ASME SA213 T22 tube seamless tube for Heat Exchanger

ASME SA213 T22 Alloy Steel Seamless Tubes | High-Temperature Boiler & Heat Exchanger

We are a leading manufacturer and exporter of ASME SA213 T22 alloy steel seamless tubes, Our T22 tubes can be used for requirements of power generation, petrochemical, and thermal processing industries.

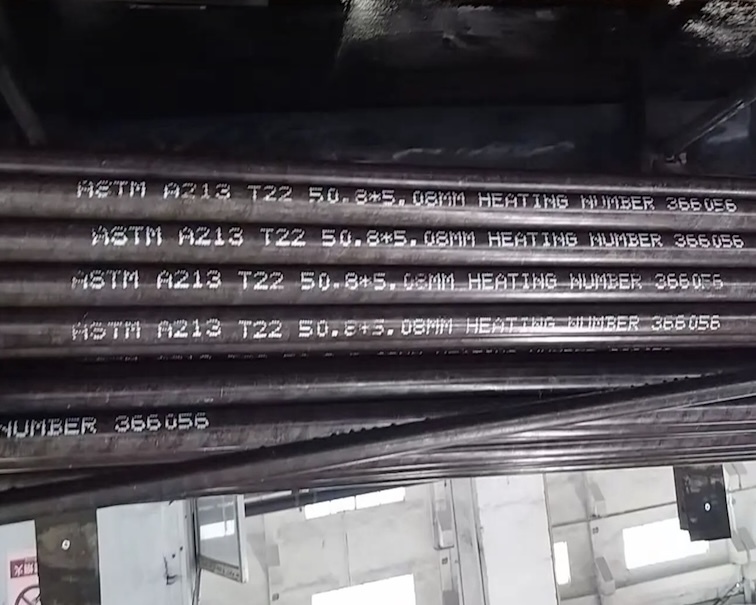

Seamless alloy steel tubes manufactured in accordance with ASTM A213/ASME SA213 standards, specifically designed for use in boilers, superheaters, reheaters, and heat exchangers.

Made from 2.25Cr-1Mo alloy steel, these tubes offer excellent resistance to high-temperature oxidation, pressure, and creep. They are widely used in power plants, refineries, and petrochemical industries.

T22 also known as a chromium-molybdenum alloy steel,

ASTM A213 is the Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASME A213 SPECIFICATION FOR SEAMLESS FERRITIC AND AUSTENITIC ALLOY – STEEL BOILER, SUPERHEATER, AND HEAT – EXCHANGER TUBES,which is the Identical with ASTM Specification A213/A213M except for the additional H Grade requirements in para. 6.2 and correction of UNS number for Grade T9 in Table 3.

ASME SA213 / ASTM A213 T22 Tube specification

- Standard: ASME SA213 / ASTM A213

- Grade: T22 (UNS K21590)

- Seamless construction for strength and integrity

- Excellent high-temperature and high-pressure performance

- Fully certified with EN 10204 3.1 or 3.2 Mill Test Certificates

Available Sizes:

