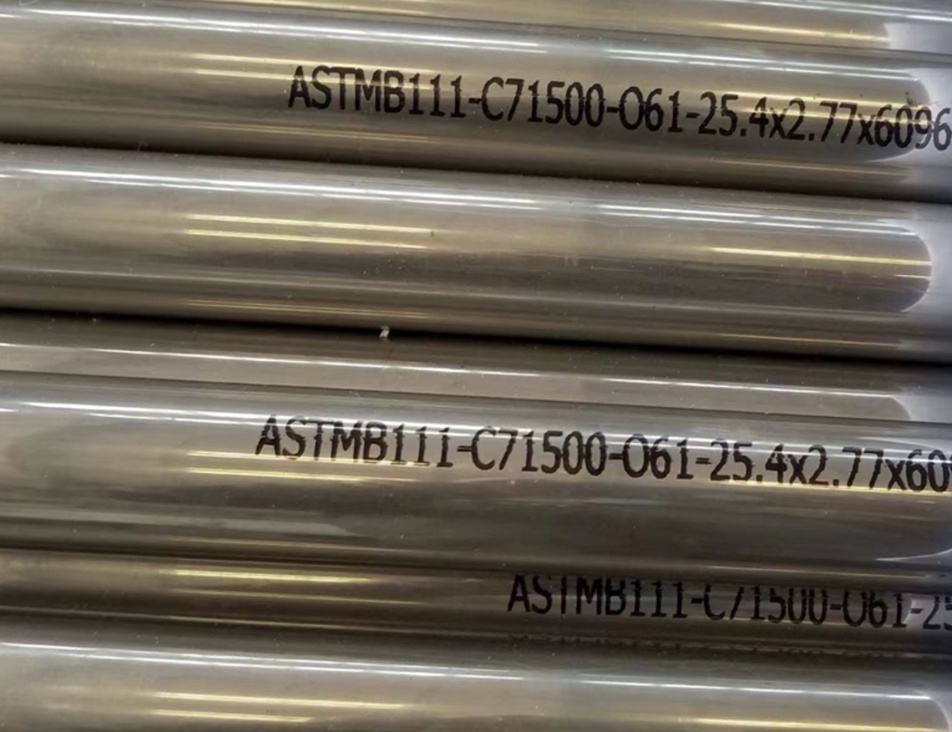

ASME SB111 / ASTM B111 C70600 C71500 Tubes

This specification establishes the requirements for seamless tube and ferrule stock of copper and various copper alloys up to 31/8 in. [80 mm] inclusive, in diameter, for use in surface condensers, evaporators, and heat exchangers

Our ASME SB111 / ASTM B111 copper-nickel tubes are available in:

- C70600 (CuNi 90/10) for ultimate seawater corrosion resistance

- C71500 (CuNi 70/30) for enhanced strength and erosion control

C70600 C71500 Equivalent grade of Different standards

| Grade | USA | U.K | Germany | Japan |

| China BG | ASTM | BS | DIN | JIS H |

| BFe10-1-1 | C70600 | CN102 | CuNi10Fe1Mn | C7060 |

| BFe30-1-1 | C71500 | CN107 | CuNi30Mn1Fe | C7150 |

Manufactured seamless,strict quality controls—100% eddy-current and hydraulic testing—to ensure leak-free performance in harsh chloride environments.

Chemical Composition of ASTM B111 C70600 Pipes

| C70600 Copper-Nickel Tube | ||

| Chemical composition (%) | Copper (Remainder) | Nominal 90% |

| Nickel (Ni) | 9.0~11.0% | |

| Lead (Pb) | 0.05% max | |

| Iron (Fe) | 1.0~1.8 | |

| Zinc (Zn) | 1.0% max | |

| Manganese (Mn) | 1.0% max | |

| Temper O61 | Tensile strength (MPa) | 275 min |

| Yield strength (MPa) | 105 min | |

| Temper H55 | Tensile strength (MPa) | 310 min |

| Yield strength (MPa) | 240 min | |

Chemical Composition of ASTM B111 C71500

| B111 C71500 | ||

| Chemical composition (%) | Copper(Cu) | remainder |

| Nickel (Ni) | 29.0~33.0 | |

| Manganese (Mn) | 1.0 max | |

| Lead (Pb) | 0.05 max | |

| Iron (Fe) | 0.40~1.0 | |

| Zinc (Zn) | 1.0 max | |

| Temper O61 | Tensile strength (MPa) | 360 min |

| Yield strength (MPa) | 125 min | |

Expansion Test

⚫ Tube specimens selected for test shall withstand the expansion shown in standard when expanded in accordance with Test Method B 153. The expanded tube shall show no cracking or rupture visible to the unaided eye.

