ASTM A453 Grade 660 round bars are with superior strength, heat resistance, and reliability in extreme environments. Made from precipitation-hardened austenitic stainless steel (UNS S66286), this alloy is ideal for high-pressure bolting applications in industries such as power generation, petrochemical, aerospace, and oil & gas.

A453 Grade 660 round bar can be used to produce ASTM A453 Grade 660 Stud bolt

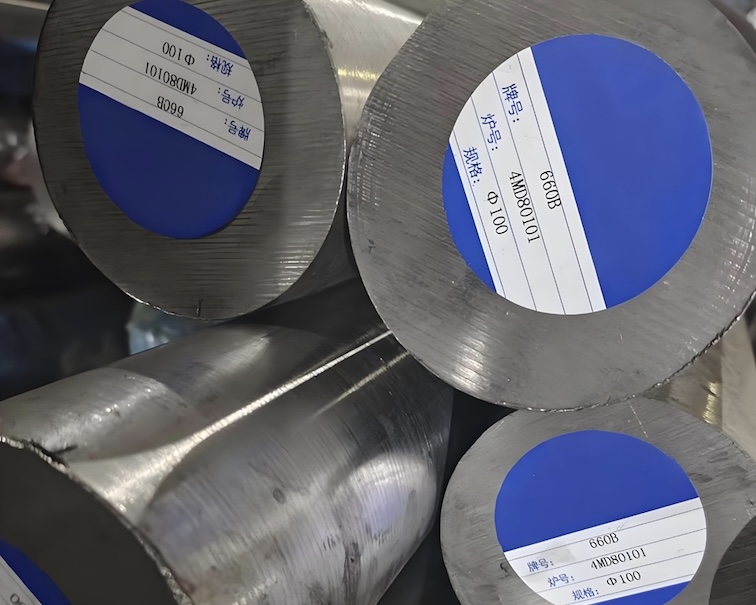

ASTM A453 Grade 660 Round Bar specification

- Material Grade: ASTM A453 Grade 660 (Class A, B, C, D)

- Standard: ASTM A453 / ASME SA453

- Type: Hot Rolled / Annealed / Heat Treated Round Bars

- Size Range: 10 mm to 200 mm diameter (custom sizes available)

- Length: Up to 6000 mm or as per customer requirement

- Heat Treatment: Solution treated + age hardened for high temperature service

Grade 660 Round Bar are manufactured according to ASTM A453

ASTM A453 is the Standard Specification for High-Temperature Bolting, with Expansion Coefficients Comparable to Austenitic Stainless Steels

This specification covers standards for Grade 660 (Class A, B, C, and D) , Bolting materials in this specification covers rolled, forged, or hot-extruded bars, and also bolts, nuts, screws, washers, studs, and stud bolts. Materials shall adhere to specified contents of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, tungsten, titanium, columbium, aluminum, vanadium, boron, and copper. Materials shall be subjected to tension, stress-rupture, and hardness tests. Materials shall conform to yield strength, tensile strength, elongation, reduction of area, Brinell hardness, and Rockwell hardness requirements. Hardening and solution treatment requirements for each material class are also given.

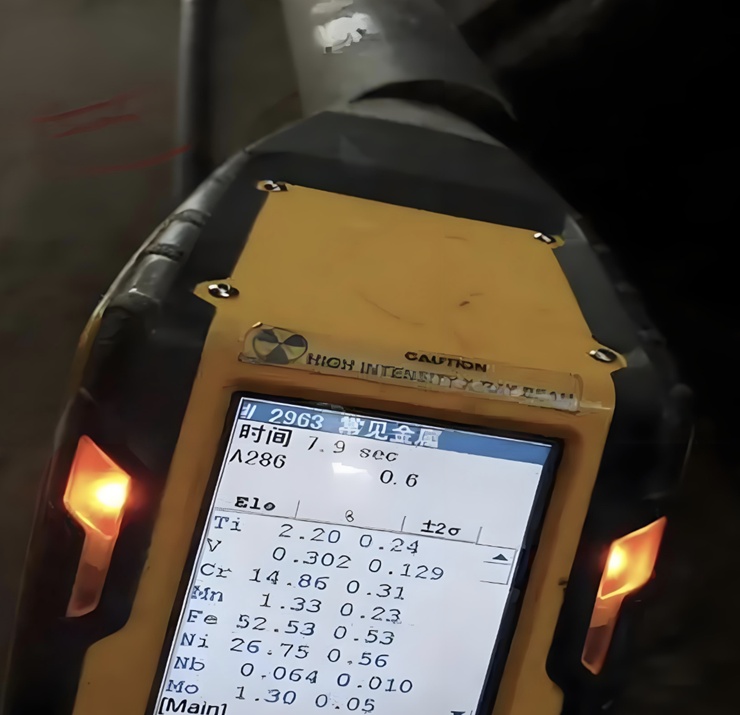

ASTM A453 Grade 660 Chemical Composition Limits

| ASTM A453 Grade 660 Chemical Composition Limits | ||||||||||||||

| Weight% | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | V | Al | B | Co | Cu |

