Hastelloy C22 (UNS N06022) Flange Manufacturer

Hastelloy® C22 flanges, made from UNS N06022 alloy, offer exceptional resistance to a wide range of aggressive chemical environments, including oxidizing and reducing agents. These high-performance flanges are commonly used in chemical processing, pollution control, marine, and pharmaceutical industries

Hastelloy C-22® alloy is a versatile nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other Ni-Cr-Mo alloys available, including C-276 and C-4 alloys and alloy 625. C-22 alloy has exceptional resistance to a wide variety of chemical process environments, including strong oxidizers such as ferric and cupric chlorides, chlorine, hot contaminated solutions (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions.

B462 C22 flange refers to a forged flange made from UNS N06022 (Hastelloy C-22) in accordance with the ASTM B462 standard.

Standard Specification for Forged or Rolled UNS N06022 and Related Nickel Alloy Pipe Flanges, Forged Fittings, and Valves and Parts for Corrosive High-Temperature Service

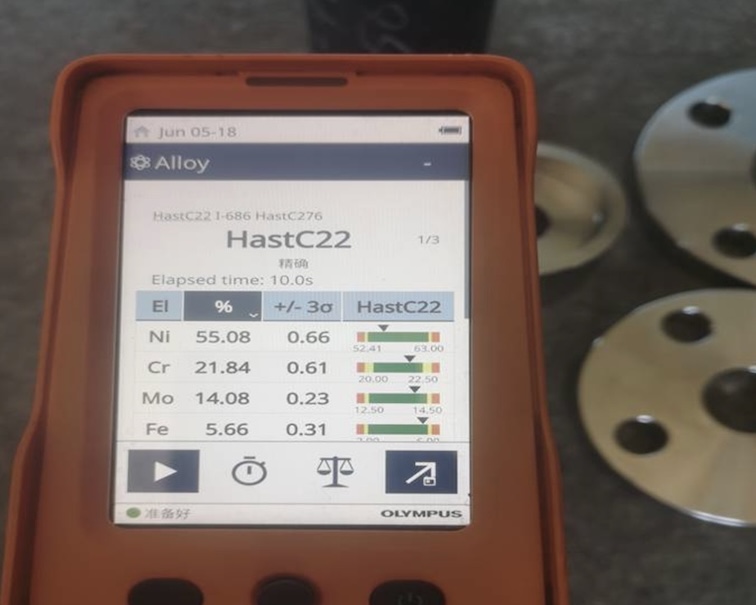

Chemically Composition of N06022

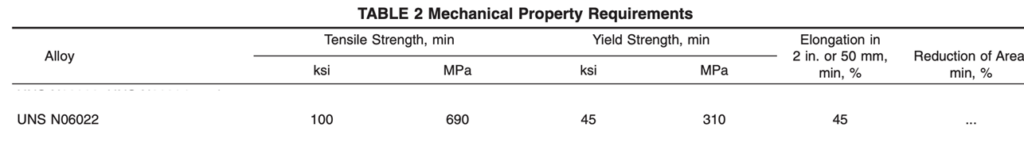

Mechanical Properties of N06022

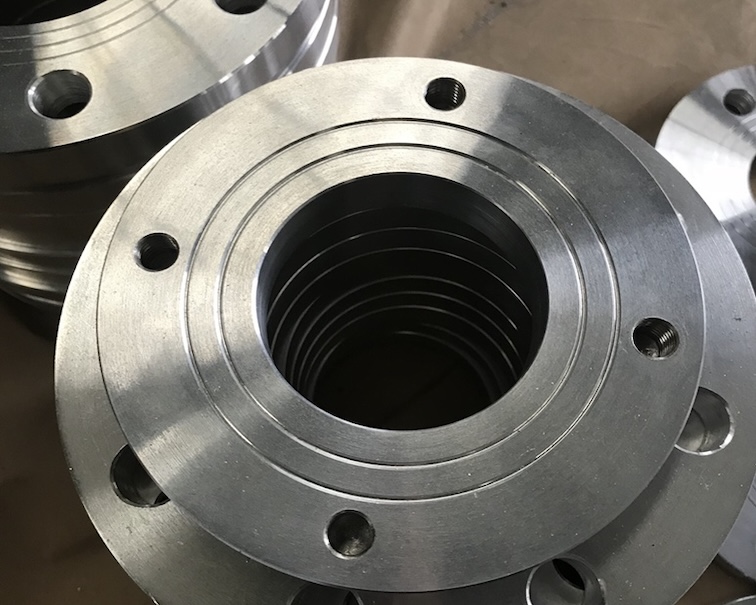

Types of Flanges (per ANSI/ASME B16.5 EN1092-1)

C22 flanges under ASTM B462 are often manufactured in various types:

- Weld Neck (WN)

- Slip-On (SO)

- Socket Weld (SW)

- Blind (BL)

- Threaded (TH)

- Lap Joint (LJ)

Documentation

When ordering or specifying B462 C22 flanges, suppliers should provide:

EN 10204 3.1 / 3.2 MTCs (Mill Test Certificates)