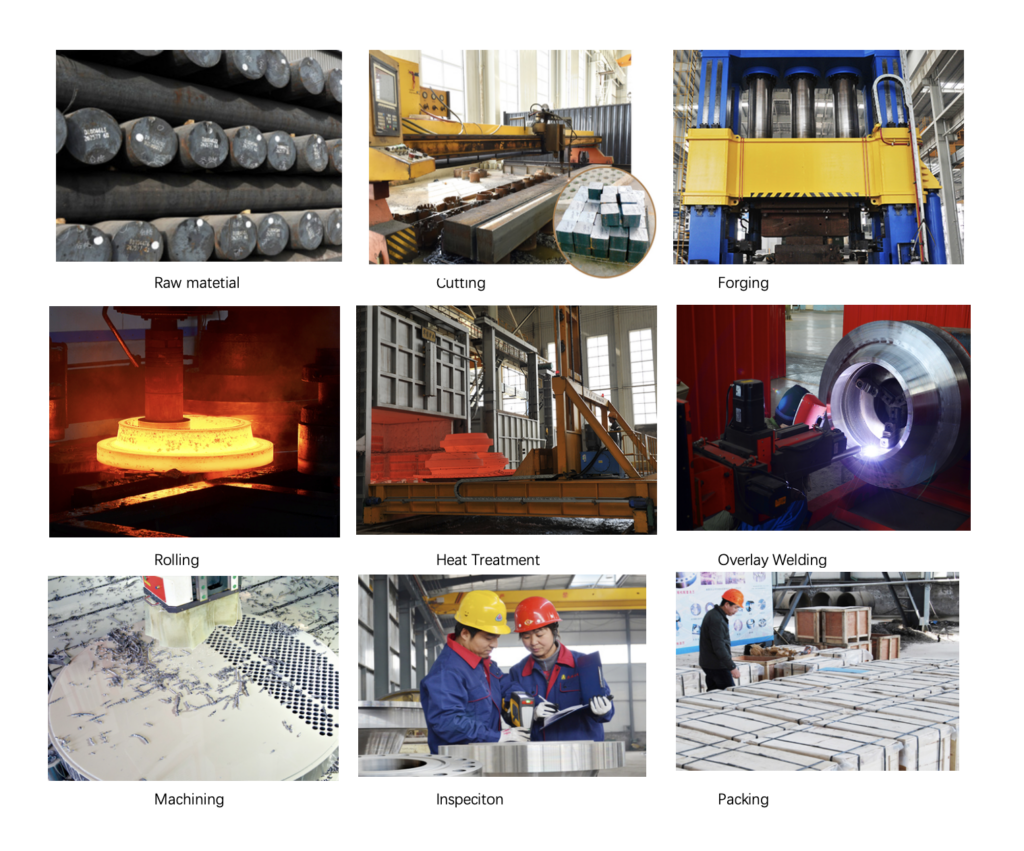

FORGED FLANGES PRODUCTION PROCESS

To Make quality flanges, We should follow manufacturing Process strictly.

Here is the MPS for flanges, Inspection and Testing Plan could be made accordingly.

Phase 1: Material Preparation & Forging

- Step 01 – Raw Material Inspection

- raw materials are received and verified for quality specifications.

- Step 02 – Raw Material Re-inspection

- Secondary quality checks using magnified analysis to detect microscopic defects.

- Step 03 – Slicing

- Materials are precision-cut into workable sections using industrial machinery.

- Step 04 – Forging

- High-pressure forging presses shape the sliced materials into preliminary forms.

- Step 05 – Ring Rolling

- Specialized equipment rolls and forms metal into seamless annular (ring) structures.

Phase 2: Heat Treatment & Machining

- Step 06 – Heat Treatment

- Thermal processing (e.g., quenching/tempering) optimizes mechanical properties like hardness and ductility.

- Step 07 – Machining/Drilling

- CNC machines refine components to exact dimensional tolerances.

- Phase 3: Quality Assurance

- Step 09 – Finished Product Inspection

- Rigorous testing (dimensional, surface, and NDT) ensures compliance with industry standards.

- Step 10 – Packaging

- Certified products are securely packed for damage-free transportation.