In this article,you would find the chemicals,machanical ,heating,welding related with N08825 alloy 825 materials.

Basic Information on UNS N08825 (Alloy 825)

UNS N08825 — commonly known as Alloy 825 or Incoloy® 825 — is a nickel-iron-chromium alloy known for its excellent resistance to corrosion, especially in aggressive environments such as sulfuric acid, phosphoric acid, seawater, and chloride-containing systems.

| Property | Detail |

|---|---|

| UNS Number | N08825 |

| Standard Trade Name | Incoloy® 825 |

| Standards | ASTM B424 (plate/sheet), B564 forgings/N08825 flanges , B705 pipes), B423 (tubes), B425 bar/N08825 round bar |

Chemical Composition of Incoloy 825 (%)

| Element | Content |

|---|---|

| Nickel (Ni) | 38.0 – 46.0 |

| Iron (Fe) | Balance |

| Chromium (Cr) | 19.5 – 23.5 |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Titanium (Ti) | 0.6 – 1.2 |

| Carbon (C) | Max 0.05 |

| Manganese (Mn) | Max 1.0 |

| Silicon (Si) | Max 0.5 |

| Sulfur (S) | Max 0.03 |

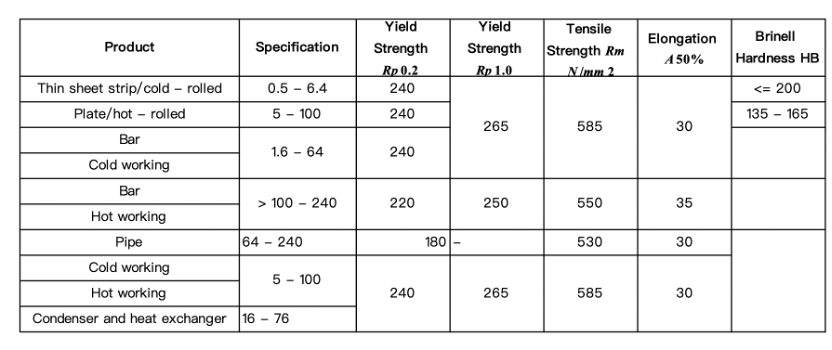

Mechanical Properties of Incoloy 825:

The properties listed in the following table apply to the specified products of Incoloy 825 alloy after soft annealing (stabilizing annealing). The special properties of non – standard size materials can be provided according to the requirements of specific application scenarios.

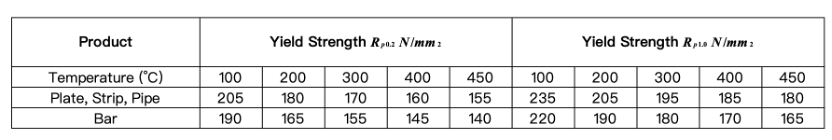

Elevated Temperature Mechanical Properties (Minimum Values)

Incoloy 825 Allowable Stress Values

The allowable stress values reaching 90% of the yield strength can be applied in application scenarios that permit a slightly larger amount of deformation. These stresses will cause permanent changes in the dimensions of the components, so they are not recommended for flanges and gasket connectors.

Microstructure of Incoloy 825

Incoloy 825 alloy has a stable face – centered cubic structure. Its chemical composition and appropriate heat treatment ensure that its corrosion resistance is not impaired by sensitization.

Corrosion Resistance of Incoloy 825

Incoloy 825 is a general – purpose engineering alloy with resistance to acid and alkali metal corrosion in both oxidizing and reducing environments.

- The high nickel content endows the alloy with effective resistance to stress corrosion cracking.

- It has good corrosion resistance in various acid solutions, such as sulfuric acid, phosphoric acid, nitric acid, and organic acids, as well as in alkali metals like sodium hydroxide and potassium hydroxide, and in salt solutions.

- Incoloy 825’s excellent comprehensive performance is demonstrated in nuclear fuel reprocessing dissolvers with diverse corrosive media, where sulfuric acid, nitric acid, and sodium hydroxide are all processed in the same equipment.

