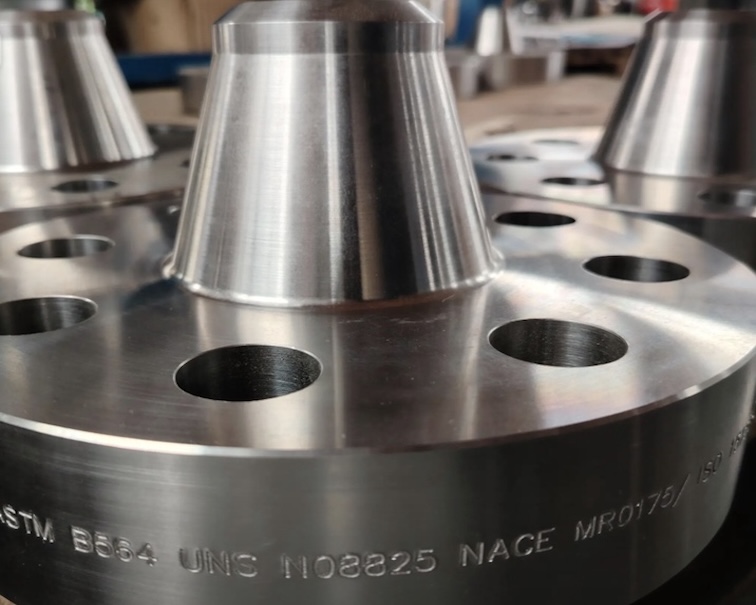

ASTM B564 UNS N08825 Alloy 825 WNRTJ Flange Manufacturer & Supplier

High Quality Alloy 825 WNRTJ Flanges for Corrosive and High-Temperature Applications

We are a professional and expereienced manufacturer and exporter of ASTM B564 UNS N08825 WNRTJ flanges, also known as Alloy 825 Weld Neck Raised Face Ring Type Joint (WNRTJ) flanges. These flanges are widely used in industries such as chemical processing, marine engineering, offshore oil & gas, and pollution control due to their superior resistance to acidic environments, oxidation, and stress corrosion cracking.

What is ASTM B564 UNS N08825?

UNS N08825, also known as Incoloy® 825, Alloy 625,which is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It is designed to provide exceptional corrosion resistance in both oxidizing and reducing environments.

N08825,A nickel-iron-chromium alloy with additions of molybdenum and copper exhibits excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking, and localized attacks such as pitting and crevice corrosion. The alloy is particularly resistant to sulfuric and phosphoric acids and is used in chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Key Features of N08825:

- Excellent resistance to sulfuric and phosphoric acids

- High resistance to pitting, crevice corrosion, and intergranular attack

- Stable mechanical properties at elevated temperatures

A Weld Neck Flange (WN flange) is a high-integrity pipe flange designed to be welded to the end of a pipe, providing a smooth flow transition and strong mechanical connection. It is commonly used in high-pressure, high-temperature, and critical service applications.

N08825 Flanges Specifications

N08825 flanges are made from Incoloy 825 round bars,via forging and machining process.

| Item | Specification |

|---|---|

| Standard | ASTM B564 / ASME SB564 |

| Material Grade | UNS N08825 / Alloy 825 |

| Type | Weld Neck Raised Face Ring Type Joint (WNRTJ),Blind Flange (BL),Slip on flanges(SO) |

| Size Range | 1/2″ to 60″ (DN15 – DN1500) |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#,2500# |

| Facing | RTJ (Ring Type Joint),RF,Raise ,Face |

| Dimensions Standard | ASME B16.5 / B16.47 |

| Heat Treatment | Annealed |

| Certifications | EN 10204 3.1 / 3.2, NACE MR0175, |

Chemical Requirements according to ASTM B564

Nickel-Iron-Chromium-Molybdenum-Copper Alloy UNS N08825

| Element | Composition, % |

| Nickel | 38.0 – 46.0 |

| Copper | 1.5 – 3.0 |

| Iron | 22.0⁸ min |

| Manganese | 1 |

| Carbon | 0.05 |

| Silicon | 0.5 |

| Sulfur | 0.03 |

| Chromium | 19.5 – 23.5 |

| Aluminum | 0.2 |

| Titanium | 0.6 – 1.2 |

| Columbium (Nb) + Tantalum | … |

| Molybdenum | 2.5 – 3.5 |

| Phosphorus | … |

Mechanical Property requirement of N08825

| Material and Condition | Maximum Section Thickness or Diameter, in. (mm) | Tensile Strength, min, ksi (MPa) | Yield Strength, 0.2% Offset, min, ksi (MPa) | Elongation in 2 in. or 50 mm or 4D, min, % |

| UNS N08825, annealed | … | 85 (586) | 35 (241) | 30 |

Test and Certification & Reports for N08825 flanges

All flange is typically delivered with a Mill Test Certificate (EN 10204 3.1 or 3.2), including:

- Chemical composition results

- Mechanical properties

- Heat treatment details

- NDE results (if applicable)

- Traceability (heat number, batch no.)

- PMI

Applications of B564 N08825 WNRTJ Flanges

- Chemical and petrochemical process equipment

- Seawater desalination plants

- Oil and gas refining (especially sour service)

- Heat exchangers and pressure vessels

- Acid and alkali piping systems