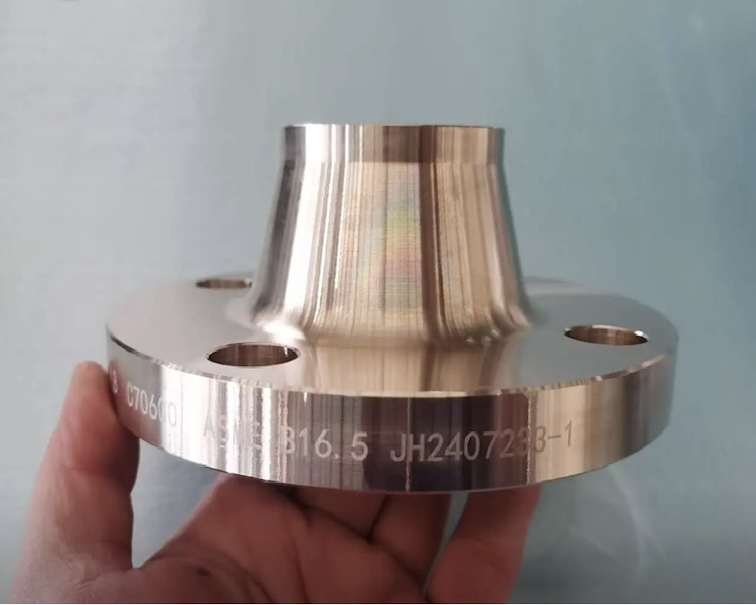

DIN 86088 C70600 CuNi 90/10 Tees Manufacturer

We are a leading DIN 86088 CuNi 90/10 Tees manufacturer in China, supplying premium-quality copper nickel tees and fittings for marine and offshore piping systems. Manufactured using C70600 (CuNi 90/10) alloy, our DIN 86088 tees are ideal for seawater corrosion resistance, ensuring long-lasting performance in harsh environments.

All fittings are produced in compliance with DIN 86088 standards, designed for seamless integration with CuNi pipes in shipbuilding, desalination, power generation, and chemical processing systems.

DIN 86088

Fittings for butt welding into copper-nickel-alloy pipelines – Tees

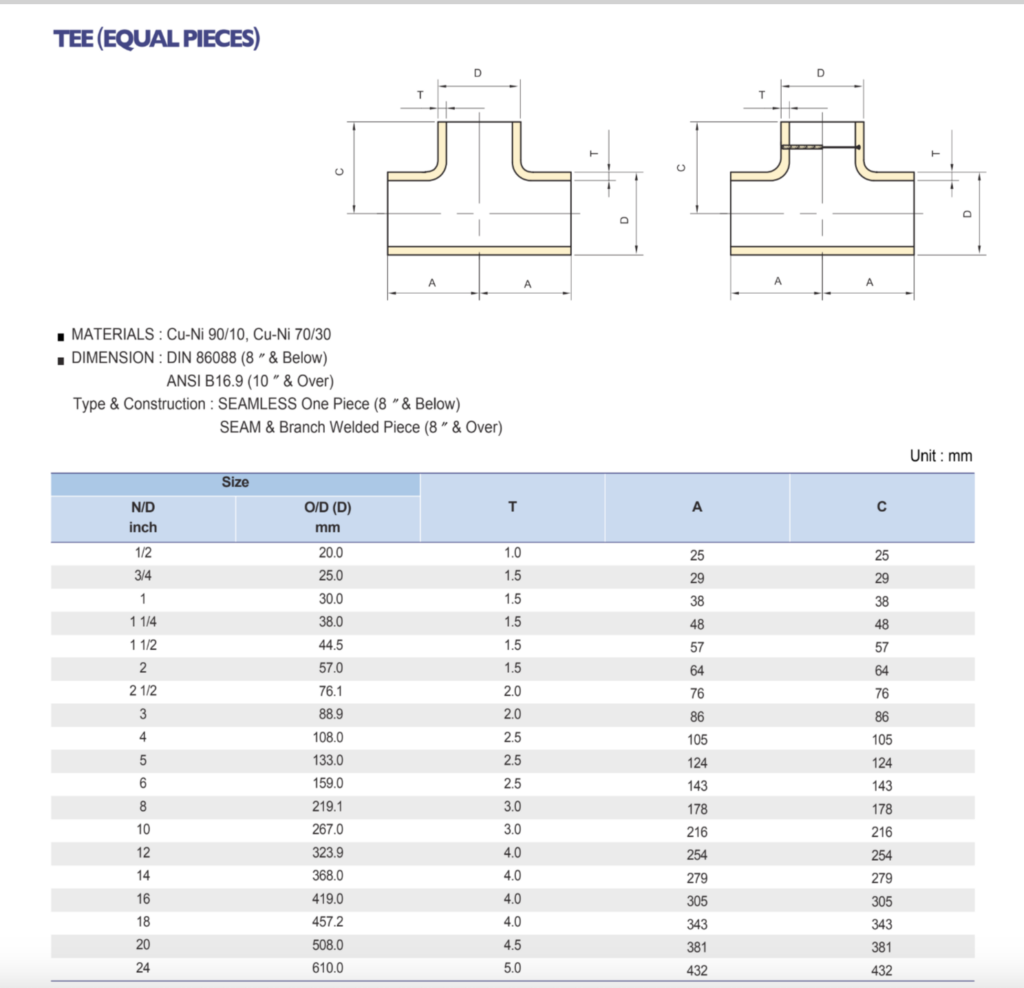

MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30

DIMENSION : DIN 86088

Type & Construction : SEAMLESS (8 & Below)

SEAM WELDED (10 & Over)

A CuNi 90/10 tee is a three-outlet pipe fitting, shaped like the letter “T,” that splits or combines flow in piping systems. Manufactured from copper-nickel alloy containing roughly 90 % copper and 10 % nickel (UNS C70600), these tees deliver outstanding corrosion resistance against seawater

Chemical composition of Cu Ni 90 10 UNS C70600 Copper Nickel

| Alloy No. | Ni% | Fe% | Mn% | C% | Pb% | S% | P% | Zn% | other imp. | Cu% |

| UNS C70600 | 9.0-11.0 | 1.0-2.0 | 0.5-1.0 | max 0.05 | max 0.02 | max 0.02 | max 0.02 | max 0.50 | max 0.03 | rem. |

CuNi 90/10 Tee Dimension according to DIN 86088

Inspection and Testing

Throughout the manufacturing process from melting and alloying to the finished product, stringent quality control inspections and tests are carried out to ensure that product quality complies fully with customers requirements. All tests are performed in accordance with the requirements of the relevent specification. In addition, ultrasonic, radiographic, dye-penetrant, eddy current and other tests can be performed.

For Seam-Welded Fittings it is standard practice to perform 100% radiographic inspection on all welds to ASME, SEC, VIII, UW51; DIN54109, Blatt2 or DIN54111, Teil 1.

Certification

All Butt-Welding Fittings are supplied with a certificate listing the test which have been performed in accordance with relevant specifications and/or customer requests

Related Products

- ASTM B171 C70600 CuNi Blind Flange (ASME B16.5)

- ASTM B466 C70600 Seamless Tubes

- CuNi 70/30 (C71500) Pipes and Fittings

- DIN 86090 CuNi Elbow

- DIN 86088 Cuni Tee

- ASTM B151 C70600 Round Bar

- DIN 86019 C70600 Pipes

- DIN 86037 C70600 Inner Flanges