ASTM A182 F55 Flanges Manufacturer — Super Duplex Stainless Steel Flanges

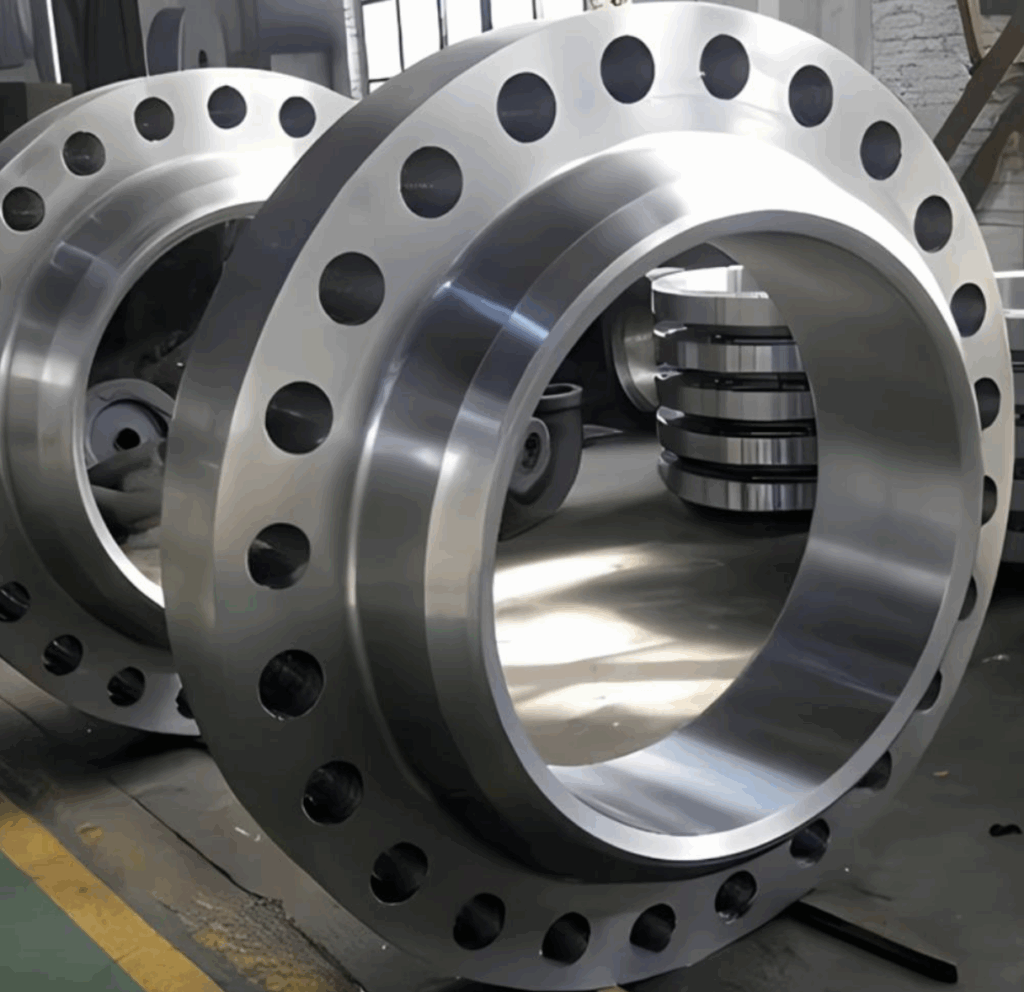

We are a leading manufacturer and stockist of ASTM A182 F55 flanges, offering a wide range of Super Duplex stainless steel flanges for critical applications in offshore, chemical, and marine industries. Our F55 flanges provide excellent corrosion resistance, high mechanical strength, and superior performance in harsh environments.

UNS S32760 is a super duplex stainless steel, with the chromium content of about 25%, that is also referred to as DIN 1.4501 and ASTM A182 F55 (when supplied as solid bars). it is also known as Zeron 100.

UNS S32760 is a super duplex stainless steel in American standards. Its composition is characterized by adding a small amount of W and Cu on the basis of high Cr, Mo, and N. This not only improves the casting performance , reduces the content of the precious metal Mo, and enhances the steel’s resistance to chloride ion pitting. The minimum guaranteed value of the pitting resistance equivalent number (PRE) is 40. Moreover, it has good resistance to pitting corrosion, crevice corrosion, and intergranular corrosion. It is mainly applied in corrosive environments in fields such as petroleum, natural gas, chemical industry, and shipping. Thus, it becomes an ideal material for various corrosion – resistant industrial application fields

Our A182 F55 Flanges are made from high quality UNS S32760 round bar.

Product Specification – ASTM A182 F55 Flanges

- Material Grade: ASTM A182 F55

- UNS Number: S32760

- WNR: 1.4501

- Standard: ASTM A182 / ASME SA182

- Type: Forged flanges

- Form: A182 F55 Weld Neck Flange, ASTM A182 F55 Blind Flanges, Slip-On, Socket Weld, Threaded, Lap Joint, Long Weld Neck

- Size Range: ½” to 48” (DN15–DN1200)

- Pressure Class: Class 150 to 2500 / PN6 to PN400

- Standard:ASME B16.5,B16.47,EN 1092-1

- Face Type: RF (Raised Face), RTJ (Ring Type Joint), FF (Flat Face)

- Delivery Condition: Solution Annealed & Pickled

1. Chemical Composition of ASTM A182 F55 Flanges

| Grade/Identification Symbol | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum | Niobium^B | Titanium | Other Elements |

| F 55 | S32760 | 0.03 | 1 | 0.03 | 0.01 | 1 | 6.0 – 8.0 | 24.0 – 26.0 | 3.0 – 4.0 | … | … | N 0.20 – 0.30 |

| Cu 0.50 – 1.00 | ||||||||||||

| W 0.50 – 1.00^D |

2. Tensile and Hardness Requirements^A

| Grade Symbol | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa]^B | Elongation in 2 in. [50 mm] or 4D, min, % | Reduction of Area, min, % | Brinell Hardness Number, HBW, unless otherwise indicated |

|---|---|---|---|---|---|

| F 55 | 109 – 130 [750 – 895] | 80 [550] | 25 | 45 |

3,Mechanical Properties of A182 F55

| Grade | Heat Treat Type | Austenitizing/Solution Heat Treatment Temperature, Minimum or Range, °F [°C]^A | Cooling Media | Quenching Cool Below °F [°C] | Tempering Temperature, Minimum or Range, °F [°C] |

|---|---|---|---|---|---|

| F 55 | solution treat and quench | 2010 – 2085 [1100 – 1140] | liquid | 500 [260] | B |

What to know the difference between ASTM A182 F53 and A182 F55?

Why Choose our ASTM A182 F55 Flanges?

- In-house forging, machining, and heat treatment facilities

- ISO 9001:2015 certified quality system

- 100% PMI, UT, and dimensional inspection

- EN 10204 3.1 / 3.2 Mill Test Certificates

- Fast delivery and global exporting capabilities