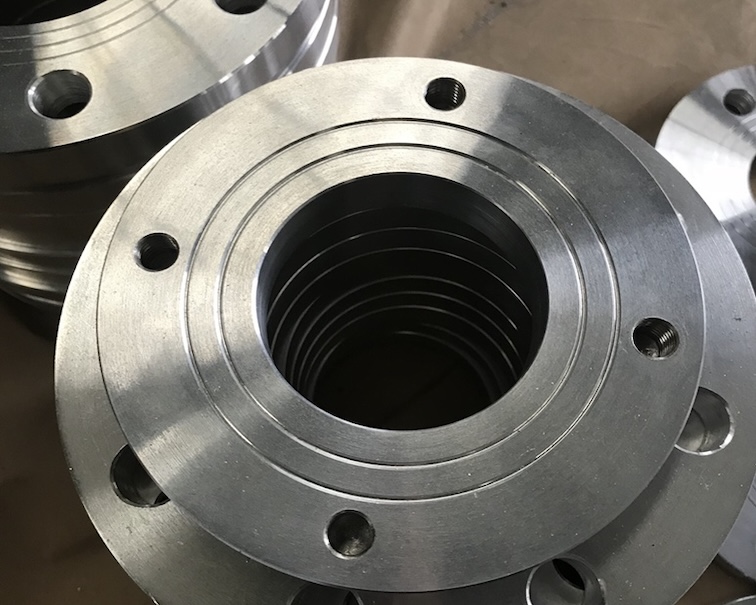

Spectacle Blind Flange ASME B16.48 Manafacturer in China

We are a professional Spectacle Blind Flange manufacturer in China, supplying high-quality products in full compliance with ASME B16.48 standards. Our spectacle blinds (also called figure-8 blinds) are widely used in piping systems to isolate or block pipeline flow during maintenance, testing, or system changes.

A spectacle blind flange,also knowns as Figure 8 flanges, is a dual-plate piping component—shaped like a pair of spectacles or figuire 8,—with one solid (blind) plate and one ring-shaped (spacer) plate joined together. It allows you to quickly switch a pipeline or valve between an open (flow) position and a closed (isolation) position without disassembling the flange connection.

ASTM A182 F53 UNS S32750 Spectacle Blind Flange (ASME B16.48)

- Material: ASTM A182 F53 (UNS S32750)Super duplex stainless steel

- Standard: ASME B16.48

- Pressure Classes: 150# – 2500#

- Nominal Sizes: ½″ – 24″

- Face Types: Raised Face (RF), Ring Type Joint (RTJ) Flat Face,(FF)

ASME B16.48 standard for Spectacle blind flange,Paddle Blank and Spacer

This Standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for operational line blanks in sizes NPS 1/2 through NPS 24 for installation between ASME B16.5 flanges in the 150, 300, 600, 900, 1500, and 2500 pressure classes.

astm a182 f53 material has carbon, manganese, phosphorus, silicon, 24% chromium, 6% nickel, 3% molybdenum and nickel and copper.

astm a182 f53 Chemical composition

| Grade | UNS Designation | Composition, % | ||||||||||

| ASTM A182 Grade F53 | S32750 | C | Mn | P | S | Si | Ni | Cr | Mo | CbB | Ti | Other Elements |

| 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | N 0.24-0.32 Cu 0.50 | ||||

Super duplex material ASTM A182 F53 can be used for Oil and gas industry equipment, Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems, Chemical process industries, heat exchangers, vessels, and piping,

Typical Applications of Super Duplex F53

- Oil & Gas: Wellhead Christmas trees, pipeline isolation, pressure testing.

- Petrochemical: Reactor feed isolation, heat exchanger maintenance.

- Power Generation: Turbine bypass circuits, condenser tube bundle testing.

- Marine & Offshore: Ballast systems, fire-water loops, chemical injection lines.

