ASTM A312 UNS S31254 Pipes Manufacturer

We are a leading manufacturer, stockist, and exporter of ASTM A312 UNS S31254 Seamless Stainless Steel Pipes, also known as 6Mo Super Austenitic Stainless Steel Pipes.

These pipes are designed for high-corrosion resistance and excellent strength in harsh chloride-containing environments such as seawater, offshore platforms, pulp and paper plants, and chemical processing units.

ASTM A312 UNS S31254 Pipes, also known as 254 SMO stainless steel pipes, which are widely used for aggressive industrial environments.

It is installed with A403 WP31254 Pipe Fittings, and A182 F44 Flanges,and forged fittings in the pipeline connection.

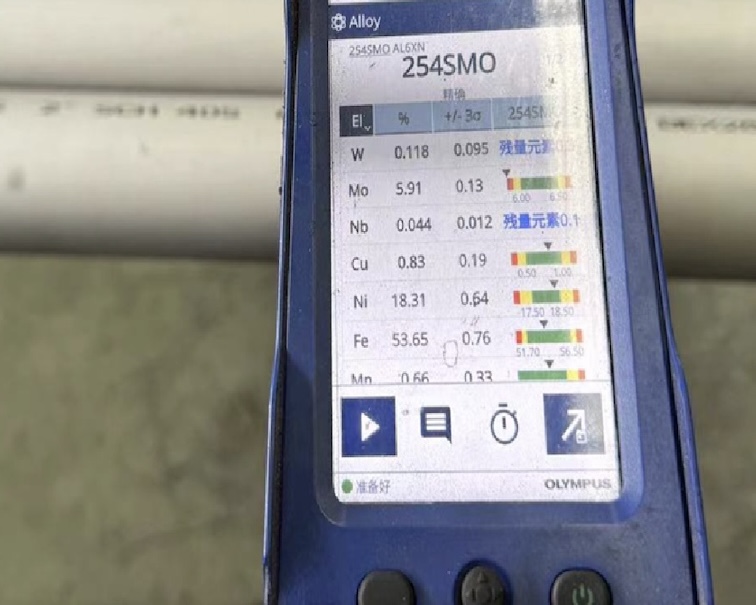

UNS S31254, Alloy 6Mo / WNR 1.4547 is or 254 SMO is a super – austenitic stainless steel (also known as UNS S31254), which is highly alloyed. It is developed by adding elements like molybdenum (Mo) and nitrogen (N) to enhance its corrosion resistance, especially in chloride – containing environments. Its main chemical components include approximately 20% chromium (Cr), 18% nickel (Ni), 6% molybdenum (Mo), and 0.2% nitrogen (N).

ASTM A312 is Standard Specification for Seamless and Welded Austenitic Stainless Steel Pipes

UNS S31254 Pipe Supply Scope

- Outer Diameter (OD): ½” to 24” or as per requirement

- Wall Thickness: SCH 10S, SCH 40S, SCH 80S and custom

- Length: Single random, double random, or cut-to-length

- Type: Seamless / Welded / ERW

UNS S31254 Composition

| Element | Min % | Max % |

|---|---|---|

| Carbon (C) | – | 0.020 |

| Chromium (Cr) | 19.50 | 20.50 |

| Nickel (Ni) | 17.50 | 18.50 |

| Molybdenum (Mo) | 6.00 | 7.00 |

| Nitrogen (N) | 0.18 | 0.25 |

| Copper (Cu) | 0.50 | 1.00 |

| Manganese (Mn) | – | 1.00 |

| Silicon (Si) | – | 0.70 |

UNS S31254 Pipes Mechanical Property

| Grade | UNS Designation | Tensile Strength, min ksi [MPa] | Yield Strength, min ksi [MPa] |

|---|---|---|---|

| t≤0.187in.[5.00mm] | S31254 | 98 [675] | 45 [310] |

| t>0.187in.[5.00mm] | S31254 | 95 [655] | 45 [310] |

A312 S31254 Pipe Heat treatment Requirement (Annealing)

ASTM A312 S31254, the heat – treating temperature is 2100 °F [1150 °C], and the cooling / testing requirements are denoted as “D”.

