ASME SA105 vs ASTM A105 What’s the Difference?

When The engineer select the forged carbon steel materials for flange or parts pressure vessels, They may easily find ASME SA105 and ASTM A105. While they seems the same material grade.Are they exactly the same? In this page,you would get the answer and understand their differences to ensure the compliance, especially in regulated industries like oil & gas, petrochemical, and power generation.

What is ASTM A105?

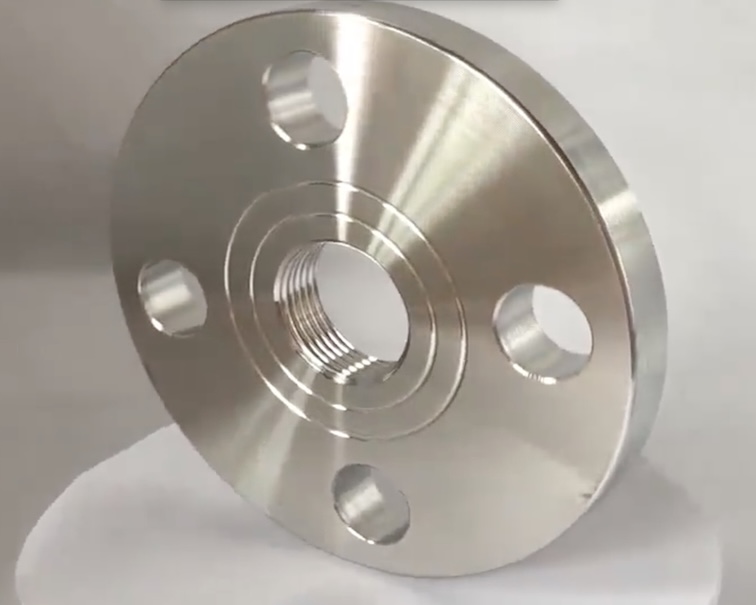

ASTM A105 is a standard specification for forged carbon steel piping components such as flanges, fittings, and valves. It’s widely used in industrial and commercial piping systems that operate at ambient to high temperatures.

ASTM A105 Materials Specification

- Chemical Composition: ASTM A105 mandates specific limits on elements to maintain the material’s suitability for high-pressure and high-temperature environments. Key limitations include the sum of copper, nickel, chromium, molybdenum, and vanadium not exceeding 1.00%, and the combined chromium and molybdenum content being less than 0.32%.

- Mechanical Properties: The material must exhibit minimum tensile strength of 70 ksi, yield strength of 36 ksi, elongation of 30% for wall thicknesses of 5/16 inch or more, and a maximum hardness of 187 HBW.

- Heat Treatment: Although heat treatment is required conditionally, such as flanges above Class 300. Most popluar heat treatment method is normalizing

- Welding: Welding procedures must align with ASME Boiler and Pressure Vessel Code Section IX to guarantee weld integrity.

- Testing and Inspection: Required tests include tension, hardness, and hydrostatic tests if specified in the order. Hydrostatic tests are optional unless explicitly requested.

| Chemical Composition | |

| Carbon | 0.35 max |

| Manganese | 0.60 – 1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10 – 0.35 |

| Copper | 0.40 max [Note B] |

| Nickel | 0.40 max [Note B] |

| Chromium | 0.30 max [Note B, C] |

| Molybdenum | 0.12 max [Note B, C] |

| Vanadium | 0.08 max |

What is ASME SA105?

ASME SA105 is the ASME Boiler and Pressure Vessel Code (BPVC) equivalent of ASTM A105. they are identical in chemical composition and mechanical properties but is specifically qualified for use in boilers, pressure vessels, and other ASME code applications.

Can ASTM A105 and ASME SA105 materials be used interchangeably?Can we use A105 instead of SA105?

ASTM A105 and ASME SA105 materials are the samein terms of chemical composition and mechanical properties. Both standards specify seamless forged carbon steel piping components used in pressure systems and high-temperature services, making them functionally interchangeable in many application

However, When it comes to code compliance, especially for applications requiring ASME code stamps (e.g., “U” stamp under ASME Section VIII, Division 1), ASME SA105 is typically mandated.

We can supply Dual certified grade ASTM A105 /ASME SA105 ,which mean both grade complied.

Differences Between ASME SA105 and ASTM A105

| Features | ASTM A105 | ASME SA105 |

|---|---|---|

| Published By | ASTM International | ASME (BPVC Section II, Part A) |

| Typical Application | Industrial piping systems | Boilers and pressure vessels |

| Certification | General MTRs (Mill Test Reports) | Required for ASME code compliance |

| Material Properties | Same as SA105 | Same as A105 |

How to select between ASME SA105 vs ASTM A105 Material?

- You can chose ASTM A105 for general industrial applications that do not require ASME code stamping.

- You can select ASME SA105 for pressure vessels, heat exchangers, and steam systems governed by ASME code standards.

Download ASTM A105/A105M-24 Latest Edition (PDF)

Download ASME SA105 latest Edition (PDF)