DIN 86019 copper nickel C71500 pipe Manufacturer

We are a trusted DIN 86019 Copper Nickel C71500 pipe manufacturer in China, offering premium-quality CuNi 70/30 seamless and welded pipes for demanding marine, offshore, and heat exchanger applications. Our pipes are produced according to DIN 86019 standards, ensuring excellent mechanical performance, corrosion resistance, and reliability in saltwater and seawater environments.

C71500, also known as Copper Nickel 70/30, contains 70% copper and 30% nickel, with added iron and manganese for enhanced resistance to seawater flow, pitting, and erosion.

DIN 86019 C71500 Copper-Nickel Pipe | CuNi 70/30 Seamless Tube

The DIN 86019 specifies seamless copper-nickel tubes for corrosion-resistant service. Our CuNi 70/30 (UNS C71500) pipes with exceptional seawater resistance, erosion control, and mechanical strength ,widely used in marine and industrial system

Seamless tubes made of Bfe 30-1-1/C71500 Tubes for pipes – Dimensions for standard tubes and precision tubes.

BFe 30-1-1 (also known as C71500) is a copper-nickel alloy containing roughly 70 % Cu, 30 % Ni with small additions of Fe and Mn. Its excellent corrosion and erosion resistance in seawater, combined with good strength,

Chemical Composition of C71500 pipes

C71500 Pipes Chemical Composition

| Elements | C71500 |

| Ni% | 29.0-33.0 |

| Fe% | 0.4-1.0 |

| Mn% | Max. 1.0 |

| C% | Max. 0.05 |

| Pb% | Max. 0.02 |

| S% | Max. 0.02 |

| P% | Max. 0.02 |

| Zn% | Max. 0.50 |

| Zr% | – |

| Others | Max. 0.50 |

| Cu% | Balance |

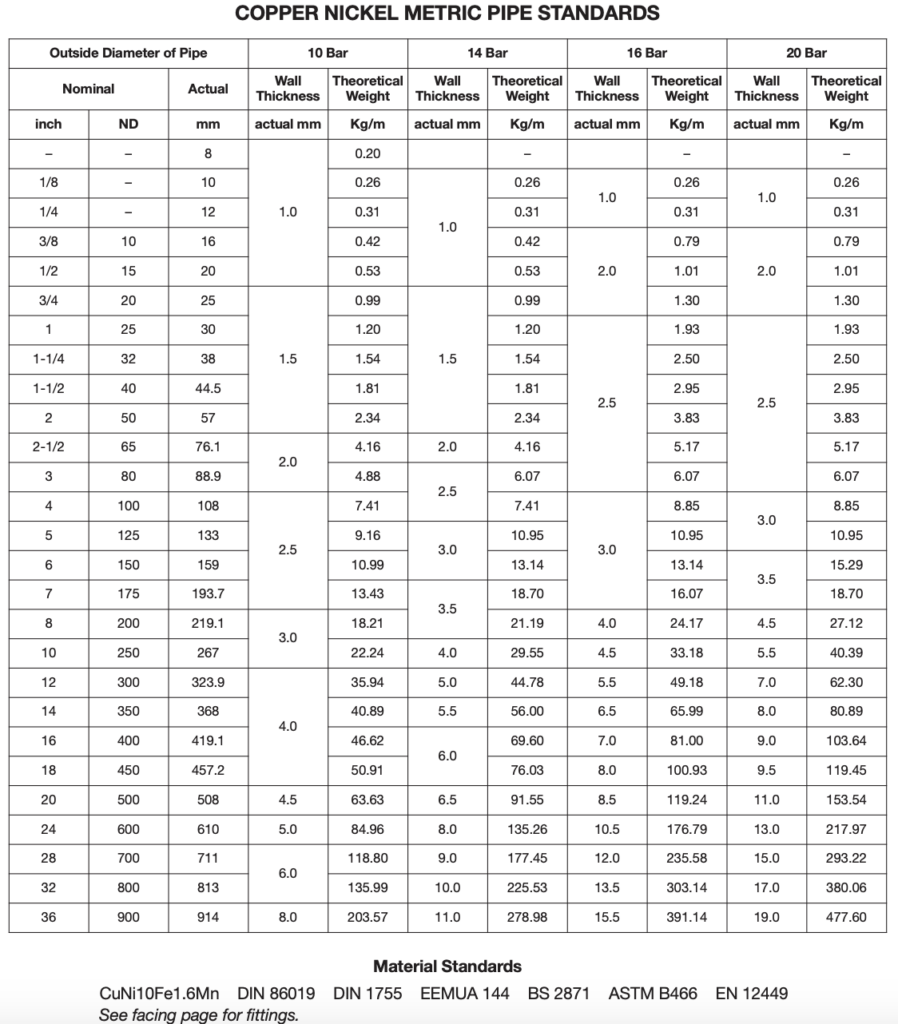

Standards & Dimensions

- Material Specs: DIN 86019

- Size Range:

- Outer Diameter: 10 – 914 mm

- Wall Thickness: 1 – 10 mm (per customer request)

- Lengths: Straight or U-bent up to 18 m

- Testing: 100 % Eddy-Current & Hydraulic Pressure Testing

DIN 86019 C71500 Pipe Dimensions

Typical Applications of C71500 pipe

- Marine & Offshore: Sea-water cooling lines, ballast systems, firefighting loops

- Desalination Plants: Intake, concentrate discharge, and heat-exchange circuits

- Power Generation: Condenser tubes, turbine oil-cooler circuits

- Chemical Processing: Corrosive brine and chloride process piping

Our advantage

- Grades in Stock: BFe 30-1-1 / C71500 (CuNi 70/30)

- Certifications: EN 10204 3.1/3.2 Mill Test Reports, Eddy-current & Hydro tests

- Customization: Special diameters, wall thicknesses, U-bends, and cut-to-length options available

As a leading DIN 86019 copper nickel pipe supplier, we offer world-class CuNi 70/30 tubes with quick delivery, global shipping, and full traceability. Contact us today for a free quote or technical consultation.