ASME SA266 Gr.2 Forged Flanges Manufacturer

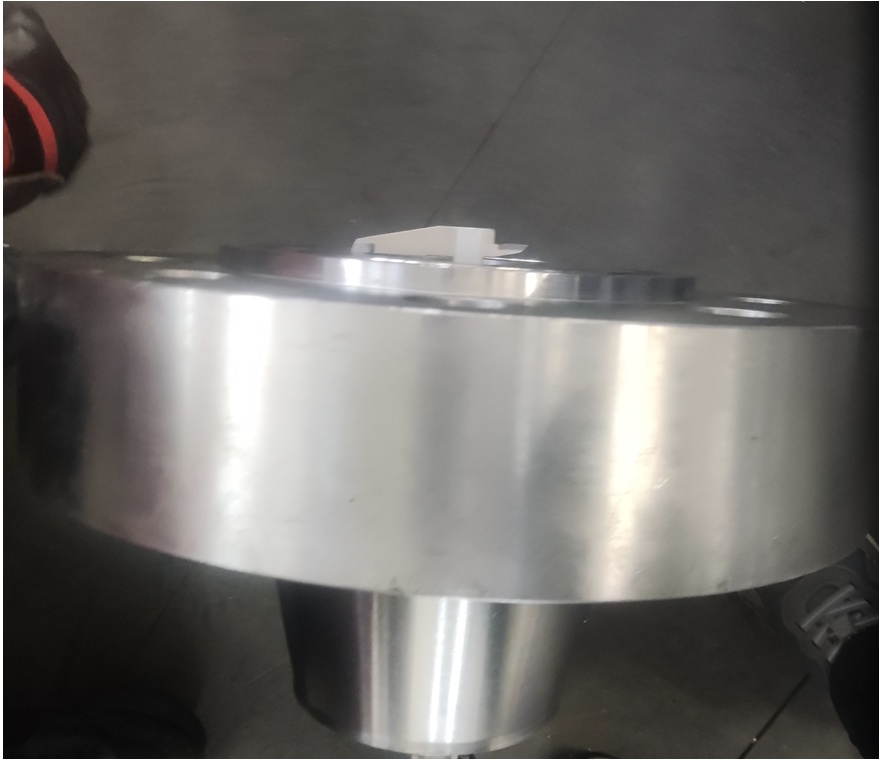

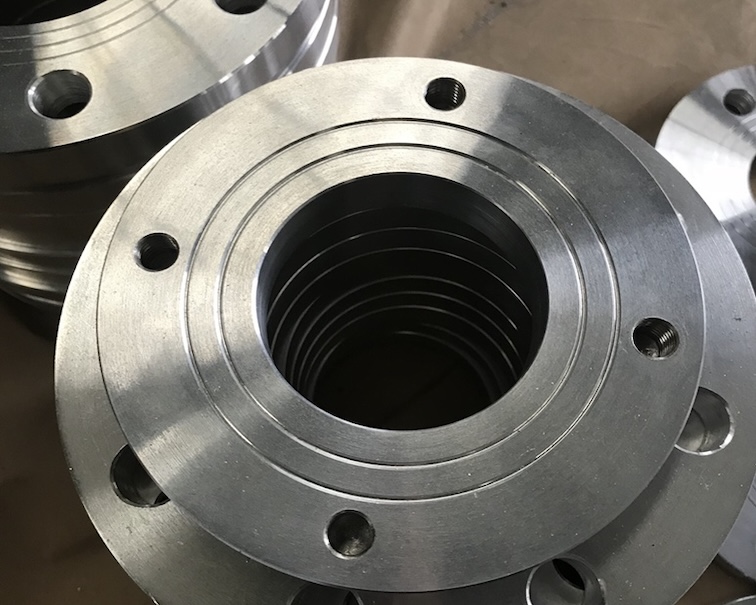

We specialize in manufacturing and supplying ASME SA266 Gr.2 forged flanges ,ASME SA266 Gr.2 Girth Flanges

ASTM A266 Grade 2 flanges are forged carbon steel components designed for use in boilers, pressure vessels, and related high-temperature and high-pressure applications. These flanges are known for their durability and mechanical strength.

Flange type available in material SA266 Gr.2

Weld Neck Flanges (WNRF)

Slip-On Flanges (SORF)

Socket Weld Flanges (SWRF)

Blind Flanges (BLRF)

Threaded Flanges

Lap Joint Flanges

Long Weld Neck Flanges

Girth Flanges

Flange Standard Available in material SA266 Gr.2

Sizes, Standards & Pressure Ratings

- Size Range: ½″ to 60 ″ nominal bore (NB)

- Standards: ANSI/ASME B16.5, B16.47 Series A & B, BS4504, EN-1092, DIN,

- Pressure Classes: 150#, 300#, 600#, 900#, 1500#, 2500#,

ASME SA266 Gr. 2 /ASTM A266 Gr. 2 is a low to intermediate forged carbon steel grade that is commonly used for pressure vessel components such as tubesheets, flanges, and fittings.

