S32750 Stud Bolts – Super Duplex Stainless Steel Fasteners for Extreme Environments

S32750 stud bolts, also known as Duplex 2507 or UNS S32750, are engineered to deliver exceptional performance in the most demanding industrial applications. With superior pitting resistance, outstanding mechanical properties, and excellent weldability, these Super Duplex Stainless Steel stud bolts are ideal for offshore, chemical processing, desalination, and oil & gas environments.

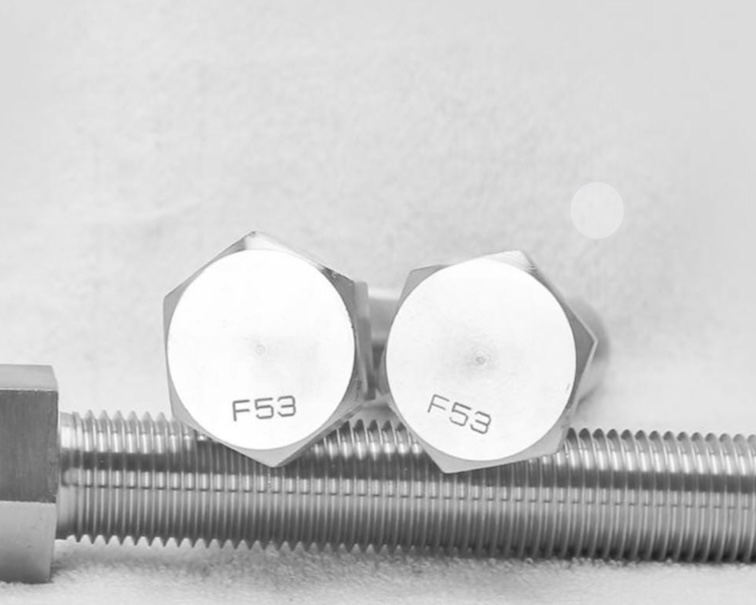

Super Duplex Stainless Steel S32750, also known as “2507” or “F53”, is a high-grade stainless steel alloy composed of 25% chromium, 7% nickel and 3.7% molybdenum. It has excellent corrosion resistance due to its high chromium and molybdenum ratios combined with its low carbon content.

Our S32750 stud bolts are produced from the round bar according to ASTM A479 Standard ,which is the Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels.

ASTM A479 UNS S32750 Specifications

- Material Grade: UNS S32750 (Super Duplex Stainless Steel)

- Standards: ASTM A479 / ASME SA479

- Equivalent Designations: WNR 1.4410, ASTM A182 F53

- Dimensions:

- Metric Sizes: M10 to M100

- Imperial Sizes: 3/8″ to 4″

- Lengths: Up to 4 meters

- Thread Types: UNC, UNF, 8UN, Metric Coarse & Fine (per ANSI B1.1 and B1.13M)

- Types Available: All-thread, double-end, tap-end, reduced shank, and flange stud bolts

Mechanical & Chemical Properties of UNS S32750 Stud bolt

UNS S32750 Chemical Composition

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdenum (Mo) | 3.0–5.0 |

| Nitrogen (N) | 0.24–0.32 |

| Carbon (C) | ≤ 0.030 |

| Manganese (Mn) | ≤ 1.20 |

| Silicon (Si) | ≤ 0.80 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.020 |

| Copper (Cu) | ≤ 0.50 |

UNS S32750 Stud bolt Mechanical Properties and Hardness requirement

| UNS Designation | Type | Heat Treatment Condition | Tensile Strength, min, ksi [MPa] | Yield Strength,<sup>A</sup> min, ksi [MPa] | Elongation in 2 in. [50 mm] or 4D, min, % | Reduction of Area, min, %<sup>C</sup> | Brinell Hardness, max |

| S32750 | 2 in. and under | annealed | 116 [800] | 80 [550] | 15 | — | 310 |

| over 2 in. | annealed | 110 [760] | 75 [515] | 15 | — | 310 |

Applications of UNS S32750 Stud Bolt

- Offshore Oil & Gas:

- Riser flanges, subsea manifolds, piping modules, and deck piping in harsh marine conditions

- Chemical & Petrochemical Processing:

- Heat exchangers, reactors, pressure vessels, and piping handling chlorides, acids, or caustics

- Desalination Plants:

- Brine handling pumps, membrane modules, and brine flash evaporators exposed to high-chloride feedwater

- Marine & Shipbuilding:

- Sea valves, seawater cooling systems, ballast piping, and desalination skids

- Power Generation:

- Flue-gas desulfurization (FGD) systems, cooling water headers, and condensate transfer lines

Why Choose Our S32750 Stud Bolts?

- Guaranteed Grade & Traceability

- Mill Test Certificate (MTC) conforming to EN 10204 3.1/3.2, with complete heat-number traceability.

- Positive Material Identification (PMI) to verify UNS S32750 before shipment

- Superior Corrosion & Mechanical Performance

- PREN ≥ 40 for long-term resistance against pitting and crevice corrosion.

- Duplex microstructure offers a balanced combination of high yield strength, fatigue resistance, and toughness.

- Custom Sizing & Tight Tolerances

- Standard sizes from 1/2″ – 4″ (UNC/UNF) or M12 – M100 (metric), with custom lengths up to 1 m.

- Thread accuracy to Class 2A/2B (imperial) or 6g/6H (metric) ensures precise fit in critical flanged assemblies.

- Industry-Compliant Testing & Certification

- Mechanical testing: Tensile, yield, elongation, hardness, and Charpy impact per ASTM A370.

- Intergranular corrosion (IGC) testing per ASTM A262.

- NACE MR0175/MR0103 certification available for sour-service applications.

- Packaging & Delivery

- Sea-worthy Packaging and promot shipment.

Ordering Information

When specifying ASTM A479 UNS S32750 Stud Bolts, please provide:

- Size & Length: e.g., M20 × 150mm or ¾″ × 6″

- Thread Type: UNC, UNF, Metric Coarse/Fine

- Type: All-thread, double-end, tap-end, etc.

- Standards Compliance: ASTM A479 / ASME SA479

- Testing Requirements: e.g., MTC per EN 10204 3.1/ 3.2

- Surface Finish: Mill finish, PTFE coated