ASTM A453 Grade 660 Class A Fasteners Manufacturer

Grade 660 Class A Stud Bolt ,also known as Grade 660 A Stud bolt,refers to a specific type Class A of grade 660 under ASTM A453 Standard,which is a high-temperature, high-strength fastener used in critical applications such as pressure vessels, valves, flanges, and heat exchangers—particularly in the petrochemical, power generation, and aerospace industries.

📄 Download the ASTM A453 Latest edition pdf

Equivalent Materials of A453 grade 660 Class A

- UNS S66286 (A-286)

- Werkstoff 1.4980

- DIN X5NiCrTi26-15

A453 grade 660 Class A stud bolts are produced from High quality ASTM A453 Grade 660 Round bar.

- Diameter Range (Nominal):

- Metric: M6 through M64 (common commercially)

- Imperial (inch): ¼″ – 4″ (¼″, 5⁄16″, 3⁄8″, 7⁄16″, ½″, 5⁄8″, ¾″, 7⁄8″, 1″, 1 1⁄8″, 1 ¼″, 1 ½″, 1 ¾″, 2″,2 1/2″,3″,3 1/2″,4″)

- Length Range:Typically 20 mm up to 1000 mm

ASTM A453 Grade 660 Class A Stud Bolt

| Specification | Details |

|---|---|

| Standard | ASTM A453 |

| Grade | 660 |

| Class | A |

| Material Type | Precipitation-hardened austenitic stainless steel |

| Common Forms | Stud bolts, threaded rods, nuts |

| Temperature Range | Suitable for high-temperature service up to 815°C (1500°F) |

| Surface | Plain finishing or PTFE Coating/Xylan Coating |

| ASTM A453 Grade 660 A Chemical Composition Limits | ||||||||||||||

| Weight% | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | V | Al | B | Co | Cu |

| ASTM A453 GR.660 | 0.08 max | 2 max | 0.025 max | 0.025 max | 1 max | 13.5-16 | 24-27 | 1-1.5 | 1.9-2.35 | 0.10-0.50 | 0.35 max | 0.0003-0.010 | 1 max | 0.50 max |

Mechanical Properties of ATSTM A453 Grade 660 Class A

| Property | Value |

|---|---|

| Tensile Strength | 125 ksi (860 MPa) |

| Yield Strength (0.2% offset) | 105 ksi (725 MPa) |

| Elongation (in 4D) | 15% |

| Reduction of Area | 30% |

| Hardness | 248-341 HBW |

How do we make the ASTM A453 Grade 660 Class A stud bolts and quality Control

Producing ASTM A453 Grade 660 Class A stud bolts involves precise manufacturing processes and stringent quality control (QC) to meet high-temperature, high-strength requirements.

A typical Inspection and test plan for ASTM A453 Grade 660 Class A stud bolt.

| No | Activity / Operation | Characteristics / Description | Reference Standard | Inspection / Test Method | Acceptance Criteria | Responsibility |

| 1 | Raw Material Inspection | Chemical & mechanical certification, traceability | ASTM A453, EN 10204 | Visual + MTC verification | As per ASTM A453 | QA/QC |

