ASTM A262 Intergranular corrosion Test

Intergranular corrosion (IGC), also known as intergranular attack (IGA), is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides.

Intergranular corrosion can reduce ductility and mechanical strength, increasing the risk of failure. Techniques to minimise corrosion risk are available, but testing is essential.

ASTM A262 is the Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

Download ASTM A262 standard pdf free

Intergranular corrosion is a common form of localized corrosion in metals. Corrosion initiates from the metal surface and progresses along the grain boundaries into the interior of the grains, significantly weakening the bonding force between grains. This reduces the strength of the material, and in severe cases, can completely eliminate its mechanical strength. It is one of the highly hazardous forms of localized corrosion.

After a material undergoes intergranular corrosion, there are no obvious external changes, yet its strength has completely vanished, which can lead to the sudden failure of equipment. Therefore, studying the mechanism of intergranular corrosion and adopting effective protective measures are of great significance for national economic construction.

Causes of Intergranular Corrosion

- Media that induce intergranular corrosion in austenitic stainless steels.

- Whether austenitic stainless steels experience intergranular corrosion and the extent of such corrosion within the potential range where it can occur are determined by the steel’s thermal history.

- The reason for intergranular corrosion in austenitic stainless steels is the chromium depletion at the grain boundaries, which is the main cause of intergranular corrosion.

- Another factor influencing intergranular corrosion is carbon. The higher the carbon content in the steel, the greater the tendency of carbon to diffuse to the grain boundaries, resulting in a more severe tendency for intergranular corrosion.

- Electrochemical conditions for intergranular corrosion:

- ① The structures of the grains and the grain – boundary regions are different, resulting in significant differences in their electrochemical properties. The grain boundaries act as anodes and the grains as cathodes. The different potentials of the two electrodes create a potential difference, which is the internal cause for intergranular corrosion.

- ② Corrosion is related to stress and the inhomogeneity of the grain boundaries. The differences between grains and grain boundaries can only be revealed under certain conditions and ambient temperatures.

ASTM A262 Practice A, B, C, E and F Testing

The ASTM A262 tests can determine if the proper heat treatment was performed or if the alloys are in danger of intergranular corrosion occurring in use. These tests are often run as a qualification test to ensure each batch of stainless steel is properly prepared. Each ASTM A262 Practice specification includes a list of the grades of stainless steels and the acceptable etch structures for the specific alloys. For example, many low-carbon and stabilized stainless steels (e.g. 304L, 316L, 317L, and 347) must be subjected to a sensitizing heat treatment prior to testing by the oxalic acid etch test (Practice A).

ASTM A262, Practice A – “Oxalic Acid Test” Oxalic Acid Etch

Practice A, the oxalic acid etch test is used as a rapid technique to screen samples of certain stainless steel grades to ensure they are free of susceptibility to intergranular attack. The test is generally performed for acceptance of materials, but not sufficient for rejection of materials.

