STM A312 TP310S Stainless Steel Pipes Manufacturer & Supplier

We are a professional manufacturer and exporter of ASTM A312 TP310S seamless stainless steel pipes, offering premium quality high-temperature piping solutions for the petrochemical, furnace, heat exchanger, and refinery industries. TP310S is Known for its excellent oxidation resistance, high-temperature strength, and corrosion resistance, 310S (UNS S31008) is a low-carbon austenitic stainless steel ideal for elevated temperature applications.

What is ASTM A312 TP310S?

TP310S Pipe made according to ASTM A312 standard.

ASTM A312 is a specification for seamless and welded austenitic stainless steel pipes that perform well in high temperature and corrosive environments.

Product Specifications – ASTM A312 TP310S Pipes

| Specification | Details |

|---|---|

| Grade | TP310S (UNS S31008) |

| Standard | ASTM A312 / ASME SA312 |

| Type | Seamless |

| Size Range | ½” NB to 24″ NB (DN15–DN600) |

| Wall Thickness | SCH 10S, 40S, 80S, XXS, Custom |

| Length | Single Random, Double Random, Cut-to-Length |

Mechanical Property of ASTM A312 TP310S Pipe.

| SUS | Tensile Strength minimum (MPa) | Yield Strength 0.2% Proof minimum (MPa) | Elongation minimum (% in 50mm) | Hardness | |

| Rockwell B (HR B) maximum | Brinell (HB) maximum | ||||

| 310S | 515 | 205 | 40 | 95 | 217 |

ASTM A312 TP310s Pipe Chemical Material Composition

| ASTM A312 | Si | P | C | Mn | S | Cr | Mo | Ni | N | |

| 310s | min. | – | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 1.50 | 0.045 | 0.25 | 2.0 | 0.030 | 26.0 | 22.0 | – | ||

Equivalent Grades for Stainless Steel TP310S

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310S | S31008 | 310S16 | – | 1.4845 | X8CrNi25-21 | 2361 | SUS 310S |

Features of ASTM A312 TP310S Seamless Pipes

- Excellent high-temperature oxidation resistance (up to 1100°C)

- Low carbon improves weldability and reduces carbide precipitation

- Good corrosion resistance in oxidizing and carburizing environments

- Suitable for cyclic heating conditions

- Available in custom lengths and wall thicknesses

Heat Treatment Requirements

- 310S Seamless Pipes shall be furnished in the solution-annealed condition unless otherwise agreed.

Typical Heat Treatment for TP310S:

- Solution Annealing Temperature: 1040–1150°C (1900–2100°F)

- Cooling: Rapid cooling in water or air (depending on thickness) to prevent sensitization.

Testing Requirements (As per ASTM A312)

| Test Type | Requirement |

|---|---|

| Tensile Test | Required (One per lot of each heat + size) |

| Hardness Test | Required if tensile test not performed |

| Flattening Test | Required for seamless and welded pipes |

| Flare Test (Seamless only) | Required for pipe with OD < 4″ and SCH 10 or lighter |