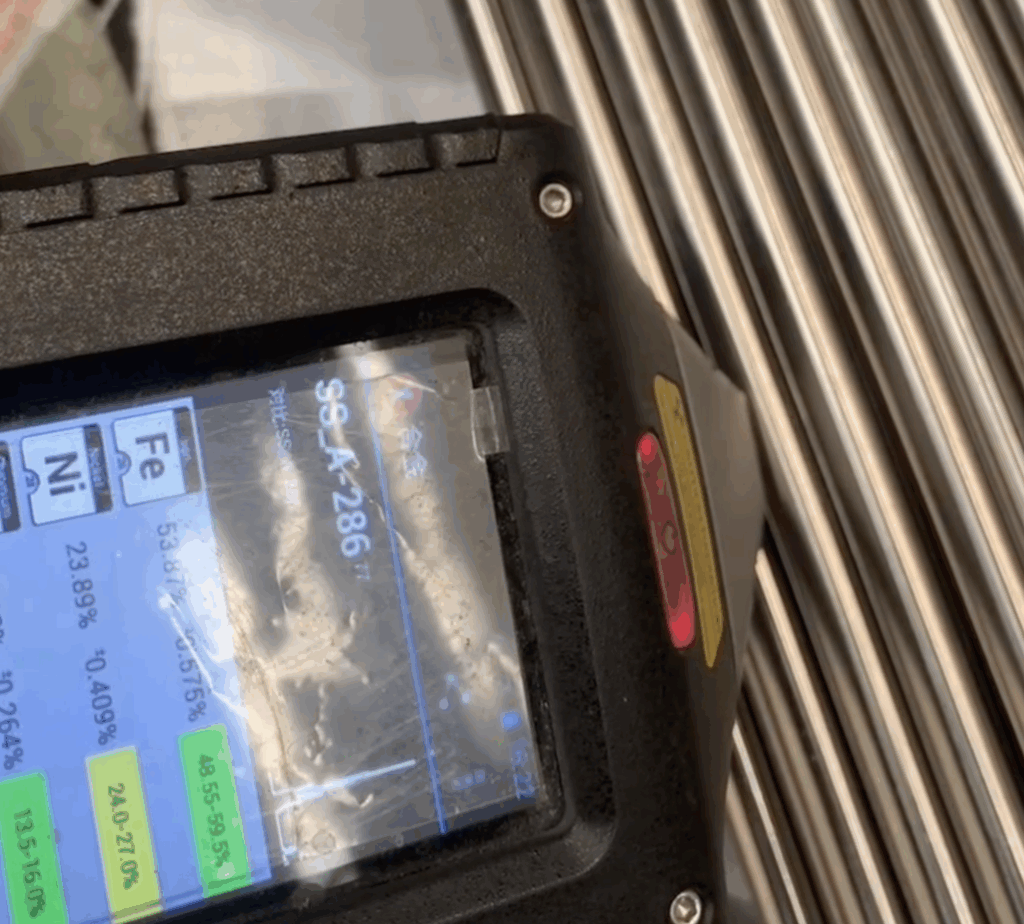

| 2 | Material Identification | PMI (Positive Material Identification) | XRF / OES | Confirm alloy grade | QA/QC | |

| 3 | Cutting | Size check, heat number transfer | Manufacturer SOP | Visual, measuring tools | Dimensional tolerance | Production |

| 4 | Heat Treatment | Solution annealing + aging | ASTM A453 | Heat treatment record | Time/Temp per Class A | QA/QC |

| 5 | Threading | Pitch, major/minor diameter, length | ASME B1.1 / B1.13M | Thread gauge, calipers | ± tolerance | QA/QC |

| 6 | Dimensional Inspection | Full body and thread dimensions | Drawing / Purchase Spec | Vernier, micrometer, gauge | Within tolerance | QA/QC |

| 7 | Chemical composition Testing | Chemical composition Testing | ASTM A453 Grade 660 | ASTM A453 Grade 660 | QA/QC | |

| 8 | Mechanical Testing | Tensile, yield, elongation, RA | ASTM A370 / A453 | UTM | Min: 860 MPa UTS, 725 MPa YS | Third Party / QA/QC |

| 9 | Hardness Test | Brinell or Rockwell | ASTM E18 | Hardness tester | 248- 341 HBW | QA/QC |

| 10 | Surface Finish & Coating | Cleanliness, plating thickness (if coated) | Visual, micrometer | Uniform, crack-free | QA/QC | |

| 11 | Marking | Grade, Heat No., Manufacturer ID | ASTM A453 | Visual | Permanent and legible | QA/QC |

| 12 | Final Inspection | Visual, dimensional, traceability | Purchase Order / Spec | Visual + Measurement | All OK | QA/QC + Client |

Difference between ASTM A453 Grade 660 Class A and Class B

All classes (A, B, C, D) of ASTM A453 Gr 660 use the same base material (precipitation-hardened austenitic stainless steel, UNS S66286), but they are difference in their heat treatment cycles and mechanical property targets.

ASTM A453 Grade 660 – Class A vs. Class B

| Property | Class A | Class B |

|---|---|---|

| Tensile Strength (min) | 860 MPa (125 ksi) | 965 MPa (140 ksi) |

| Yield Strength, 0.2% offset (min) | 725 MPa (105 ksi) | 860 MPa (125 ksi) |

| Elongation in 4D (min) | 15% | 15% |

| Reduction of Area (min) | 30% | 25% |

| Hardness (max) | 248-341 HBW (~37 HRC) | 248-341 HBW (~37 HRC) |

| Heat Treatment | Solution annealed + aged for lower strength | Solution annealed + aged for higher strength |

| Applications | General high-temperature bolting | Higher-load, critical-temperature bolting |

| Ductility | Higher | Lower than Class A (due to increased strength) |

How to chose the right material grade

Which grade is good for your application,ASTM A453 Grade 660 Class A or ASTM A453 Grade 660 Class B Stud bolt

| Class | Best for |

|---|

| ASTM A453 Grade 660 Class A | Applications where moderate strength and better ductility are desired (e.g., pressure vessels, some turbine cases). |

| ASTM A453 Grade 660 Class B | Applications requiring higher strength but with reduced ductility, often in more critical or space-constrained bolted joints. |

As a leading ASTM A453 Grade 660 Class A Stud Bolt manufacturer and supplier, we offer stud bolts with nuts in full compliance with ASTM A453, ASME B18.31.2, ASME B1.1, and ASME B18.2.2. Our fasteners are available in various thread configurations, including UNC, UNF, and metric threads

Related Products

- ASTM A453 Grade 660 Class B/C/D Stud Bolts

- ASTM A193 B8 / B8M Stud Bolts

- ASTM A193 B16 Alloy Steel Stud Bolts

- ASTM A320 L7 / L7M Low-Temperature Stud Bolts