ASTM A262 Practice B – “The Streicher Test” Ferric Sulfate – Sulfuric Acid

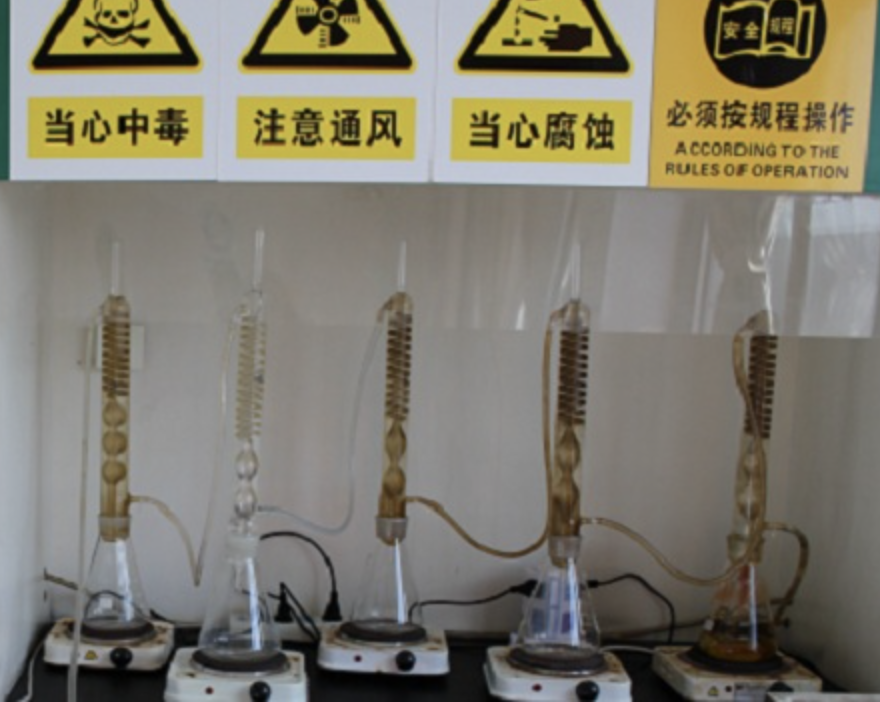

Practice B, also known as the Streicher test, uses weight loss analysis to provide a quantitative measure of the materials performance. This practice includes boiling the sample for 24 to 120 hours in the solution above, and measures the materials performance quantitatively. It is typically used for stainless alloys such as 321 and 347, Cr-Ni-Mo stainless alloys, and nickel alloys to evaluate the intergranular attack associated with the precipitation of chromium carbides at grain boundaries.

ASTM A262, Practice C – “The Huey Test” Nitric Acid

In Practice C, the Huey Test, samples are boiled for five 48-hour periods in a 65% Nitric Acid solution. The weight loss is calculated after each step, and reveals if the sample has been properly heat-treated. Please specify the maximum allowable corrosion rate and any available data on the sensitizing heat treatment performed. The Huey test works well to analyze chromium depleted regions and intermetallic precipitates, such as sigma phase, and is also used for materials in strongly oxidizing environments such as nitric acid

ASTM A262 – Practice E – “The Strauss Test” Copper – Copper Sulfate – 16% Sulfuric Acid

Practice E, the Strauss test, is performed to assess attack associated with chromium-rich carbide formation. The sample is boiled in a Cu-Copper Sulfate mixture and then bent 180° over an equal diameter bend. The test uses a visual inspection of the surface of the bent specimen to determine pass or fail.

Requirements for Intergranular Corrosion Samples

- Plates/strips (section steels):

- When the thickness t<4mm, the sample size is 80mm×20mm×t.

- When 4mm<t, the sample size is 80mm×20mm×(3−4mm).

- Bars/wires/tubes/welded tubes: The length L=80mm. The thickness T=t or T=3−5mm.

- Quantity: 2 samples.

- Tubes with 15mm<OD and 4mm≤t: 4 samples.

- Note: If the outer diameter or wall thickness is too large, contact TS for confirmation of the test specimen.

- Test duration: 16 hours.

ASTM A262 – Practice F Copper – Copper Sulfate – 50% sulfuric acid

Practice F, is a weight-loss based analysis that provides a quantitative measure of the materials performance, and is commonly used to analyzed as-received stainless steels.

Other Standard for Intergranular Corrosion

| Standard | Standard Scope |

| JIS G0571:2003 | 《Method of oxalic acid etching test for stainless steels》 |

| ASTM A262 – 2015 | 《Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels》 |

| ASTM A763 – 2015 | 《Standard Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels》 |

| ISO 11846 – 2008 | 《Corrosion of metals and alloys – Determination of resistance to intergranular corrosion of solution heat – treatable aluminium alloys》 |

| ISO 15329 – 2008 | 《Corrosion of metals and alloys — Anodic test for evaluation of intergranular corrosion susceptibility of heat – treatable aluminium alloys》 |

| ISO 3651 – 1 – 1998 | 《Determination of resistance to intergranular corrosion of stainless steels; Part I :Austenitic and ferritic (duplex) stainless steels– Corrosion test in nitric acid medium by measurement of loss in mass (Huey test)(》 |