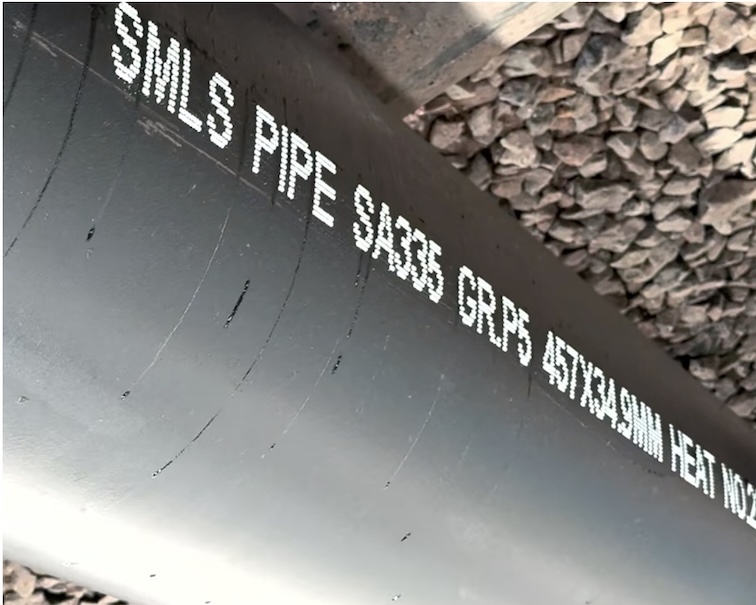

ASTM A335 P5 Seamless Steel Pipe Manufacturer

ASTM A335 P5 is a specification for seamless ferritic alloy-steel pipe intended for high-temperature service. It is widely used in industries such as power plants, oil refineries, petrochemical plants, and other sectors requiring materials capable of withstanding high pressures and temperatures.

ASTM A335 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

Download ASTM A335 2024 standard pdf (latest version)

| A335 Grade P5 5% Chrome; ½% Moly | SA335 Grade P5 5% Chrome; ½% Moly |

P,refers to the Pipe.

5,refers to the 5% Chromium.

P5 is a Chromium-molybdenum alloy steel,which contains 5% Chromium, 0.5% Molybdenum.

ASTM A335 P5 pipe is designed for high-temperature service, with a tensile strength of 415 MPa (60 ksi) and yield strength of 205 MPa (30 ksi). Its alloy composition, including chromium and molybdenum, enhances resistance to oxidation, corrosion, and thermal fatigue.

ASTM A335 P5 Pipes specification

Standard: ASTM A335 / ASME SA335

Grade: P5 (5% Chromium, 0.5% Molybdenum)

Type: Seamless alloy steel pipe

Applications: Boilers, heat exchangers, superheaters, pressure vessels

Size Range: NPS 1/8” to 24”, custom sizes available

Ends: Beveled End (BE), Plain End (PE),

Chemical Composition of ASTM A335 P5 Pipes

| Grade | UNS Designation | Carbon | Man-ganese | Phos-phorus, max | Sulfur, max | Silicon | Chromium | Molybde-num | Others |

| P5 | K41545 | 0.15 max | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 max | 4.00 – 6.00 | 0.45 – 0.65 | … |

| P5b | K51545 | 0.15 max | 0.30 – 0.60 | 0.025 | 0.025 | 1.00 – 2.00 | 4.00 – 6.00 | 0.45 – 0.65 | … |

| P5c | K41245 | 0.12 max | 0.30 – 0.60 | 0.025 | 0.025 | 0.50 max | 4.00 – 6.00 | 0.45 – 0.65 | … (B) |

Grade P5c shall have a titanium content of not less than 4 times the carbon content and not more than 0.70 %; or a niobium content of 8 to 10 times the carbon content.

Mechanical Properties of ASTM A335 P5 Seamless Pipe

| Grade | Mechanical property | ||

| Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | |

| P5 | ≥415 | ≥205 | ≥30 |

Heat treatment of ASTM A335 P5 Pipes

| Grade | Heat Treat Type | Normalizing Temperature, min or range °F [°C] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range °F [°C] |

| P5 | full or isothermal anneal or normalize and temper | … | … | … |

| 1250 [675] | ||||

| P5b | full or isothermal anneal or normalize and temper | … | … | … |

| 1250 [675] | ||||

| P5c | full or isothermal anneal or subcritical anneal | … | … | … |

| 1325–1375 [715–745] |

Permissible Variations in Outside Diameter According to ASTM A335

| NPS [DN] Designator | Over (in.) | Over (mm) | Under (in.) | Under (mm) |

| ⅛ to 1½ [6 to 40], incl. | ¹⁄₆₄ (0.015) | 0.40 | ¹⁄₆₄ (0.015) | 0.40 |

| Over 1½ to 4 [40 to 100], incl. | ¹⁄₃₂ (0.031) | 0.79 | ¹⁄₃₂ (0.031) | 0.79 |

| Over 4 to 8 [100 to 200], incl. | ¹⁄₁₆ (0.062) | 1.59 | ¹⁄₃₂ (0.031) | 0.79 |

| Over 8 to 12 [200 to 300], incl. | ³⁄₃₂ (0.093) | 2.38 | ¹⁄₃₂ (0.031) | 0.79 |

| Over 12 [300] | ± 1 % of the specified outside diameter | – | – | – |

TABLE 8 Permitted Variations in Wall Thickness According to ASTM A335

| NPS [DN] Designator | Tolerance, % from Specified – Over | Tolerance, % from Specified – Under |

| ⅛ to 2½ [6 to 65] incl., all t/D ratios⁽ᴬ⁾ | 20.0 | 12.5 |

| Above 2½ [65], t/D ≤ 5 %⁽ᴬ⁾ | 22.5 | 12.5 |

| Above 2½ [65], t/D > 5 %⁽ᴬ⁾ | 15.0 | 12.5 |

Test Requirements for ASTM A335 P5 Pipe

1. Chemical Composition Test

2. Mechanical Tests

| Test | Purpose | Requirement |

| Tensile Test | Determines yield and tensile strength | Performed on one pipe per lot |

| Hardness Test | Verifies material hardness | Optional, based on client/spec needs |

| Flattening Test | Assesses ductility and weld soundness | Especially on smaller diameters |

| Bend Test | Checks ductility and flexibility | May be substituted for flattening |

| Impact Test (Charpy V-Notch) | Optional for high-impact or low-temp service | Required by some clients/specs |

3. Hydrostatic Test

- Mandatory unless the pipe is tested with NDE (see below).

- Ensures the pipe can withstand internal pressure without leakage.

- Pressure level: Usually ≥ 1.5 times the design pressure.

4. Nondestructive Examination (NDE) (as alternative to hydro)

- Electric or ultrasonic testing per ASTM A999 or A335 for seamless pipes.

- Detects surface and subsurface defects like cracks, inclusions, or porosity.

5. Visual and Dimensional Inspection

6. Optional / Supplementary Tests (upon request):

- Positive Material Identification (PMI) – using XRF analyzers

- Grain size determination

- Third-party inspection (by SGS, BV, Lloyd’s, etc.)

- NACE MR0175/MR0103 compliance for sour service

Certification

- Mill Test Certificate (MTC) as per EN 10204 3.1 or 3.2

How to order A335/A335M Pipe P5

Pipe shall be ordered to nominal pipe size and schedule specified in ASME B36.10M.

Example: A335/A335M Pipe P5 NPS 12 Sch 40

| Parameter | Value |

|---|---|

| Specification Number | ASTM A335/A335M |

| Pipe | P |

| Grade | P-5 |

| NPS | 12 |

| Wall | 0.375 |