Application Range of Incoloy 825

Incoloy 825 is widely used in various industrial fields where the service temperature does not exceed 550°C.

Typical applications include:

- Heating tubes, vessels, baskets, chains, etc., for sulfuric acid pickling plants.

- Sea water – cooled heat exchangers, marine product pipeline systems, and pipelines in acidic gas environments.

- Heat exchangers, evaporators, washing and immersion tubes, etc., in phosphoric acid production.

- Air heat exchangers in petroleum refining.

- Food engineering applications.

- Chemical process applications.

- Flame – retardant alloys for high – pressure oxygen applications.

Processing and Heat Treatment of Incoloy 825

Incoloy 825 alloy is easy to process in general industrial processes.

Preheating of Incoloy 825

Temperature control is crucial to ensure that the alloy’s corrosion resistance is not impaired by sensitization. Workpieces must be surface – cleaned before and during heating to keep the surface clean.

If the heating environment contains sulfur, phosphorus, lead, or other low – melting – point metals, the Nicofer 6023/6023H alloy will become brittle. Impurities come from marked oils, muffs, lubricants, water, fuels, etc. The sulfur content of fuels should be low; for example, the impurity content of liquefied gas and natural gas should be less than 0.1%, and the sulfur content of city gas, when used as fuel, should be less than 0.25g/m³. A sulfur content of less than 0.5% is also acceptable.

Heat treatment is best carried out in a vacuum resistance furnace or under a protective inert gas atmosphere, so that precise temperature control can be achieved without impurity pollution. When the impurity content of the fuel gas is low, a fuel – fired heating furnace can also be considered, so that a neutral or slightly oxidizing atmosphere can be obtained. During heating, the atmosphere should be avoided from fluctuating between oxidizing and reducing, and the combustion flame should not directly impinge on the workpiece.

Hot Working of Incoloy 825

The suitable hot – working temperature for Incoloy 825 alloy is 1150 – 900°C, and the cooling method can be water quenching or rapid air cooling.

During hot working, the workpiece can be directly put into a preheated furnace. After the furnace reaches the set temperature, the holding time for the material is 60 minutes per 100mm thickness. After holding for the specified time, the workpiece should be immediately taken out of the furnace and processed within the specified temperature range. If the metal temperature drops below the minimum hot – working temperature, heating should be carried out again.

After hot working, timely annealing should be performed to ensure the best corrosion resistance and a suitable crystal structure.

Incoloy 825 Cold Working

Cold working should be carried out after solution treatment. The work hardening rate of Incoloy 825 is close to that of austenitic stainless steel, so the processing equipment should be adjusted accordingly.

Incoloy 825 Soft Annealing/Stabilizing

When the amount of cold working is relatively large, an intermediate annealing process should be carried out. When the final cold deformation is greater than 15%, a final stabilizing treatment is required.

- The temperature range for soft annealing or stabilizing treatment of Incoloy 825 is 920 – 980°C, and the most suitable temperature is 940 ± 10°C.

- For workpieces with a thickness greater than 1.5mm, it is recommended to use water quenching or rapid air cooling to obtain the maximum creep resistance.

- During any heat treatment process, attention should be paid to the matters mentioned above regarding keeping clean.

Incoloy 825 Grinding and Pickling

The oxide near the weld of Incoloy 825 workpieces is more difficult to remove than that of stainless steel and needs to be ground with fine sand belts or grinding wheels. To maintain the luster of the metal, great care should be taken during grinding.

Before pickling in a mixed acid of nitric acid and hydrofluoric acid, the oxide should also be removed with sandpaper or subjected to a salt bath pretreatment. The pickling time is especially critical.

Incoloy 825 Machining

Machining of Incoloy 825 should be carried out after solution treatment. The work hardening of the material should be considered. Different from austenitic stainless steel, lower surface cutting speed and feed rate need to be adopted.

