DIN 86019 C70600 Copper-Nickel Pipe | CuNi 90/10 Seamless Tube

The DIN 86019 specifies seamless copper-nickel tubes for corrosion-resistant service. Our CuNi 90/10 (UNS C70600) pipes with exceptional seawater resistance, erosion control, and mechanical strength ,widely used in marine and industrial system

Seamless tubes made of CuNi10Fe1,6Mn for pipes – Dimensions for standard tubes and precision tubes.

DIN 86019 C70600 pipe can be used as the raw material to produce the DIN 86090 elbow,DIN 86088 Tee,cuni pipe fittings.

Standards & Specifications

- Primary Standard: DIN 86019

- Alternate Specs: BS 2871 CN102, EN 12449, EN 1652, ASTM B466

- Pressure Rating: 10 bar for DIN 86019; up to 16 bar under EEMUA 144/234

Chemical Composition (UNS C70600)

| Element | Composition (wt %) |

|---|---|

| Copper (Cu) | Remainder |

| Nickel (Ni) | 9.0–11.0 |

| Iron (Fe) | 1.0–1.8 |

| Manganese (Mn) | ≤ 1.0 |

| Zinc (Zn) | ≤ 1.0 |

| Lead (Pb) | ≤ 0.05 |

| Phosphorus (P) | ≤ 0.02 |

| Sulfur (S) | ≤ 0.02 |

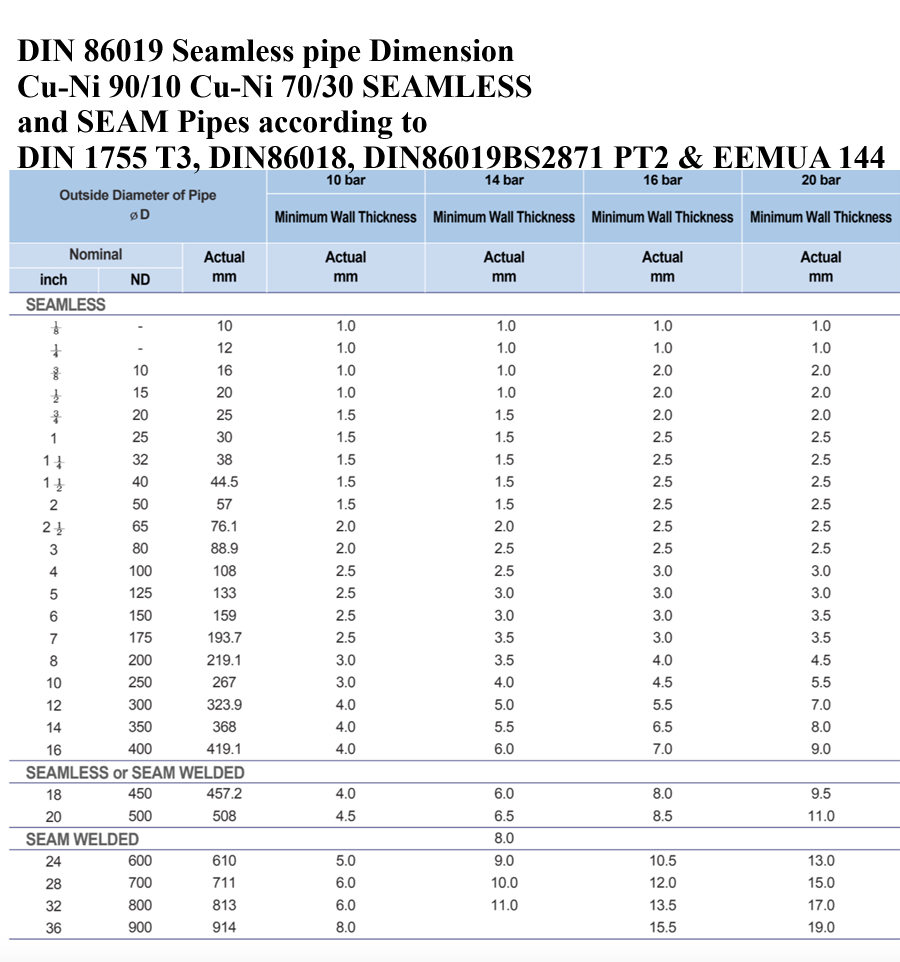

DIN 86019 pipe Dimension

DIN 1755 T3, DIN86018, DIN86019 BS2871 PT2 & EEMUA 144

Size: OD from 8MM to 900MM,

OD ≤ 419mm could be seamless pipes. OD above than 457mm will be welded pipes.

Wall Thickness:10Bar,14bar,16Bar,20Bar, 1 mm to 8 mm.

Pipe Length:6m/pcs or cut length

| Outside Diameter of Cuni 90/10 pipe | DIN 86019 | |||||

| 10 bar | 14 bar | |||||

| ØOutside Diameter | Wall | Theoretical | Wall | Theoretical | ||

| Thickness | Weight | Thickness | Weight | |||

| Nominal | Actual | |||||

