ASTM A453 Grade 660 Class B Stud bolt Fasteners Manufacturer

ASTM A453 Grade 660 Class B is engineered as one of the ideal material for high-temperature and high-pressure applications.

ASTM A453 Grade 660 B or Class B stud bolts are high-strength fasteners typically used in high-temperature and high-pressure environments such as power plants, petrochemical facilities, and nuclear applications.

ASTM A453 Standard Specification for High-Temperature Bolting, with Expansion Coefficients Comparable to Austenitic Stainless Steels.

This specification² covers five grades of bolting materials with twelve classes of yield strength ranging from 50 to 120 ksi [345 to 827 MPa] for use in high – temperature service for bolting components, such as bolts, screws, nuts, or studs, for pressure vessel and valve flanges.

See Specification ASTM A962/A962M for the definition of bolting.

Standard Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to the Creep Range

Download ASTM A453 standard pdf

Chemical Compostion of Grade 660 as per ASTM A453

| Element | Content, % (Grade 660, UNS S66286) | Product Analysis Variation, Over or Under, % |

| Carbon | 0.08 max | 0.01 over |

| Manganese | 2.00 max | 0.04 |

| Phosphorus | 0.040 max | 0.005 over |

| Sulfur | 0.030 max | 0.005 over |

| Silicon | 1.00 max | 0.05 |

| Nickel | 24.0–27.0 | 0.2 |

| Chromium | 13.5–16.0 | 0.2 |

| Molybdenum | 1.00–1.50 | 0.05 |

| Tungsten | … | … |

| Titanium | 1.90–2.35 | 0.05 |

| Columbiumⁿ | … | … |

| Aluminum | 0.35 max | 0.05 over |

| Vanadium | 0.10–0.50 | 0.03 |

| Boron | 0.001–0.010 | 0.0004 under to 0.001 over |

| Copper | … | … |

There are 4 Classes for Grade 660 according to ASTM A453,each class has difference heat treatment temperature and methods.

and grade 660 Class B is with solution treatment 1800 ± 25 °F [980 ± 14 °C], hold 1 h min, and oil quench,then Hardening Treatment at 1425 ± 25 °F [775 ± 14 °C] hold 16 h, air cool, followed by 1200 ± 25 °F [650 ± 14 °C] hold 16 h, air cool.

Heat treatment condition for ASTM A453 grade 660 Cl B fasteners

| Grade Symbol | Class | Solution Treatment | Hardening Treatment |

| 660 | A | 1650 ± 25 °F [900 ± 14 °C], hold 2 h, min, and liquid quench | 1325 ± 25 °F [720 ± 14 °C], hold 16 h, air cool |

| 660 | B | 1800 ± 25 °F [980 ± 14 °C], hold 1 h, min, and liquid quench | 1325 ± 25 °F [720 ± 14 °C], hold 16 h, air cool |

| 660 | C | 1800 ± 25 °F [980 ± 14 °C], hold 1 h min, and oil quench | 1425 ± 25 °F [775 ± 14 °C] hold 16 h, air cool, followed by 1200 ± 25 °F [650 ± 14 °C] hold 16 h, air cool |

| 660 | D | 1650 ± 25 °F [900 ± 14 °C], hold 2 h min, and liquid quench or 1800 ± 25 °F [980 ± 14 °C], hold 1 h min, and liquid quench | 1325 ± 25 °F [720 ± 14 °C], hold 16 h, air cool If necessary to achieve properties, second age: 1200 ± 25 °F [650 ± 14 °C] hold 16 h, air cool |

ASTM A453 Grade 660 fasteners Tensile Strength Yield Strength,and Hardness.

Grade 660 A,B,C has the same mechinical properties as below table

| Grade | Class | Tensile Strength, min | Yield Strength (0.2 % Offset), min | Elongation in 4× Diam, min, % | Reduction of Area, min, % | Brinell Hardness Number | Approximate Rockwell Hardness, B and C | |||

| ksi | MPa | ksi | MPa | min | max | |||||

| 660 | A, B, and C | 130 | 895 | 85 | 585 | 15 | 18 | 248–341 | 24 HRC | 37 HRC |

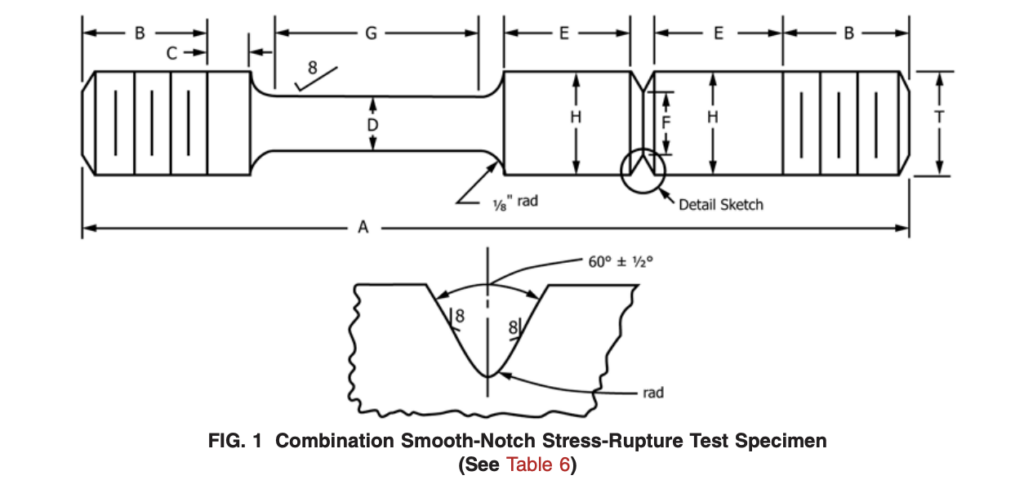

ASTM A453 Grade 660 fasteners Stress Rupture Requirement

| Grade | Class | Test Temperature, °F [°C] | Stress, min | Time to Rupture, min, hⁿ | Elongation, min, % | |

| ksi | MPa | |||||

| 660 | A, B, and C | 1200 [650] | 56 | 385 | 100 | 5 |

For bolts made of A453 Gr.660 material, the applicable temperature range is -29~525℃ in chemical industry standards, while it is -198~538℃ in ASME standards.

ASTM A453 Grade 660 Equivalent Materials

| Standard/Code | Equivalent Material | Notes |

|---|---|---|

| UNS Number | S66286 | Exact equivalent; base alloy number for A453 Gr.660 |

| Alloy Name | Inconel A-286 | Trademark name by Special Metals; commonly used |

| EN/DIN (Europe) | 1.4980 | German designation (X6NiCrTiMoVB25-15-2) |

A453 Gr.660 is a heat-resistant stainless steel with a coefficient of thermal expansion similar to that of austenitic stainless steel. In the 2012 edition of ASME B31.3 and earlier versions, A453 Gr.660 bolts were only suitable for working conditions of -30~538℃. However, in the 2016 edition of ASME B31.3 and subsequent versions, these bolts are specified to be applicable for -198~538℃. A domestic valve manufacturer has already applied this material’s bolts to LNG valves. It is recommended to confirm the applicability of the working conditions with the supplier before procurement.