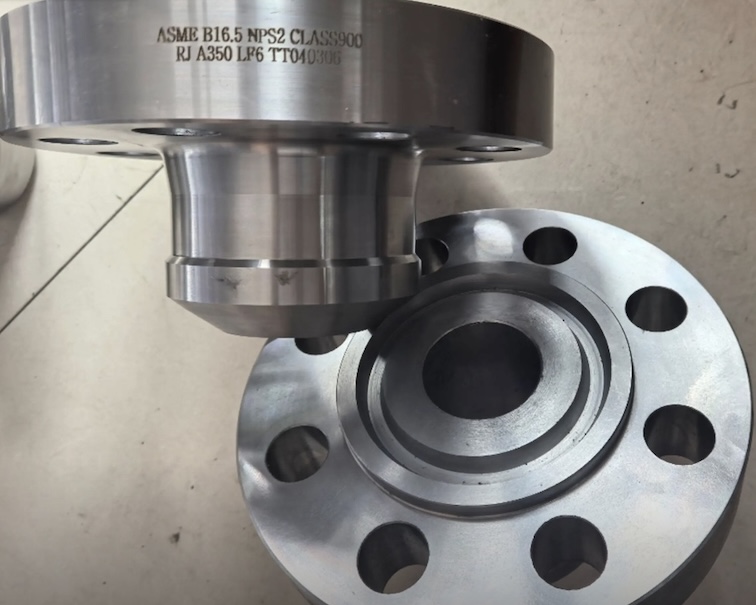

ASTM A350 LF2 and LF6 difference

Both ASTM A350 LF2 and ASTM A350 LF6 are low-temperature carbon steel forging grades commonly used in piping components like flanges, fittings, and valves.Two materials are specified under ASTM A350/ASTM A350M Standard.(Download the ASTM A350 PDF standard)

In this page,you woud find the difference between ASTM A350 LF2 and ASTM A350 LF6

ASTM A350 LF2 and LF6 Chemical Composition Comparison

We can see that, grade LF6 has a lower Carbon content Max 0.22%, than Grade LF2,and LF6 requests a higher Minimum Manganese content 1.15% ,which could make LF6 a stronger mechanical property..additionally,Nitrogen element is required in LF6, specifed from 0.01-0.030%

ASTM A350 LF2 and LF6Chemical Composition Comparison (ASTM A350)

| Element | LF2 (Composition, wt. %) | LF6 (Composition, wt. %) |

|---|---|---|

| Carbon (C) | Max 0.30 | Max 0.22 |

| Manganese (Mn) | 0.60 – 1.35 | 1.15 – 1.50 |

| Phosphorus (P), max | 0.035 | 0.025 |

| Sulfur (S), max | 0.040 | 0.025 |

| Silicon (Si) | 0.15 – 0.30 | 0.15 – 0.30 |

| Nickel (Ni) | Max 0.40 | Max 0.40 |

| Chromium (Cr) | Max 0.30 (Note B,C) | Max 0.30 (Note B,C) |

| Molybdenum (Mo) | Max 0.12 (Note B,C) | Max 0.12 (Note B,C) |

| Copper (Cu) | Max 0.40 (Note B) | Max 0.40 (Note B) |

| Niobium (Nb / Columbium) | Max 0.02 (Note D) | Max 0.02 (Note D) |

| Vanadium (V) | Max 0.08 | 0.04 – 0.11 |

| Nitrogen (N) | Not specified | Max 0.030 |

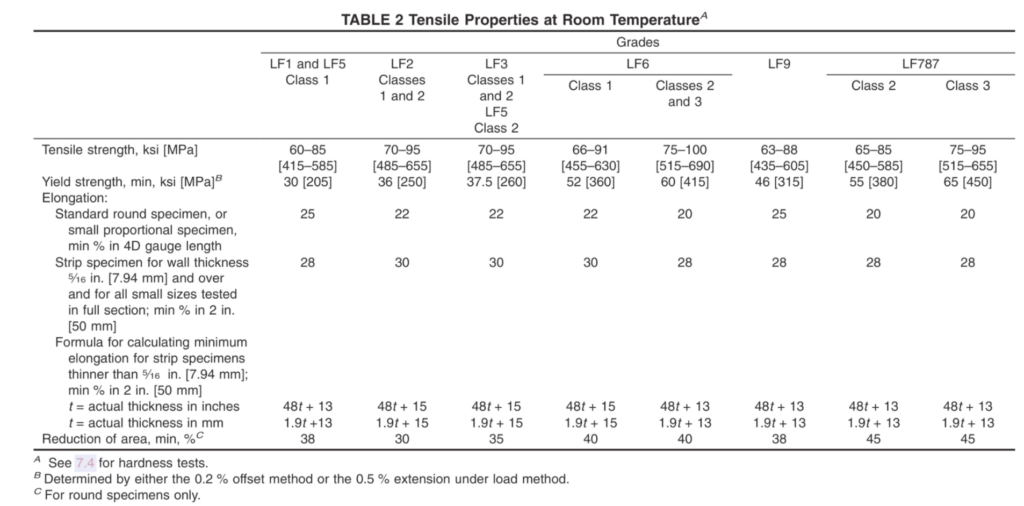

ASTM A350 LF2 and LF6 Mechnical Properties Comparison

There are 3 grades of LF6,Class 1,Class 2,Class 2&3 have a higher tensile and yield strength as below