- Outer Diameter: 6 mm to 127 mm

- Wall Thickness: 0.8 mm to 12 mm

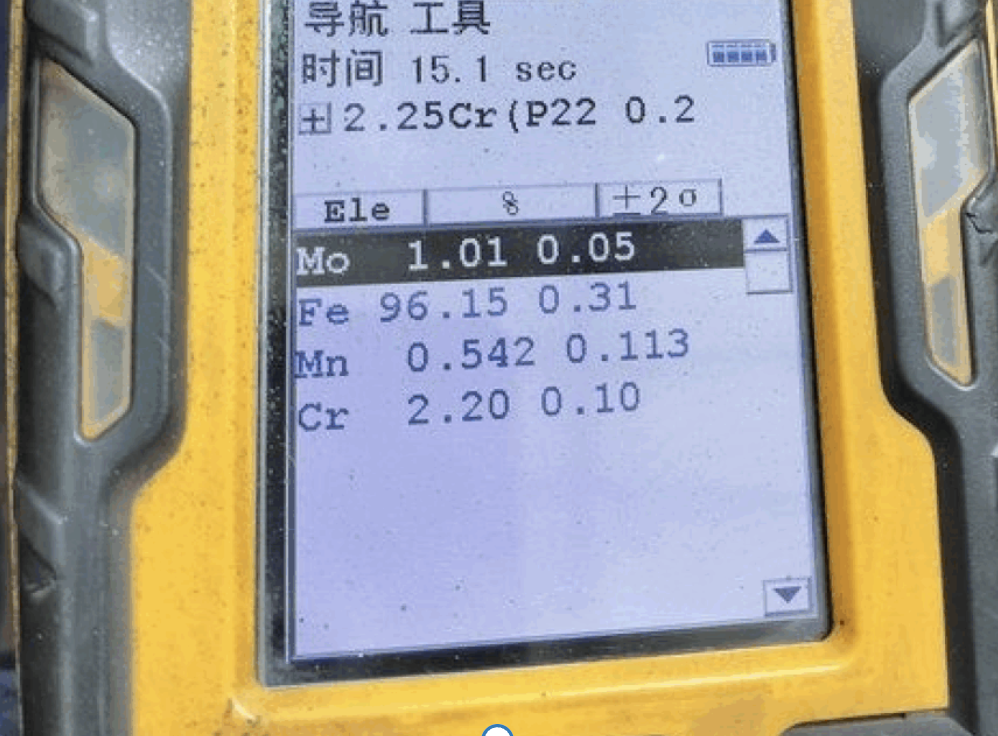

Chemical Composition Limits ASTM A213 T22

| Grade | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum |

| T22 | K21590 | 0.05 – 0.15 | 0.30 – 0.60 | 0.025 | 0.025 | 0.5 | – | 1.90 – 2.60 | 0.85 – 1.15 |

Tensile and Hardness Requirements of ASTM A213 T22

| Grade | UNS Designation | Tensile Strength, min, [MPa] | Yield Strength, min, [MPa] | Elongation in 2 in. or 4D, min, % | Hardness¹ | |

| Brinell/Vickers | Rockwell | |||||

| All other low alloy grades | – | 60 (415) | 30 (205) | 30 | 181 HRBW | 85 HRB |

| 170 HV | ||||||

Heat Treatment and Grain Size Requirements of ASTM A213 T22 tube

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solution Treatment Temperature, min or range, °F [°C] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range, °F [°C] | ASTM Grain Size No.² |

| T22 | K21590 | normalize and temper or full anneal or isothermal anneal. | – | – | 1250 (675) | – |

Average Wall Thickness Tolerance of ASTM A213 T22 Hot Formed Tubes

| TABLE 6 Permitted Variations in Average Wall Thickness for Hot Formed Tubes | ||

| Specified Outside Diameter, in. [mm] | Tolerance in % from specified wall thickness | Tolerance in % from specified wall thickness |

| Over | Under | |

| 73.0 [1853] and over to 10 in. [254 mm] | 20 | 12.5 |

| 10 in. [254 mm] and over, over 2.5% SYS (73.0) | 22.5 | 12.5 |

| (D = 5 %) | ||

| 10 in. [254 mm] and over, over 5.0% SYS (146.0) | 15 | 12.5 |

| (D = 10 %) | ||

| *T = specified wall thickness | ||

| D = specified outside diameter | ||

Number of Tubes in a Lot Heat Treated by the Continuous Process or by Direct Quench After Hot Forming

| Size of Tube | Size of Lot |

| 2 in. [50.8 mm] and over in outside diameter, over 0.200 in. [5.1 mm] in wall thickness | not more than 50 tubes |

| 2 in. [50.8 mm] and over in outside diameter, under 0.200 in. [5.1 mm] in wall thickness | not more than 75 tubes |

| Under 2 in. [50.8 mm] in outside diameter, over 0.200 in. [5.1 mm] in wall thickness | not more than 75 tubes |

| 1 in. [25.4 mm] or less in outside diameter | not more than 125 tubes |

Quality contro of ASME SA213 T22 alloy steel tubes

The test requirements for ASME SA213 T22 alloy steel tubes are defined in the ASME SA213 / ASTM A213 standard and are critical to ensure the tube’s quality, mechanical performance, and suitability for high-temperature applications like boilers, superheaters, reheaters, and heat exchangers

Standard Test Requirements for SA213 T22

1. Tensile Test (Mechanical Properties)

2. Hardness Test

3. Flattening Test

4. Flaring Test

- Only for tubes with OD < 50.8 mm (2 in).

- Purpose: Ensures the tube can expand without cracking.

- Flaring angle: Usually 60° as per standard.

5. Hydrostatic Test (Hydro Test)

- Mandatory: Yes.

- Purpose: To ensure the tube can withstand internal pressure without leakage.

- Pressure: Based on wall thickness and material; calculated per ASME B31.1/B31.3.

- Alternative: Nondestructive test (see below), but hydrotest is default.

6. Nondestructive Examination (Optional/Alternate)

- Eddy Current Test

- Ultrasonic Test

7. Mill Test Certificate (MTC)

- Certification Type: Typically per EN 10204 3.1 or 3.2 if third-party inspection is involved.