DIN 86090 CuNi 90/10 C70600 Elbow Manufacturer

We are a professional manufacturer and exporter of DIN 86090 elbows made from CuNi 90/10 (UNS C70600) copper-nickel alloy. Designed to meet the DIN 86090 standard, these elbows are widely used in marine, shipbuilding, offshore, seawater, and desalination applications where corrosion resistance and long service life are critical.

Fittings for butt welding into copper-nickel-alloy pipelines – Elbows

MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30

DIMENSION : DIN 86090

Type & Construction : SEAMLESS (10 & Below)

SEAM WELDED (12 & Over)

| Published by | Publication Date | Number of Pages |

| DIN | 02/01/2008 | 10 |

A CuNi 90/10 elbow is a pipe fitting formed at a standard angle (90° or 45°) that changes the direction of flow in a piping system. Made from copper-nickel alloy containing approximately 90 % copper and 10 % nickel (UNS C70600), these elbows combine excellent corrosion resistance with good strength—making them indispensable in chloride-bearing and seawater environments.

Chemical composition of Cu Ni 90 10 UNS C70600 Copper Nickel

| Alloy No. | Ni% | Fe% | Mn% | C% | Pb% | S% | P% | Zn% | other imp. | Cu% |

| UNS C70600 | 9.0-11.0 | 1.0-2.0 | 0.5-1.0 | max 0.05 | max 0.02 | max 0.02 | max 0.02 | max 0.50 | max 0.03 | rem. |

