ASTM A182 F44 flange Manufacturer

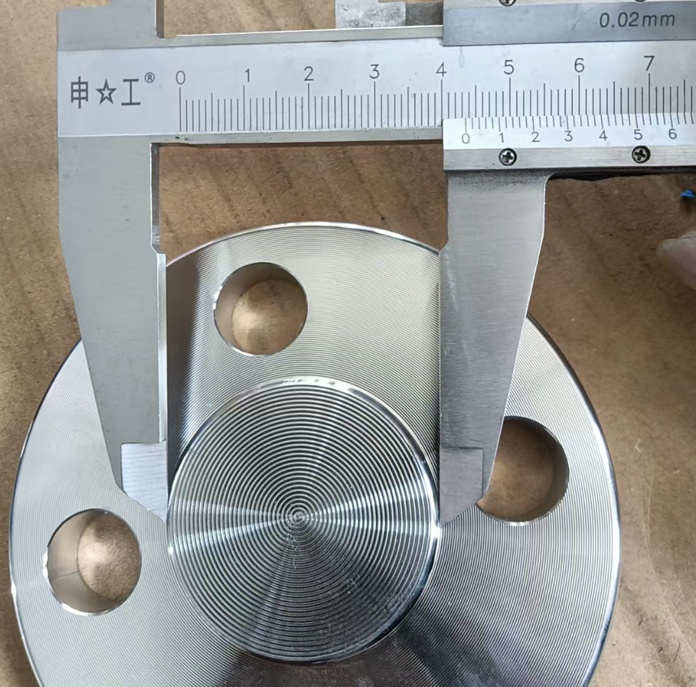

We are a trusted manufacturer, stockist, and exporter of ASTM A182 F44 flanges, made from high-alloy super austenitic stainless steel UNS S31254. Known for their exceptional corrosion resistance, especially in chloride-rich and seawater environments, F44 flanges are widely used in offshore, chemical processing, desalination, and marine industries.

What is ASTM A182 F44 ?

ASTM A182 F44 is a super austenitic stainless steel, also known as UNS S31254 or 254 SMO. This grade contains high levels of molybdenum (6%), nickel, and chromium, offering outstanding resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking.

With its high content of chromium (19.5-20.5%), nickel (17.5-18.5%), molybdenum (6.0-7.0%), and nitrogen (0.18-0.25%), this grade achieves a Pitting Resistance Equivalent (PREn) value of 42-44, ensuring exceptional resistance to pitting corrosion and crevice corrosion.

Equivalent grade of A182 F44/UNS S31254

ASTM A182 F44 Flanges are installed with ASTM A312 UNS S31254 Pipes and ASTM A403 WPS31254 Elbow,Pipe fittings.

A fully austenitic alloy with excellent corrosion resistance in a wide variety of aggressive, aqueous environments

| UNS | EN | ASTM | Other |

|---|---|---|---|

| S31254 | 1.4547 (X1CrNiMoN20-18-7) | F44 | 254 SMO |

ASTM A182 F44 flanges are forged components manufactured from high-alloy austenitic stainless steel known as UNS S31254 (6Mo stainless steel)

A182 F44 Chemical Composition (UNS S31254)

C | Cr | Cu | Fe | Mo | Mn | N | Ni | P | S | Si | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | – | 19.5 | 0.5 | Balance | 6.0 | – | 0.18 | 17.5 | – | – | – |

| Max | 0.02 | 20.5 | 1.0 | 6.5 | 1.0 | 0.22 | 18.5 | 0.030 | 0.010 | 0.8 |

UNS S31254 A182 F44 Mechanical Properties

| Mechanical (room temperature) | UTS | 0.2% Proof Strength | Elongation | Reduction in Area | Hardness |

| Min | Min | Min | Max | ||

| 650-850 Mpa | 300 Mpa | 35.00% | 50.00% | 260 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 8.0 kg/dm³ |

| Modulus of Elasticity at 20°C | 195 GPa |

| Mean Coefficient of Thermal Expansion (20-100°C) | 16.5 × 10⁻⁶ K⁻¹ |

| Thermal Conductivity at 20°C | 14 W·m⁻¹·K⁻¹ |

| Specific Thermal Capacity at 20°C | 500 J·kg⁻¹·K⁻¹ |

| Electrical Resistivity at 20°C | 0.85 Ω·mm²·m⁻¹ |

ASTM A182 F44 Flanges Specification

Material: ASTM A182 F44 / UNS S31254 (6Mo)

Type: ASTM A182 F44 Weld Neck Flange, ASTM A182 F44 Slip-On Flange , ASTM A182 F44 Blind Flange, Socket Weld, Threaded, Lap Joint, Orifice

Sizes: 1/2” to 60 ” or custom as per client specifications

Pressure Ratings: Class 150 to 2500, PN6 to PN400

Standards: ASME B16.5, B16.47, EN 1092-1, GOST, DIN

Why S31254 Flanges?

Superior Corrosion Resistance

F44 flanges offer excellent resistance to seawater, acidic media, and high chloride applications. They outperform standard stainless steels like 316L in environments where localized corrosion is a concern.

Applications of F44 materials

- Offshore platforms and subsea systems

- Desalination plants

- Chemical processing

- Pulp and paper industry

- Marine engineering

ASTM A182 F44 S31254 Flange Test Requirements

1. Chemical Composition Analysis

2. Mechanical Testing

3. Intergranular Corrosion Test (IGC)

- Standard: ASTM A262 Practice E

- When required: For applications in corrosive or welded conditions

- Purpose: To detect susceptibility to intergranular attack

4. Pitting Resistance Test (Optional / As Required)

- Standard: ASTM G48 (Method A or E)

5. Non-Destructive Testing (NDT)

- Visual Inspection – Mandatory for all flanges

- Liquid Penetrant Test (PT) – Used to detect surface cracks

- Ultrasonic Test (UT) – For critical flanges or large forgings

Certifications and Traceability

- EN 10204 3.1 or 3.2 Certificate

- Heat number traceable to test results

- Markings must include: ASTM A182 F44 (for 254 SMO), heat no., size, rating, manufacturer, etc.