some differences between this 2 grades.Here is the thing you need to know to select the right grade.

Select TP347 grade,for better weldability and less risk of sensitization. because of Lower carbon content

Select TP347H grade ,347H has higher carbon content,347H is more resistant to thermal fatigue and long-term deformation. improved creep strength and grain stability.operating temp ≥ 550°C (1022°F) or long exposure at high temps

Frequently Asked Questions (FAQ)

Q: What’s the difference between TP347 and TP347H pipes?

A: TP347H has higher carbon content, giving it better creep resistance at elevated temperatures.

Q: Are ASTM A312 TP347 pipes suitable for welding?

A: Yes. Due to niobium stabilization, TP347 is highly resistant to intergranular corrosion after welding.

Q: Can you supply pipes with NACE MR0175 compliance?

A: Yes, we offer TP347 / TP347H pipes compliant with NACE MR0175 standards.

⬇️ Download ASTM A312 standard Now (PDF)

As a trusted manufacturer and supplier of ASTM A312 / ASME SA312 TP347 and TP347H stainless steel pipes, we offer high-quality seamless and welded tubes for high-temperature and corrosive service. TP347 and TP347H are stabilized austenitic stainless steels ideal for heat exchangers, refinery systems, power generation piping, and pressure vessels.

Our 347H pipes are specially designed with higher carbon content to ensure superior creep strength and high-temperature endurance. All pipes comply with ASTM/ASME standards and are supplied with mill test certificates (MTC), PMI reports, and optional NDT testing.