LF2 (Class 1 / Class 2)

LF6 (Class 1, Class 2, Class 3)

Mechanical Differences

| Property | LF2 | LF6 | Difference |

|---|---|---|---|

| Tensile Strength | 70–95 ksi | 66–100 ksi | LF6 (Class 2&3) higher |

| Yield Strength | 36 ksi | 52–60 ksi | LF6 much stronger |

| Elongation | 22% | 20–22% | LF6 slightly lower (Class 2&3) |

| Reduction of Area | 30% | 35–40% | LF6 stronger & tougher |

| Overall Strength | Medium | High | LF6 superior |

| Low-temp toughness | Good | Excellent | LF6 better toughness |

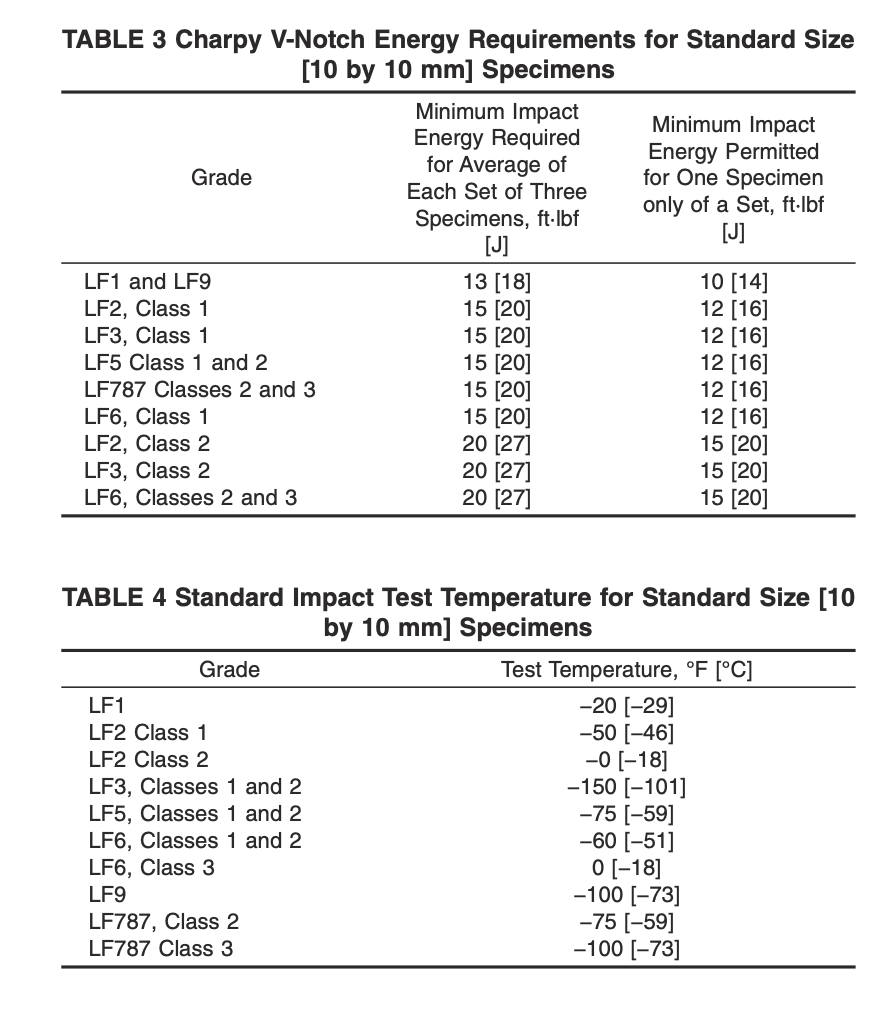

Chapry V-Notch Energy Requirement

All the materials under ASTM A350 are required with Chapry V-Notch impact testing.

LF6 Class 1 & 2 are tested at a lower temperature (−60°F / −51°C) than LF2 Class 1 (−50°F / −46°C) → meaning higher toughness at colder temperatures. LF2 Class 2 and LF6 Class 3 both tested at 0°F (−18°C).

Hardness Test:

Both LF2 and LF6 has the same hardness requirement, not exceed 197 HBW after heat treatment for mechanical properties

Heat Treatment Comparion

Forgings of grades LF2 and LF6 shall be furnished in the normalized, or normalized and tempered, or quenched and tempered condition. At the option of the manufacturer, forgings furnished in the quenched and tempered condition may be normalized prior to the austenitize/quench operation.

Summary of LF2 and LF6 comparison

LF2 is the most commonly used LTCS forging grade, cost-effective and suitable for most low-temperature piping systems (e.g., carbon steel valves, flanges, pressure vessels).

LF6, with added Nitrigon,more strict requirement of Carbon content and Maganese, offers improved toughness and ductility at low temperatures, making it a preferred choice for more demanding environments like cryogenic or offshore service.

Typical Products made of ASTM A350 LF2 and ASTM A350 LF6

- Flanges (Weld Neck, Blind, Slip-On, Threaded, etc.)

- Forged fittings (Socket Weld, Tees, Elbows, Couplings)

- Forged bars and blocks

- Valve bodies and parts

- Shafts, rings, discs