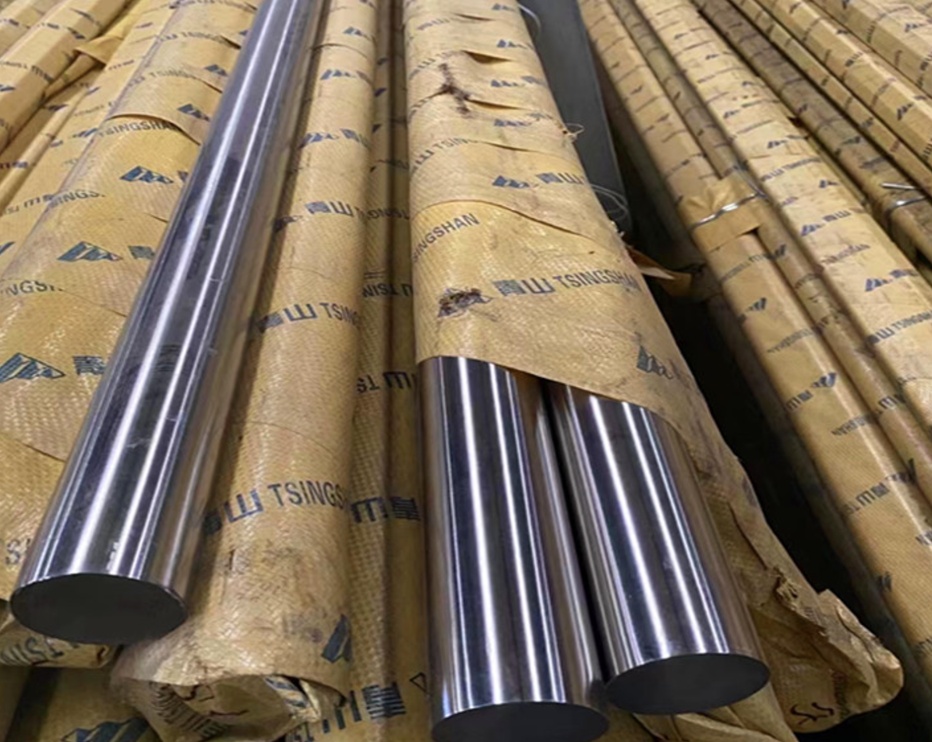

17-4ph S17400 Round Bar Manufcturer

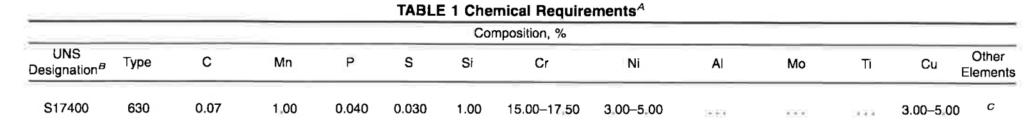

17-4ph is a grade of martensitic precipitation hardened stainless steel. It contains approximately 15–17.5% chromium and 3–5% nickel, as well as 3–5% copper.It also known as below grade.

- UNS S17400

- AISI Type 630

- AMS 5643 / ASTM A564 / ASTM A693

- “17-4 PH” = 17% Chromium, 4% Nickel, Precipitation-Hardened

17-4PH stainless steel is a kind of martensitic precipitation hardening stainless steel developed by adding Cu, Nb and other strengthening elements on the basis of Cr17 stainless steel, and its strength is mainly due to martensite phase transformation and precipitation hardening of ε-Cu, NbC, M23C6 and other aging hardening phases in the aging temperature range.

17-ph round bar is a raw material to produce the UNS S17400 stud bolt

Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

UNS S17400 Chemical Compostion according to ASTM A564

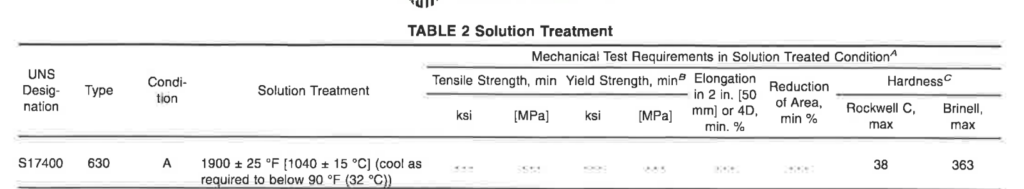

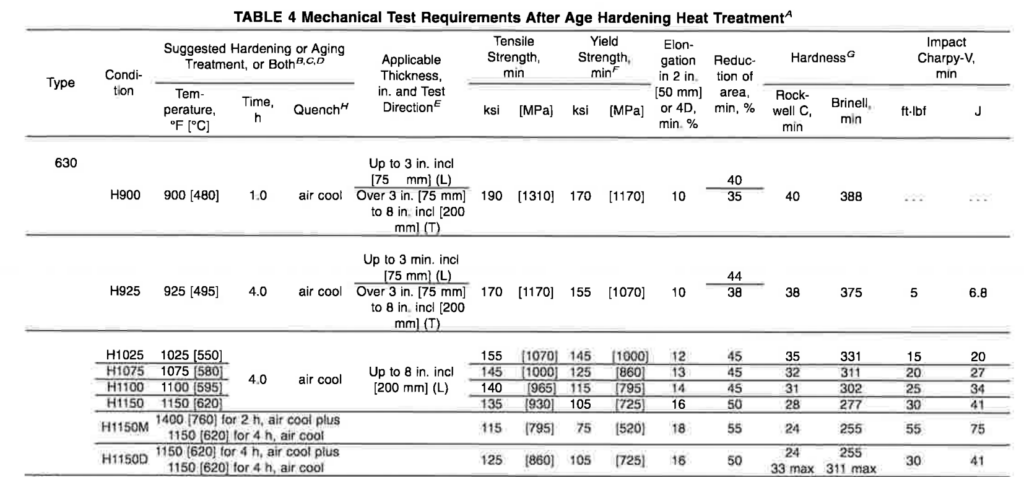

UNS S17400 Heat treatment and Hardness

17-4ph,grade 630 mechanical Property

17-4ph Round Bar size range

- Diameter Range: 3 mm to 300+ mm (1/8” to 12”+)

- Lengths: 1 meter, 3 meter, 12 ft standard; or custom cut

- Tolerances: as per ASTM/AMS specs

Why 17-4ph S17400 round bar?

Corrosion resistance

The corrosion resistance of the 17-4 PH alloy is superior to that of any other standard hardenable stainless steel. In most cases, it is no less resistant to corrosion than 304.

If there is a risk of stress corrosion cracks, a higher maturation temperature must be higher than 550 °C (1022 °F), preferably 590 °C (1094 °F).

The optimal tempering temperature in chloride media is 550°C-1022°F.

The optimal tempering temperature in H2S media is 590°C-1094°F.