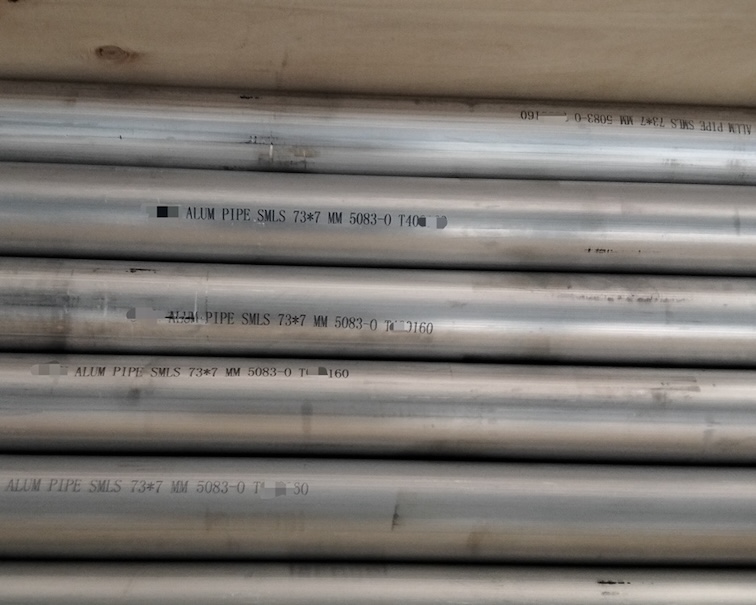

Aluminum 7075 T6 T651 Pipes Manufacturer & Supplier

We are a leading manufacturer and global supplier of Aluminum 7075 Pipes in T6 and T651 tempers, offering high-strength aluminum alloy tubing for demanding engineering, aerospace, defense, and structural applications.

Aluminum 7075 is one of the strongest aluminum alloys commercially available, combining exceptional mechanical strength with excellent fatigue resistance and outstanding machinability.

Our 7075 T6 and 7075 T651 pipes are produced to tight dimensional tolerances and meet international quality standards, making them suitable for high-load structural assemblies, aircraft components, sporting goods, transportation equipment, and precision engineering applications.

7075 T6 Aluminum Pipe

Aluminum Alloy 7075, in the T6 temper, is one of the strongest commercially available aluminum alloys. It is heat-treated to achieve superior mechanical properties, making it ideal for high-performance, load-bearing applications where weight reduction is critical.

7075 aluminium alloy (AA7075) also known as Al Zn5.5MgCu,is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It is one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts

Available Specifications

- Standards: ASTM B241 / ASTM B210 / AMS 4165

- Alloy: 7075

- Temper: T6 (Solution heat-treated and artificially aged)

- Form: Seamless or drawn pipe / tube

- OD Range: 6 mm to 250 mm

- Wall Thickness: 1 mm to 25 mm

- Length: Up to 6 meters (custom cut available)

Common Standards for 7075 Aluminum Pipe

| Standard | Description |

|---|---|

| ASTM B241 | Standard for aluminum and aluminum-alloy seamless pipe and tube |

| AMS 4169 | Aerospace Material Specification for 7075-T6 seamless tube |

Chemical Composition of Aluminum 7075 According to ASTM B241

| Alloy | Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Zinc | Titanium | Other Elements – Each | Other Elements – Total | Aluminum |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7075 | 0.40 | 0.50 | 1.2–2.0 | 0.30 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.20^M | 0.05 | 0.15 | remainder |

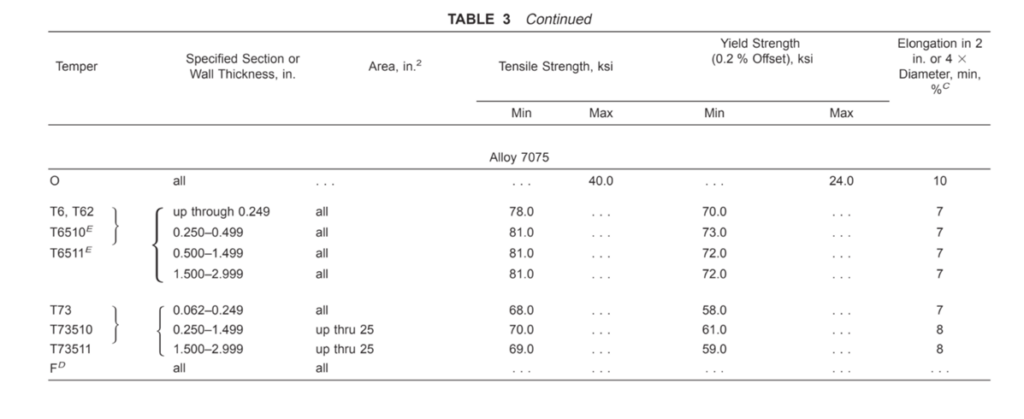

ASTM B241 7075 Pipe Mechanical Property

Sizes for 7075 Aluminum Pipe

- Outer Diameter (OD): 0.5” – 12” (12.7mm – 304.8mm)

- Wall Thickness: 0.035” – 1.000” (0.89mm – 25.4mm)

- Length: 6 ft, 12 ft, custom-cut

Heat Treatment for 7075 Aluminum

| Heat Treatment/Temper | Process Description | Effect on Properties |

|---|---|---|

| O (Annealed) | Heating to ~415°C (775°F), then slow cooling | Softest condition, best formability, low strength |

| T6 (Solution Heat-Treated + Artificial Aging) | 1. Solution heat treatment at ~480°C (900°F), then quenching in water 2. Aging at ~120°C (250°F) for 24 hours | Highest strength but lower stress-corrosion resistance |

| T73 (Overaged for Stress-Corrosion Resistance) | 1. Solution heat treatment at ~480°C (900°F) 2. Aging at ~108°C (225°F) for 8 hours, then 163°C (325°F) for 24 hours | Lower strength than T6, better corrosion resistance |

| T76 (Intermediate Between T6 & T73) | Similar to T73, but aged for a shorter time | Moderate strength, improved corrosion resistance |

| T651 (Stress-Relieved T6) | T6 treatment + minor stretching (1-3%) to relieve residual stresses | High strength, reduced internal stress for machining |

| T7351 (Stress-Relieved T73) | T73 treatment + minor stretching (1-3%) | High corrosion resistance with reduced stress |

Why Aluminum 7075

7075 is a cold-treated forged aluminum alloy that has a higher strength than regular steel. 7075 is one of the most powerful aluminum alloys for commercial applications. 7075 aluminum alloy has a compact structure and strong corrosion resistance, especially suitable for aviation and marine plates. It has general corrosion resistance, good mechanical properties, and anodic reaction. The fine grains result in better drilling performance in deep holes and improved tool wear resistance

Application of Aluminum 7075 Tube

Aerospace & Aviation

Automotive & Racing

Marine & Defense

Industrial & Structural Applications

Order Example

Product: Aluminum 7075 T651 Seamless Pipe

Size: 50 mm OD × 5 mm wall × 3000 mm

Temper: T651

Standard: ASTM B241

Finish: Mill Finish

Quantity: 500 meters

Certification: EN 10204 3.1

Contact Us for Your Aluminum 7075 T6 Pipe Needs

As a leading supplier of Aluminum 7075 T6 pipes, we provide custom lengths and precise specifications to meet your exact needs. Whether you need high-strength pipes for aerospace, automotive, or marine applications, we deliver premium-quality products designed for maximum performance and reliability.