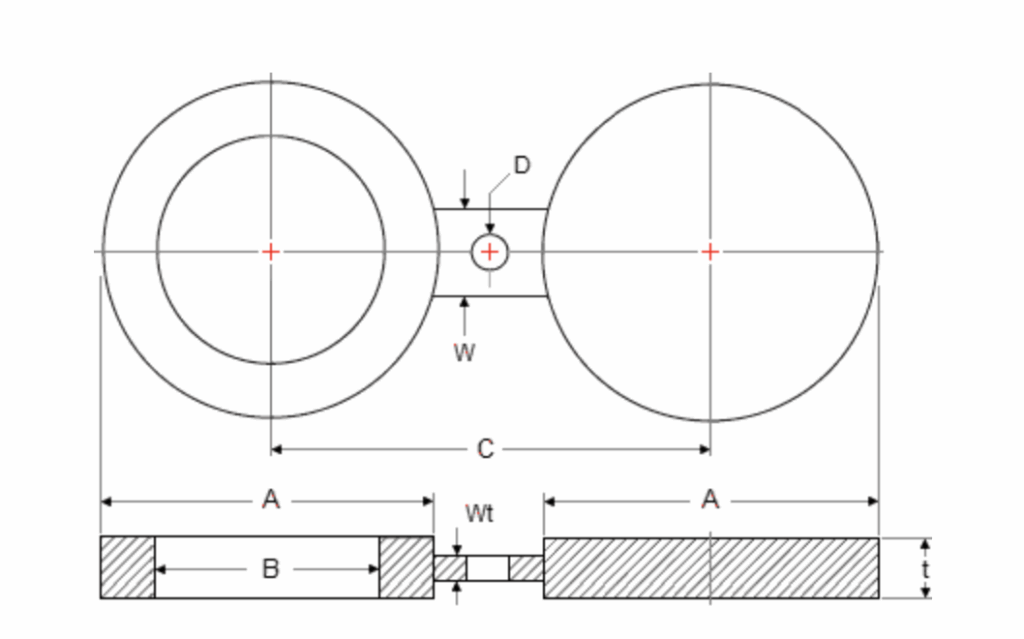

Dimensions Spectacle Blinds ASME B16.48

Pressure Class 150

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 45 | 16 | 60 | 3 | 38 |

| 3/4 | 54 | 21 | 70 | 3 | 38 |

| 1 | 64 | 27 | 80 | 3 | 38 |

| 1.1/4 | 73 | 42 | 90 | 6.4 | 38 |

| 1.1/2 | 83 | 48 | 100 | 6.4 | 38 |

| 2 | 102 | 61 | 120 | 6.4 | 51 |

| 2.1/2 | 107 | 73 | 140 | 6.4 | 51 |

| 3 | 133 | 89 | 150 | 6.4 | 64 |

| 3.1/2 | 159 | 102 | 175 | 9.7 | 64 |

| 4 | 172 | 114 | 190 | 9.7 | 64 |

| 5 | 194 | 141 | 215 | 9.7 | 76 |

| 6 | 219 | 168 | 240 | 12.7 | 76 |

| 8 | 276 | 219 | 300 | 12.7 | 76 |

| 10 | 337 | 273 | 360 | 15.7 | 102 |

| 12 | 406 | 324 | 430 | 19.1 | 102 |

| 14 | 448 | 356 | 475 | 19.1 | 108 |

| 16 | 511 | 406 | 460 | 22.4 | 108 |

| 18 | 546 | 457 | 580 | 25.4 | 114 |

| 20 | 603 | 508 | 635 | 28.4 | 121 |

| 24 | 714 | 610 | 750 | 31.8 | 140 |

Pressure Class 300

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 38 |

| 1.1/4 | 79 | 42 | 100 | 6.4 | 38 |

| 1.1/2 | 92 | 48 | 115 | 6.4 | 38 |

| 2 | 108 | 61 | 125 | 9.7 | 51 |

| 2.1/2 | 127 | 73 | 150 | 9.7 | 51 |

| 3 | 146 | 89 | 170 | 9.7 | 64 |

| 3.1/2 | 162 | 102 | 185 | 12.7 | 64 |

| 4 | 178 | 114 | 200 | 12.7 | 64 |

| 5 | 213 | 141 | 235 | 15.7 | 76 |

| 6 | 248 | 168 | 270 | 15.7 | 76 |

| 8 | 305 | 219 | 330 | 22.4 | 76 |

| 10 | 359 | 273 | 385 | 25.4 | 102 |

| 12 | 419 | 324 | 450 | 28.4 | 102 |

| 14 | 483 | 356 | 515 | 31.8 | 108 |

| 16 | 536 | 406 | 570 | 38.1 | 108 |

| 18 | 594 | 457 | 630 | 41.1 | 114 |

| 20 | 651 | 508 | 685 | 44.5 | 121 |

| 24 | 772 | 610 | 810 | 50.8 | 140 |

Pressure Class 600