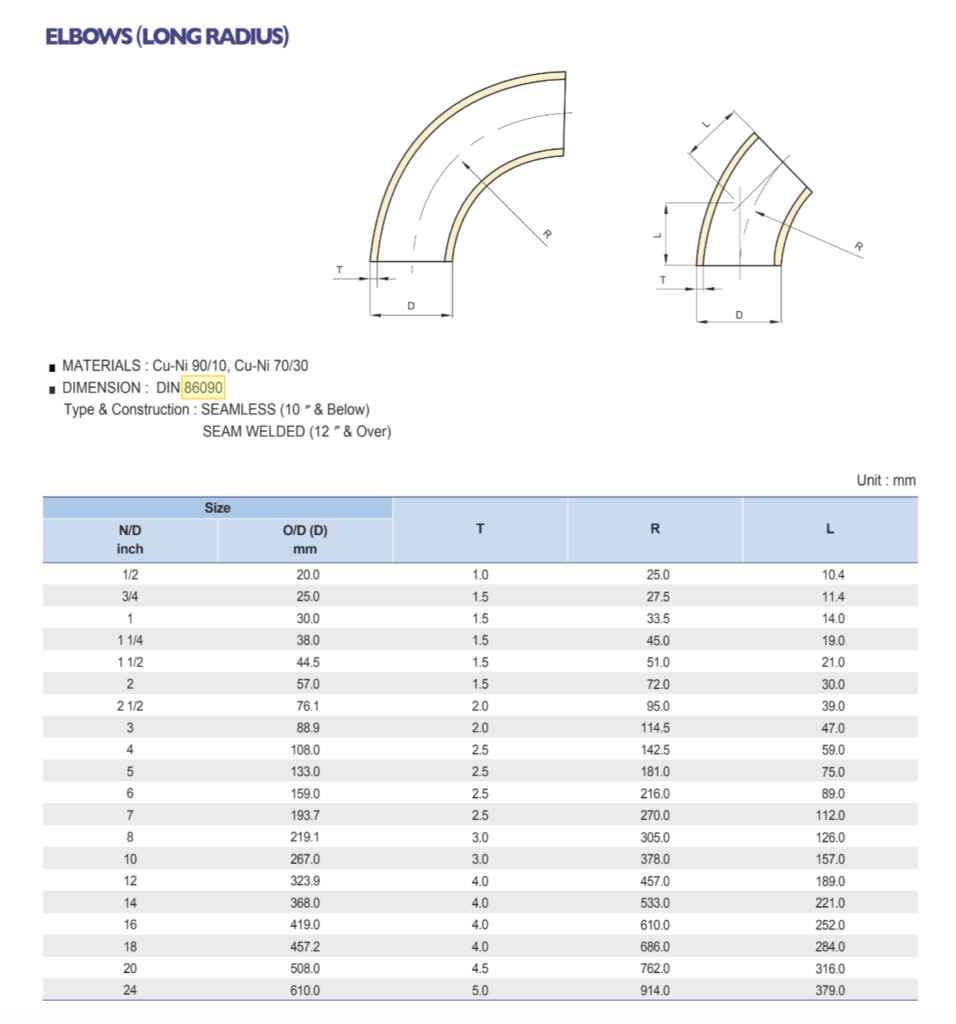

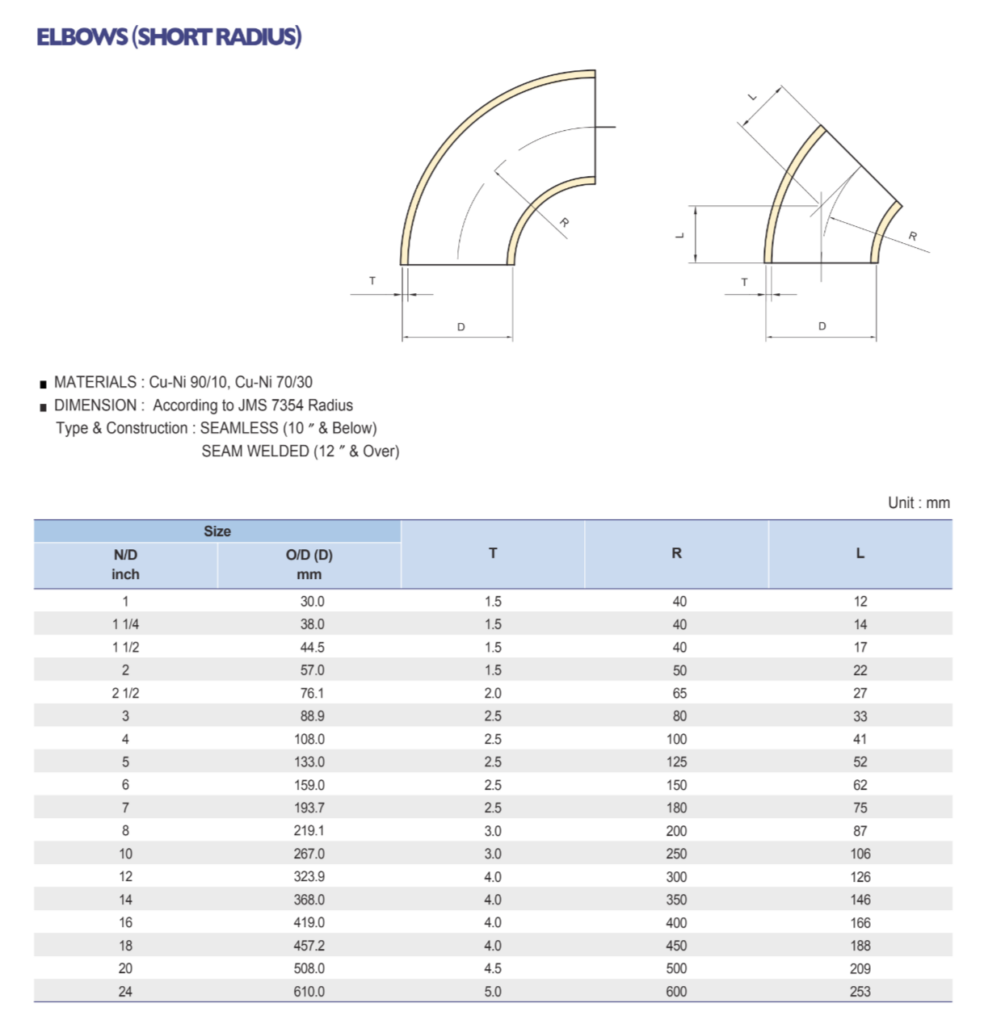

CuNi 90/10 Elbow Dimension according to DIN 86090

Copper Nickel 45° &90° Elbows Long Radius Dimension

Copper Nickel 45° &90° Elbows Short Radius Dimension

Inspection and Testing

Throughout the manufacturing process from melting and alloying to the finished product, stringent quality control inspections and tests are carried out to ensure that product quality complies fully with customers requirements. All tests are performed in accordance with the requirements of the relevent specification. In addition, ultrasonic, radiographic, dye-penetrant, eddy current and other tests can be performed.

For Seam-Welded Fittings it is standard practice to perform 100% radiographic inspection on all welds to ASME, SEC, VIII, UW51; DIN54109, Blatt2 or DIN54111, Teil 1.

Certification

All Butt-Welding Fittings are supplied with a certificate listing the test which have been performed in accordance with relevant specifications and/or customer requests

Download DIN 86019 Elbow Dimension Chart Now (PDF)