Incoloy 825 Welding

When welding nickel – based alloys, the following regulations should be followed:

- Worksite

The worksite should be separated independently or be at a sufficient distance from the carbon steel processing area, kept as clean as possible, provided with partitions, and cross – ventilation between areas should be avoided. - Work Clothes and Auxiliary Items

Clean fine – textured gloves should be worn, and clean work clothes should be worn. - Tools and Machinery Equipment

Special tools for nickel – based alloys and nickel – chromium steels should be available. Steel wires should be made of stainless steel materials. Machinery equipment such as shears, punches, and rolling mills should be covered with felt, cardboard, or plastic paper to prevent iron – carbon metals from falling on the machine surface and causing corrosion of the processed materials.

Incoloy 825 Cleaning

Remove oil stains, dirt, and various marking imprints, and use acetone to clean the base metal and filler alloy (such as welding rods) in the welding area. Note that trichlorethylene TRI, perchloroethylene PER, and tetrachloride TETRA cannot be used.

Incoloy 825 Edge Preparation

Milling, planing, and other methods are preferred, and plasma cutting can also be carried out. If the latter is adopted, the cut edge (welding surface) must be ground smooth and flat, and precision grinding without overheating is allowed. The area of about 25mm width of the base metal on both sides of the weld should be ground until the bright metal is exposed.

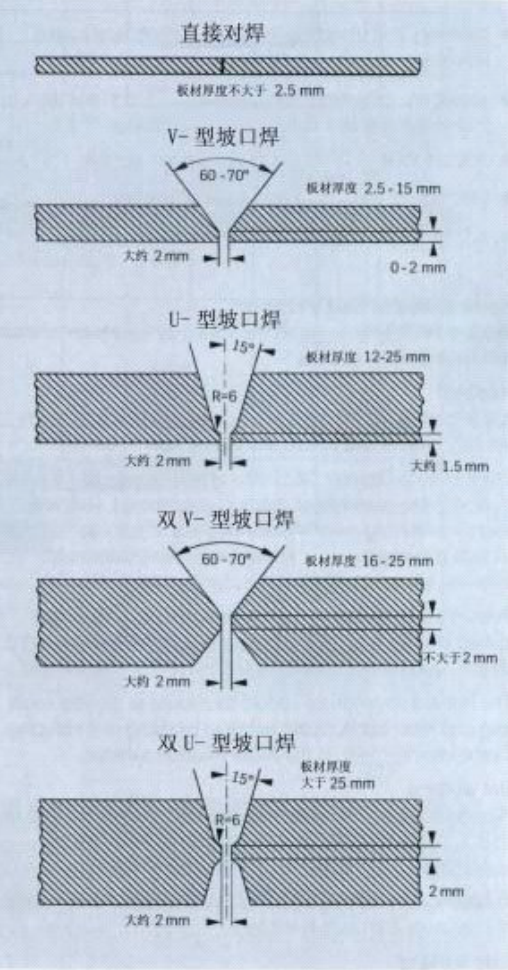

Incoloy 825 Weld Bevel Angle

Compared with carbon steel, the physical property characteristics of nickel – based alloys and special stainless steels are mainly low thermal conductivity and high expansion coefficient. These characteristics need to be considered when preparing the weld bevel, including widening the bottom gap (1 – 3mm). At the same time, due to the poor fluidity of molten metal, a larger bevel angle (60 – 70°) should be adopted during welding to offset the shrinkage of the material.

Incoloy 825 Arc Striking

Arc striking cannot be carried out on the workpiece surface; instead, arc striking should be carried out on the welding surface to prevent corrosion caused by arc striking points.

Incoloy 825 Welding Process

Incoloy 825 is suitable for welding with the same material or other metals using any traditional welding process, such as tungsten electrode inert gas shielded welding, plasma arc welding, manual sub – arc welding, metal – cored inert gas shielded welding, and molten – cored inert gas shielded welding. Among them, pulsed arc welding is the preferred solution. When using manual arc welding, it is recommended to use a protective gas mixed with multiple components such as (Ar + He + H₂ + CO₂).