| ASTM A453 GR.660A | 0.08 max | 2 max | 0.025 max | 0.025 max | 1 max | 13.5-16 | 24-27 | 1-1.5 | 1.9-2.35 | 0.10-0.50 | 0.35 max | 0.0003-0.010 | 1 max | 0.50 max |

Mechanical Properties of A453 grade 660 A/B/C/D

| Grade | Class | Tensile Strength (min) – ksi | Tensile Strength (min) – MPa | Yield Strength (0.2 % Offset, min) – ksi | Yield Strength (0.2 % Offset, min) – MPa | Elongation in 4×Diam (min, %) | Reduction of Area (min, %) | Brinell Hardness Number | Approximate Rockwell Hardness – B and C (min) | Approximate Rockwell Hardness – B and C (max) |

|---|---|---|---|---|---|---|---|---|---|---|

| 660 | A, B, and C | 130 | 895 | 85 | 585 | 15 | 18 | 248 – 341 | 24 HRC | 37 HRC |

| 660 | D (≤2½ in. [63.5 mm]) | 130 | 895 | 105 | 725 | 15 | 18 | 248 – 321 | 24 HRC | 35 HRC |

| 660 | D (>2½ in. [63.5 mm]) | 120 | 825 | 95 | 655 | 15 | 18 | 248 – 321 | 24 HRC | 35 HRC |

According to Standard A453, GR 660 alloy is a Fe – 25Ni – 15Cr – based high – temperature alloy, corresponding to GH2132 high – temperature alloy. It is comprehensively strengthened by adding molybdenum, titanium, aluminum, vanadium, and trace amounts of boron. It has high yield strength, creep – rupture strength, and creep strength below 650°C, as well as good workability and satisfactory weldability. It is suitable for manufacturing high – temperature load – bearing components of aero – engines that work for a long time below 650°C, such as compressor disks, rotor blades, and fasteners.

Character of ASTM A453 Grade 660

- High – temperature fatigue resistance: It can withstand operating environments up to 650°C for a long time, making it suitable for exhaust manifolds and turbine fasteners.

- Good dimensional stability: Excellent control of creep and stress relaxation prevents loosening of connectors at high temperatures.

- Superior weldability: Suitable for post – welding treatment of complex geometric parts or assembled components.

- Comprehensive corrosion resistance: Adaptable to harsh environments such as salt fog and high – temperature oxidation, enhancing the reliability of the vehicle system.

Applications of ASTM A453 Grade 660 Round Bar

1. A453 Grade 660 round bar can be used for High-Temperature Bolting

- Turbine casing bolts, heat exchanger studs, and flanged joint fasteners

- Withstands temperatures up to 704°C (1300°F)

- Commonly used in Class A and Class B pressure vessels

2. Power Generation Industry

- Nuclear and thermal power plants

- Bolts and nuts for boiler systems, steam turbines, and reactor pressure vessels

- Resists creep, oxidation, and stress rupture over long operating periods

3. Oil & Gas and Petrochemical Plants

- Ideal for flanged connections, valve components, and compressor bolts

- Performs reliably in hydrogen sulfide (H₂S) and sour gas environments

- Often used in compliance with NACE MR0175 / ISO 15156

4. Aerospace and Aviation

- Suitable for jet engines, exhaust components, and afterburner hardware

- Chosen for its high strength-to-weight ratio and temperature stability

5. Industrial Furnace and Heat Treatment Equipment

- Used in structural supports, fasteners, and hangers inside furnaces

- Retains mechanical integrity even after repeated thermal cycling

6. Marine and Offshore Engineering

- Bolting for subsea equipment, offshore platforms, and LNG infrastructure

- Resistant to chloride-induced stress corrosion cracking

We supply ASTM A453 Grade 660 round bars with full mill test certification (EN 10204 3.1 / 3.2) and adhere to international quality standards. Custom lengths,