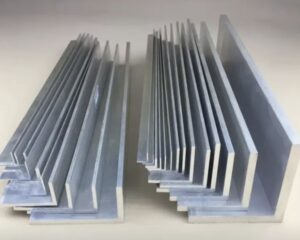

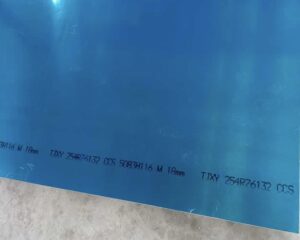

Aluminum 6082 T6 Angle Bar LR DNV ABS certificate

Aluminum 6082 T6 Angle Bar Manufacturer: High-Strength, Corrosion-Resistant Solutions for Structural Applications

6082 T6 is the most popular grade for ship building,it is a high-strength, corrosion-resistant alloy commonly used in structural applications. It offers excellent mechanical properties with good weldability.

Aluminum 6082 T6 Angle Bar LR DNV ABS certificate Read More »