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 57 |

| 1.1/4 | 79 | 37 | 100 | 9.7 | 57 |

| 1.1/2 | 92 | 43 | 115 | 9.7 | 67 |

| 2 | 108 | 55 | 125 | 9.7 | 57 |

| 2.1/2 | 127 | 67 | 150 | 12.7 | 67 |

| 3 | 146 | 83 | 170 | 12.7 | 67 |

| 3.1/2 | 159 | 96 | 185 | 15.7 | 76 |

| 4 | 191 | 108 | 215 | 15.7 | 76 |

| 5 | 238 | 135 | 265 | 19.1 | 86 |

| 6 | 264 | 162 | 290 | 22.4 | 86 |

| 8 | 318 | 212 | 350 | 28.4 | 95 |

| 10 | 397 | 265 | 430 | 35.1 | 105 |

| 12 | 454 | 315 | 490 | 41.1 | 105 |

| 14 | 489 | 346 | 525 | 44.5 | 114 |

| 16 | 562 | 397 | 605 | 50.8 | 124 |

| 18 | 610 | 448 | 655 | 53.8 | 133 |

| 20 | 679 | 497 | 725 | 63.5 | 133 |

| 24 | 787 | 597 | 840 | 73.2 | 152 |

Pressure Class 900

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 60 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 6.4 | 41 |

| 1 | 76 | 27 | 100 | 6.4 | 57 |

| 1.1/4 | 86 | 37 | 110 | 9.7 | 57 |

| 1.1/2 | 95 | 43 | 125 | 9.7 | 67 |

| 2 | 140 | 55 | 165 | 12.7 | 57 |

| 2.1/2 | 162 | 67 | 190 | 12.7 | 67 |

| 3 | 165 | 83 | 190 | 15.7 | 67 |

| 4 | 203 | 108 | 235 | 19.1 | 76 |

| 5 | 244 | 135 | 280 | 22.4 | 86 |

| 6 | 286 | 162 | 320 | 25.4 | 86 |

| 8 | 356 | 212 | 395 | 35.1 | 95 |

| 10 | 432 | 265 | 470 | 41.1 | 105 |

| 12 | 495 | 315 | 535 | 47.8 | 105 |

| 14 | 518 | 346 | 560 | 53.8 | 114 |

| 16 | 572 | 397 | 615 | 60.5 | 124 |

| 18 | 635 | 448 | 685 | 66.5 | 133 |

| 20 | 696 | 497 | 750 | 73.2 | 133 |

| 24 | 835 | 597 | 900 | 88.9 | 152 |

Pressure Class 1500

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 61 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 9.7 | 41 |

