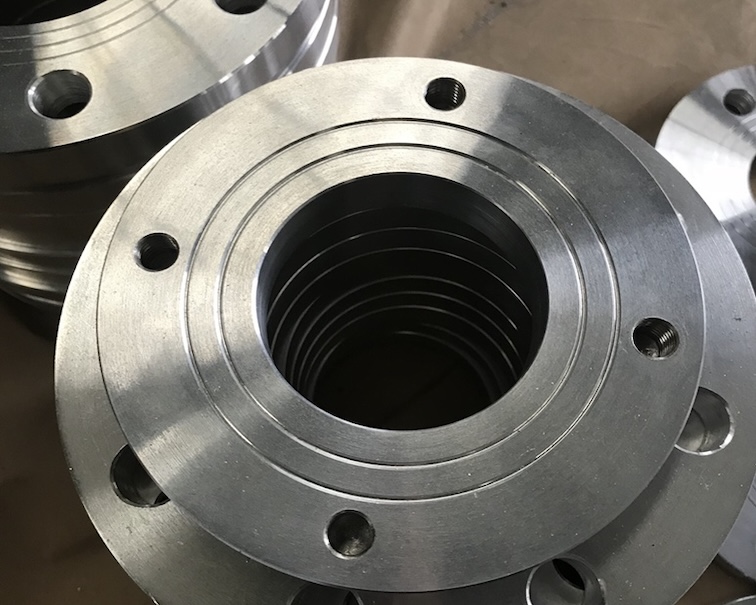

ASTM A350 LF3 Flanges,Forgings Manufacturer

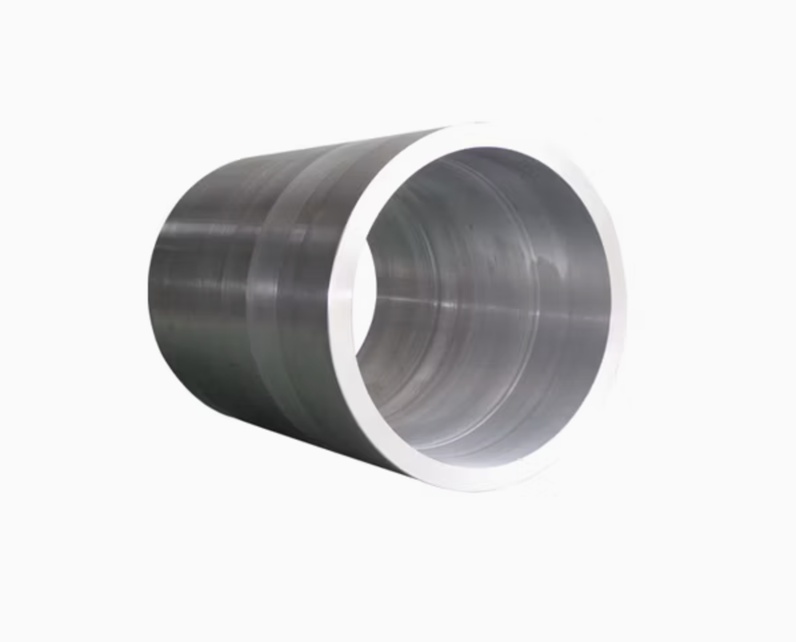

ASTM A350 LF3 are low-temperature carbon steel forged flanges, specifically designed for use in cryogenic and subzero environments. LF3 is a nickel grade (3.3–3.7%), making it suitable for colder service than LF2 or LF6

There are 2 classes in ASTM A350 LF3,Class 1and Class 2, they have the same composition but Class 2 has a higher impact testing value than Class 1.

Characteristics of ASTM A350 LF3 Flanges

- Material Type: Forged carbon steel with nickel content added(3.3–3.7%)

- Application: Low-temperature service (down to −150°F / −101°C)

- Standard: ASTM A350 / A350M

- Heat Treatment: Normalized, normalized and tempered, or quenched and tempered

- Grain Size: As per ASTM and ISO standards

- Impact Testing: Required at low temperatures

Chemical Composition of ASTM A350 LF3 forgings

| Element | Composition |

|---|---|

| Carbon, max | 0.20 max |

| Manganese | 0.90 max |

| Phosphorus, max | 0.035 max |

| Sulfur, max | 0.040 max |

| Silicon [Note A] | 0.20–0.35 |

| Nickel | 3.3–3.7 |

| Chromium | 0.30 max [Note C] |

| Molybdenum | 0.12 max [Note C] |

| Copper | 0.40 max |

| Columbium | 0.02 max |

| Vanadium | 0.03 max |

Mechanical & Impact Properties of ASTM A350 LF3

| Property | Value (Typical) |

|---|---|

| Yield Strength | ≥ 260 MPa |

| Tensile Strength | ≥ 485 MPa (70 ksi) |

| Elongation | ≥ 30% |

| Charpy Impact Energy | 20 ft·lbf [27 J] avg at −150°F [−101°C] for LF3 Class 2 15 ft·lbf [20 J] avg at −150°F [−101°C] for LF3 Class 1 |

Hardness of ASTM A350 LF3

not exceed 197 HBW after heat treatment for mechanical properties

heat treatment of ASTM A350 LF3

Forgings of grades LF3 shall be furnished in the normalized, or normalized and tempered, or quenched and tempered condition. At the option of the manufacturer, forgings furnished in the quenched and tempered condition may be normalized prior to the austenitize/quench operation.

ASTM A350 LF3 flanges availability:

ASTM A350 LF3 flanges are available in the full range of forged flange types:

| Flange Type | Description |

|---|---|

| Weld Neck (WN) | For high-pressure & high-temp applications |

| Slip-On (SO) | Easy to align, welded both sides |

| Blind (BL) | Seals pipe ends, often pressure-rated |

| Socket Weld (SW) | For small bore piping, internal welding |

| Threaded (THD) | For piping without welding |

Standard available for LF3 flanges

ASTM A350/A350M Covers carbon and low-alloy steel forged flanges, fittings, valves for LT service

ASME B16.5 Flange dimensions and pressure-temperature ratings (NPS ½” to 24″)

ASME B16.47 For large diameter flanges (NPS 26″ to 60″)

MSS SP-44 / API 605 Steel flanges for pipeline systems (alternative for large sizes)

Typical Applications

- LNG terminals

- Gas processing plants

- Cryogenic piping systems

- Subsea pipelines

- Low-temperature pressure vessels

need a dimension chart, MTC sample, or flange weight chart for ASTM A350 LF3 Flanges?Pls drop a mail.

Want to know the difference between ASTM A350 LF2 Flanges and ASTM A350 LF3 Flanges?