| inch | DN | mm | mm | Kg/m | mm | Kg/m |

| 1/8 | 10 | 1 | 0.26 | 1 | 0.26 | |

| 1/4 | 12 | 1 | 0.31 | 1 | 0.31 | |

| 3/8 | 10 | 16 | 1 | 0.42 | 1 | 0.42 |

| 1/2 | 15 | 20 | 1 | 0.53 | 1 | 0.53 |

| 3/4 | 20 | 25 | 1.5 | 0.99 | 1.5 | 0.99 |

| 1 | 25 | 30 | 1.5 | 1.2 | 1.5 | 1.2 |

| 11/4 | 32 | 38 | 1.5 | 1.54 | 1.5 | 1.54 |

| 1 1/2 | 40 | 44.5 | 1.5 | 1.81 | 1.5 | 1.81 |

| 2 | 50 | 57 | 1.5 | 2.34 | 1.5 | 2.34 |

| 2 1/2 | 65 | 76.1 | 2 | 4.16 | 2 | 4.16 |

| 3 | 80 | 88.9 | 2 | 4.88 | 2.5 | 6.07 |

| 4 | 100 | 108 | 2.5 | 7.41 | 2.5 | 7.41 |

| 5 | 125 | 133 | 2.5 | 9.16 | 3 | 10.95 |

| 6 | 150 | 159 | 2.5 | 10.99 | 3 | 13.14 |

| 7 | 175 | 193.7 | 2.5 | 13.43 | 3.5 | 18.7 |

| 8 | 200 | 219.1 | 3 | 18.21 | 3.5 | 21.19 |

| 10 | 250 | 267 | 3 | 22.24 | 4 | 29.55 |

| 12 | 300 | 323.9 | 4 | 35.94 | 5 | 44.78 |

| 14 | 350 | 368 | 4 | 40.89 | 5.5 | 56 |

| 16 | 400 | 419.1 | 4 | 46.62 | 6 | 69.6 |

| 18 | 450 | 457.2 | 4 | 50.91 | 6 | 76.03 |

| 20 | 500 | 508 | 4.5 | 63.63 | 6.5 | 91.55 |

| 24 | 600 | 610 | 5 | 84.96 | 8 | 135.26 |

| 28 | 700 | 711 | 6 | 118.8 | 9 | 177.45 |

| 32 | 800 | 813 | 6 | 135.99 | 10 | 225.53 |

| 36 | 900 | 914 | 8 | 203.57 | 11 | 278.98 |

Typical Applications

- Marine & Offshore: Sea-water cooling, ballast, fire-water lines, and shipbuilding components.

- Desalination Plants: Intake/discharge lines and heat-transfer circuits.

- Chemical & Petrochemical: Corrosive brine handling and process piping.

- Power Generation: Condenser tubes, turbine lube-oil coolers, and cooling water headers.