What is Hardness Testing?

Hardness testing is a physical analysis method for determining the strength of components and is a branch of metallography.

Hardness testing of stud bolts is an essential quality control step to verify their material strength and heat treatment condition

Hardness testing is measuring a material’s resistance to permanent deformation at its surface, by pressing a harder material into it.

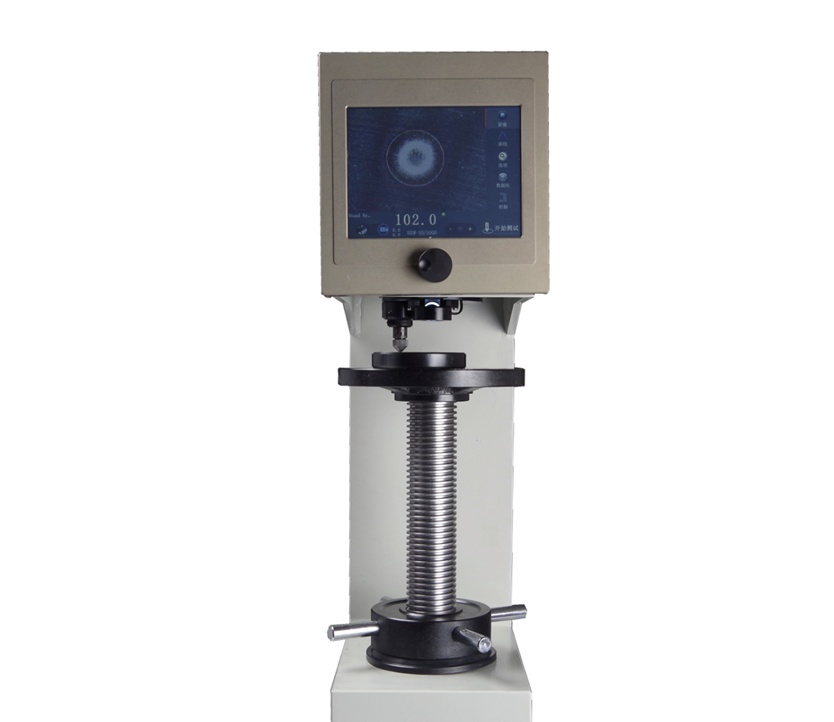

There are several hardness testing methods used for stud bolts, depending on material type and industry requirements:

| Test Method | Scale | Application |

|---|---|---|

| Brinell Hardness Test (HBW) | HBW | Large studs & soft metals (low carbon & alloy steel) |

| Rockwell Hardness Test (HRC, HRB) | HRC / HRB | Medium to hard materials (ASTM A193 B7, B16, L7, etc.) |

| Vickers Hardness Test (HV) | HV | Micro-hardness, thin coatings, precise testing |

| Knoop Hardness Test (HK) | HK | Small & thin components, lab testing |

| Mohs Hardness Test | 1-10 scale | Mineral & scratch resistance test |

Brinell hardness. HBW

hardness value, measured in accordance with ISO 6506-1, normally using a 10-mm diameter tungsten ball and a force of 29,42 kN

Rockwell C hardness

HRC

hardness value, measured in accordance with ISO 6508, obtained using a diamond cone indenter and a force of 1471 N

Vickers hardness

HV

hardness value, measured in accordance with ISO 6507-1, obtained using a diamond pyramid indenter and one of a variety of possible applied loads

Why Hardness testing is required?

Bolting that might be exposed directly to a sour environment, or that will be buried, insulated, equipped with flange

protectors, or otherwise denied direct atmospheric exposure, shall conform to the general requirements of A.2.1.

Designers and users should be aware that it may be necessary to lower equipment pressure ratings when using

SSC-resistant bolting and fasteners. The use of SSC-resistant bolting and fasteners with API flanges shall be in

accordance with ISO 10423.

Hardness testing is essential for stud bolts to ensure they meet the required strength, durability, and resistance to failure under load.

Hardness Limits for Common Stud Bolt Materials

Different stud bolt grades have specific hardness requirements based on industry standards.

| Stud Bolt Grade | Hardness Requirement | Hardness Scale |

|---|---|---|

| ASTM A193 B7 | ≤ 35 HRC or ≥ 248 HBW | Rockwell (HRC) / Brinell (HBW) |

| ASTM A193 B7M | ≤ 235 HBW or ≤ 99 HRB | Brinell (HBW) / Rockwell (HRB) |

| ASTM A193 B16 | ≤ 35 HRC or ≥ 277 HBW | Rockwell (HRC) / Brinell (HBW) |

| ASTM A320 L7 | ≤ 35 HRC or ≥ 248 HBW | Rockwell (HRC) / Brinell (HBW) |

| ASTM A320 L7M | ≤ 235 HBW or ≤ 99 HRB | Brinell (HBW) / Rockwell (HRB) |

| ASTM A320 L43 | ≤ 35 HRC | Rockwell (HRC) |

Hardness Testing Standards and Requirements:

- ASTM E18 – Standard test method for Rockwell hardness of metallic materials

- ASTM E10 – Brinell hardness

- ASTM E384 – Microhardness (Vickers & Knoop)

- EN ISO 6508 / 6506 – International equivalents