| 1 | 76 | 27 | 100 | 9.7 | 64 |

| 1.1/4 | 86 | 35 | 110 | 9.7 | 64 |

| 1.1/2 | 95 | 41 | 125 | 12.7 | 70 |

| 2 | 140 | 53 | 165 | 12.7 | 70 |

| 2.1/2 | 162 | 63 | 190 | 15.7 | 76 |

| 3 | 172 | 78 | 205 | 19.1 | 76 |

| 4 | 206 | 102 | 240 | 22.4 | 89 |

| 5 | 251 | 128 | 290 | 28.4 | 89 |

| 6 | 279 | 154 | 320 | 35.1 | 89 |

| 8 | 349 | 203 | 395 | 41.1 | 102 |

| 10 | 432 | 255 | 480 | 50.8 | 114 |

| 12 | 518 | 303 | 570 | 60.5 | 114 |

| 14 | 575 | 333 | 635 | 66.5 | 127 |

| 16 | 638 | 381 | 705 | 76.2 | 133 |

| 18 | 702 | 429 | 775 | 85.9 | 146 |

| 20 | 752 | 478 | 830 | 95.3 | 152 |

| 24 | 899 | 575 | 990 | 111.3 | 178 |

Pressure Class 2500

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

| 1/2 | 67 | 16 | 90 | 9.7 | 38 |

| 3/4 | 73 | 21 | 95 | 9.7 | 41 |

| 1 | 83 | 27 | 110 | 9.7 | 64 |

| 1.1/4 | 102 | 35 | 130 | 12.7 | 64 |

| 1.1/2 | 114 | 41 | 145 | 15.7 | 70 |

| 2 | 143 | 53 | 170 | 15.7 | 70 |

| 2.1/2 | 165 | 63 | 195 | 19.1 | 76 |

| 3 | 194 | 78 | 230 | 22.4 | 76 |

| 4 | 232 | 102 | 275 | 28.4 | 89 |

| 5 | 276 | 128 | 325 | 35.1 | 89 |

| 6 | 314 | 154 | 370 | 41.1 | 89 |

| 8 | 384 | 198 | 440 | 53.8 | 102 |

| 10 | 473 | 248 | 540 | 66.5 | 114 |

| 12 | 546 | 289 | 620 | 79.2 | 114 |

General notes..

- Dimensions are in millimeters unless otherwise indicated.

- D = Hole size (where required) should be the same as the flange bolt hole. In practice, these dimensions have been rounded round off upwards.

- Wt = Thickness of the web (or tie bar) should be 6 mm minimum, or equal to Thickness (t) if less than 6 mm.

- Spectacle Blinds should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges and piping involved.

- Spectacle Blinds ASME B16.48 may be used for installation between ASME B16.5 flanges

- Depending on a customer specification, some dimensions can be different from what on this page is defined.

Order Example

Product: ASTM A182 F53 Spectacle Blind Flange

Standard: ASME B16.48

Size: 8” Class 300 RF

Material: Super Duplex Stainless Steel UNS S32750

Quantity: 20 pcs

Certification: EN 10204 3.1 + NACE MR0175

We are professional manufacturer and exporter of ASTM A182 F53 (UNS S32750) Spectacle Blind Flanges, designed and produced according to ASME B16.48.

These flanges are made from Super Duplex Stainless Steel UNS S32750, offering exceptional strength, corrosion resistance, and toughness for use in high-pressure and corrosive industrial systems.

Our Spectacle Blind Flanges are commonly installed in oil & gas pipelines, offshore platforms, chemical processing plants, and desalination systems, allowing easy isolation and maintenance of pipeline sections.

Dimension of Spectacle Blind Flange ASME B16.48

DOWNLOAD THE DIMENSION OF SPECTACLE_BLIND_FLANGE-ASME B16.48 CL150 CL300

DOWNLOAD THE DIMENSION OF SPECTACLE_BLIND_FLANGE-ASME B16.48 CL600 CL900

DOWNLOAD THE DIMENSION OF SPECTACLE_BLIND_FLANGE-ASME B16.48 CL1500 CL2500