⚫ Hard-drawn tubes not end annealed are not subject to this test. When tubes are specified end annealed, this test is required and shall be performed on the annealed ends of the sampled tubes.

⚫ Tubes for ferrule stock are not subject to the expansion test.

Flattening Test

⚫ Test Method—Each test specimen shall be flattened in a press at three (3) places along the length,each new place to be rotated on its axis approximately one third turn from the last flattened area. Each flattened area shall be at least 2 in. in length. A flattened test-specimen shall allow a micrometer caliper set at three (3) times the wall thickness to pass freely over the flattened area. The flattened areas of the test specimen shall be inspected for surface defects.

⚫ During inspection, the flattened areas of the test- specimen shall be free of defects, but blemishes of a nature that do not interfere with the intended application are acceptable.

⚫ Tubes for ferrule stock are not subject to flattening test.

Nondestructive Testing

Eddy-Current Test

—Each tube shall be passed through an eddy-current testing unit adjusted to provide information on the suitability of the tube for the intended application. Testing shall follow the procedures of Practice E 243.

Hydrostatic Test

Each tube shall stand, without showing evidence of leakage, an internal hydrostatic pressure sufficient to subject the material to a fiber stress of 7000 psi [48 MPa] as determined by the following equation for thin hollow cylinders under tension. The tube need not be tested at a hydrostatic pressure of over 1000 psi [7.0 MPa] unless so specified. P 5 2St/~D 2 0.8t! where: P = hydrostatic pressure, psi [MPa]; t = thickness of tube wall, in. [mm]; D = outside diameter of the tube, in. [mm]; and S = allowable stress of the material, psi [MPa].

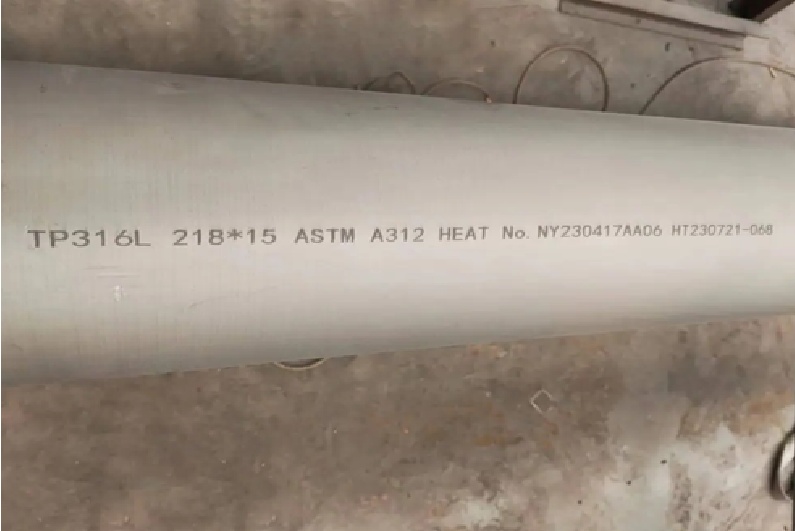

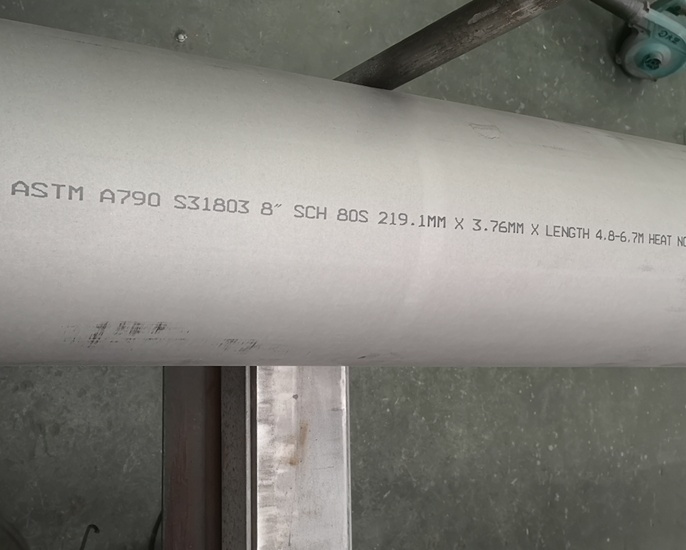

Certification & Traceability

- Mill Test Certificate: EN 10204 3.1/3.2

- Testing Records: Eddy-current, hydrostatic, PMI on request