ASTM A312 S31254 Pipe Wall thickness tolerance

| NPS Designator | Tolerance, % from Nominal – Over | Tolerance, % from Nominal – Under |

|---|---|---|

| 81 to 221 incl., all t/D ratios | 20.0 | 12.5 |

| 3 to 18 incl., t/D up to 5 % incl. | 22.5 | 12.5 |

| 3 to 18 incl., t/D>5% | 15.0 | 12.5 |

| 20 and larger, welded, all t/D ratios | 17.5 | 12.5 |

| 20 and larger, seamless, t/D up to 5 % incl. | 22.5 | 12.5 |

| 20 and larger, seamless, t/D>5% | 15.0 | 12.5 |

Where:t = Nominal Wall ThicknessD = Ordered Outside Diameter

ASTM A312 UNS S31254 Pipe – Test Requirements

1. Chemical Composition Analysis

2. Mechanical Testing

Standard: ASTM A370

3. Intergranular Corrosion Test (IGC)

- Standard: ASTM A262 Practice E (when specified)

4. Non-Destructive Testing (NDT)

| Test Type | Description |

| Eddy Current Test | Detects surface/subsurface flaws (mandatory for seamless) |

| Ultrasonic Test (UT) | Used for welded pipes (per ASTM A999) |

| Visual Inspection | Mandatory for surface finish, welds, defects |

5. Hydrostatic Test

- Standard: ASTM A999 / A312

- Purpose: Verifies pressure containment of pipe

- Test Pressure: Typically 1.5x design pressure or as per client specs

- Frequency: Each pipe or 100% lot basis (as per order)

6. Positive Material Identification (PMI)

7. Mill Test Certificate (MTC)

- Format: EN 10204 3.1 or 3.2

- Must include: Chemical analysis, mechanical properties, heat number, traceability

Key Features of ASTM A312 S31254 (254 SMO) Pipes

- Superior corrosion resistance – ideal for seawater, brine, and chlorinated media

- Excellent pitting & crevice resistance – PREN > 42

- High mechanical strength – better than conventional austenitic steels

- High temperature and pressure tolerance

- Weldable and formable – suitable for fabrication and installation

- Standards compliance – ASTM A312, ASME SA312, EN 10216, NACE MR0175

International Specification Comparison chart of S31254

| Material | Round bars/Forgings | Plates/Sheets | Pipes/Tubes | ||

|---|---|---|---|---|---|

| Seamless | Welded | ||||

| JIS | |||||

| ASTM | S31254 | A182/A276/A479 | A240 | A312 | A312 |

| ASME | S31254 | SA182/SA276/SA479 | SA240 | SA312 | SA312 |

| DIN/EN | 1.4547 | ||||

S31254 is a super austenitic stainless steel containing 6% molybdenum. It is designed to have shock resistant toughness against chloride stress corrosion cracking, combined with good pitting and crevice corrosion resistance. Depending on the environment of use, this material is highly cost effective as a substitute to nickel or titanium alloys and is also excellent in machinability.

Related Products

- ASTM A182 F44 (UNS S31254) Flanges

- ASME SA403 WP S31254 Pipe Fittings

- 254SMO Round Bars

- ASTM B366 S31254 Buttweld Elbows

Order Example

Product: ASTM A312 UNS S31254 Seamless Pipe

Size: 4” SCH40 × 6000 mm

Standard: ASTM A312 / ASME SA312

End: Beveled End

Quantity: 1,200 meters

Certification: EN 10204 3.1 + NACE MR0175

⬇️ Download ASTM A312 UNS S31254 Stainless steel Pipes Now (PDF)