- The welding of Incoloy 825 must be carried out in the annealed state, and stainless steel wire brushes should be used to clean stains, dust, and various marks. When welding the root of the weld, to obtain the best root weld quality, the operation must be very careful (argon gas 99.99%), so that no oxide is generated in the root weld after welding. The color generated in the welding heat – affected zone should be brushed off with a stainless steel brush when the weld zone is not cooled.

Incoloy 825 Filler Metal

For the gas shielded welding process, the following filler metals are recommended:

- Metal Welding Rods

- Nicofer S 6020 – FM625, Material No. 2.4831

- SG – NiCr21Mo9Nb, AWS A5.14: ERNiCrMo – 3

- Coated Welding Rods

- Material No. 2.4621

- EL – NiCr20Mo9Nb, AWS A5.11: ENiCrMo – 3

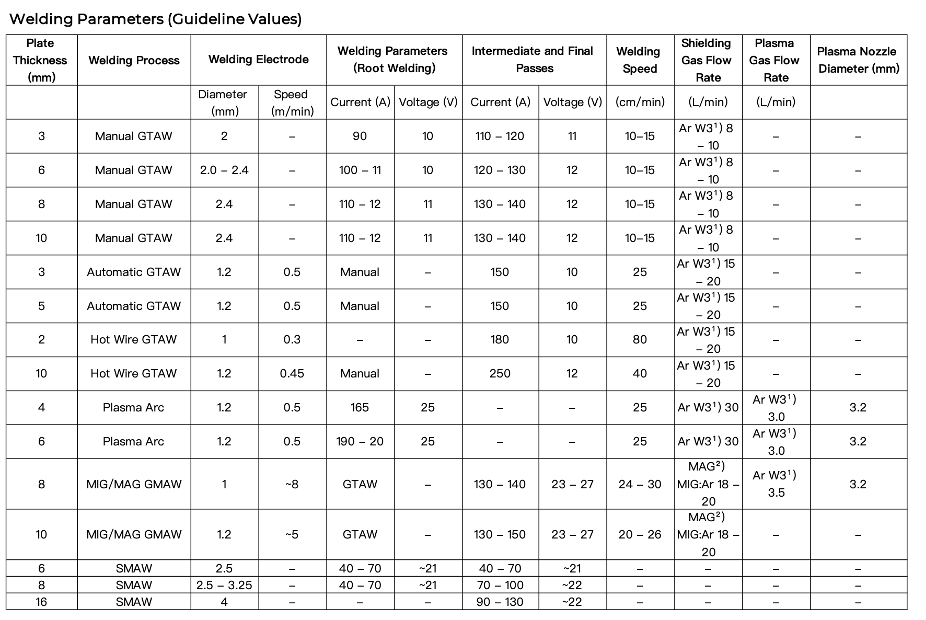

Incoloy 825 Welding Parameters and Influences (Heat Input)

The welding operation should be carried out under the low heat input specified in the heat input table, using the stacked bead weld technology, and the interlayer temperature should not exceed 120°C. The welding specifications must be followed.

The heat input Q is calculated as follows:Q=V×1000U×I×60(KJ/cm)

where:

- U: Arc voltage, Volt

- I: Welding current, Ampere

- V: Welding speed, cm/minute

Incoloy 825 Post – Welding Treatment (Pickling, Removal of Oxides and Heat Treatment)

After welding, stainless steel wire brushes should be used to remove oxides immediately, that is, brushing when the metal has not produced a weld – affected color, so that an ideal surface quality without pickling can be obtained.

Unless otherwise required or specified, pickling is usually the last process in welding. Please refer to the section on descaling and pickling.

No heat treatment is required before or after welding.

Welding End Preparation for Incoloy 825

Welding Guidance of Incoloy 825