ASTM A266 Grade 2 Chemical Composition:

| Standard | SA266 Gr.2 |

| Chemical composition(%) | |

| Carbon (C) | 0.30 max |

| Manganese (Mn) | 0.40~1.05 |

| Phosphorus (P) | 0.025 max |

| Sulfur (S) | 0.025 max |

| Silicon (Si) | 0.15~0.35 |

| Tensile Strength (MPa) | 485~655 |

| Yield Strength (MPa) | 250 min |

| Elongation (%) | 18 min |

| Reduction Area (%) | 33 min |

Mechanical Property

| Mechanical properties | Grade 2 |

| Tensile strength, min. Mpa | 485-655 |

| Yield strength, min. Mpa | 250 |

| Elongation in. 2 or 50 mm, min, % | 20 |

| Reduction of area, min. % | 33 |

Applications

ASTM A266 Grade 2 flanges are widely used in industries such as:

- Petrochemical and chemical

- Power generation

- Shipbuilding

- Spare parts for Heat exchangers

Standard Testing Requirements for ASME SA266 Grade 2 Forged Flanges

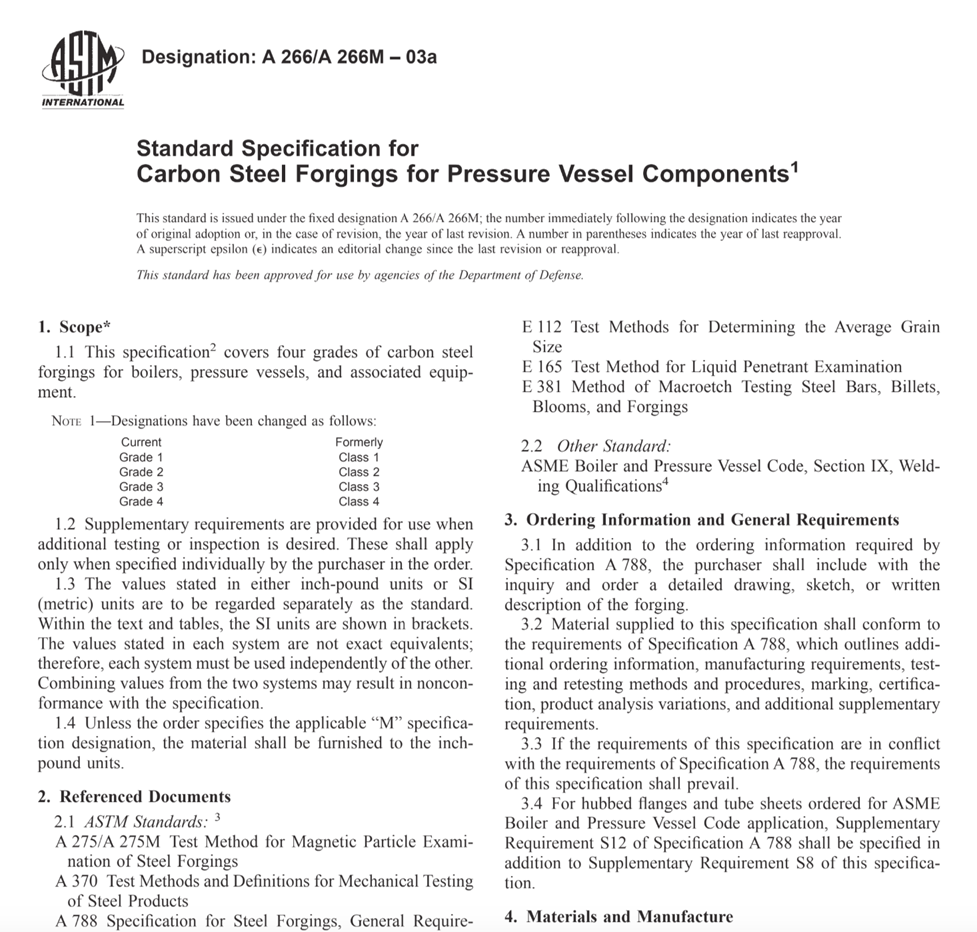

According to the ASTM A266/A266M specification, the following tests and inspections are mandated for SA266 Grade 2 forged flanges:

1. Chemical Analysis

- Heat Analysis: Performed on samples taken according to Specification A788/A788M to ensure compliance with chemical composition requirements.

- Product Analysis:

2. Mechanical Testing

3. Hardness Testing

4. Supplementary Requirements

The specification provides several supplementary requirements that may be invoked by the purchaser:

- S4: Magnetic Particle Examination

- S5: Liquid Penetrant Examination

- S9: Hardness Testing

- S10: Grain Size Determination

- S13: Impact Tests

Want to know Difference between ASME SA 105 and SA266 Gr.2 ?

Both ASME SA105 and ASME SA266 are the most common grade for forgings . Both of these are carbon steel grades used in various high-pressure applications, but they have distinct properties and uses.