| Hydrostatic Test | Mandatory unless NDE is substituted |

| Non-Destructive Examination | Permitted alternative to hydrostatic test |

| Visual Inspection | Surface shall be free from cracks and defects |

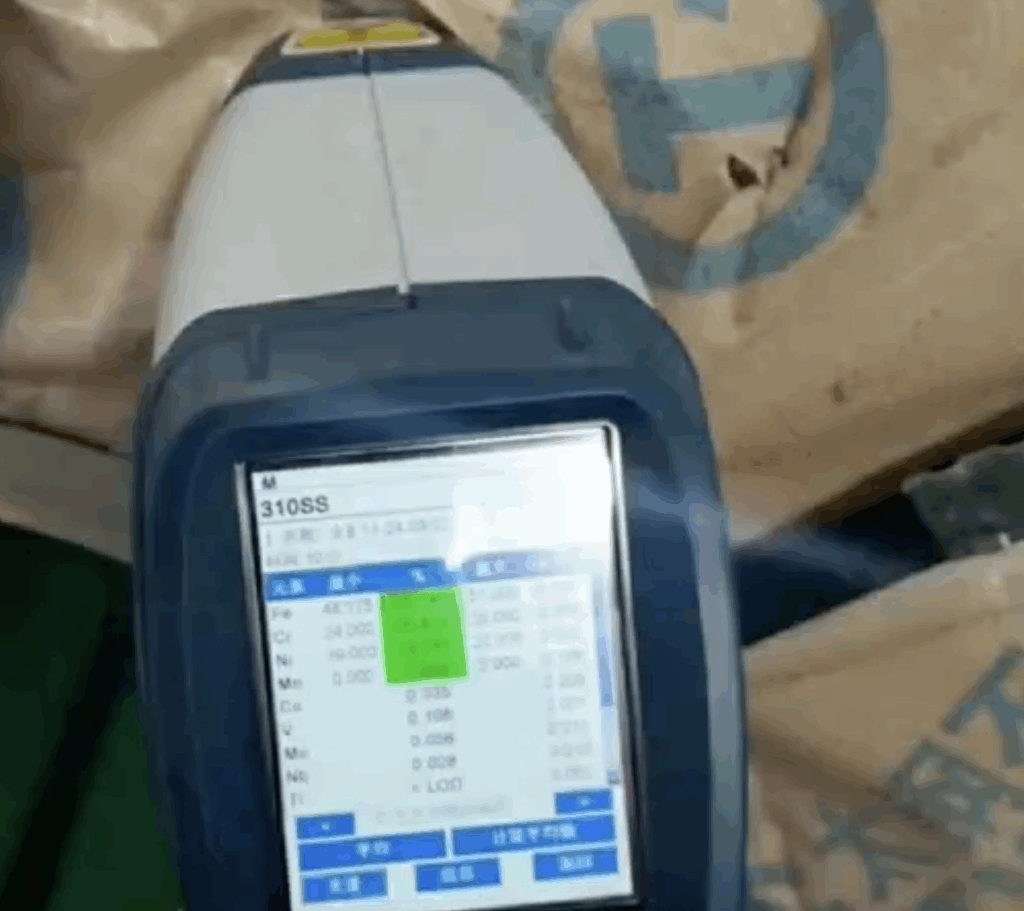

Optional Tests:

- PMI (Positive Material Identification)

- Intergranular Corrosion Test (IGC/ASTM A262)

- Ultrasonic Test (UT)

- Radiographic Test (RT) for weld integrity (for welded pipes)

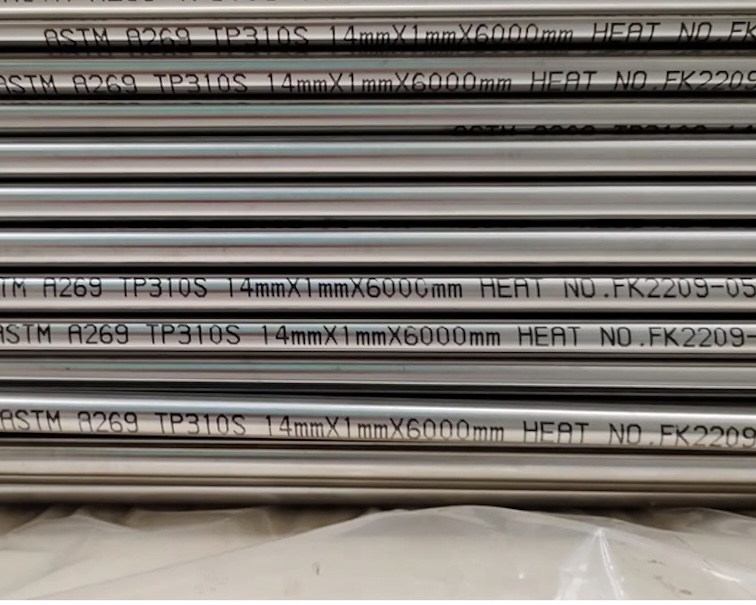

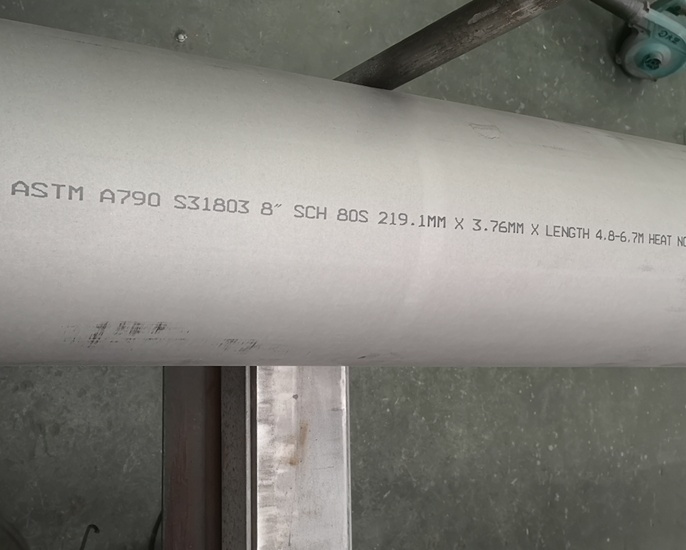

Marking Requirement

Each pipe shall be marked with:

- ASTM A312 / TP310S / Heat Number / Size / Schedule / Manufacturer’s name or logo

Mill Test Certificate (MTC)

Mill test certificate must conform to:

- EN 10204 3.1 (standard)

- EN 10204 3.2 (if third-party inspection is required)

Contact us now,and get the quote from the professional 310S stainless steel seamless pipe manufacturer.