ASTM A182 F12 Flange Manufacturer

We are a professional manufacturer of ASTM A182 F12 Weld neck Flange ASME B16.5,We supply full range of high-temperature alloy steel forged flanges for power plants, refineries, and petrochemical industries. Our flanges are precision-forged from F12 Class 1 or Class 2 material, with full compliance to ASME, ASTM, and ANSI standards.

ASTM A182 F12 is a Cr-Mo (Chromium-Molybdenum) alloy steel, designed for high-temperature and high-pressure service in applications such as power plants, refineries, and petrochemical systems. F12 is a Class 1 or Class 2 grade typically used in forged flanges, fittings, valves, and other pressure-containing components.

ASTM A182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service

There are 2 classes for F12 grade.ASTM A182 F12 Class 1,ASTM A182 F12 Class 2,

- F12 CL1 has a UNS Designation of K11562.

- F12 CL2 has a UNS Designation of K11564.

Chemical Requirements of A182 F12

| Elements | F12 Class1 | F12 Class2 |

| Carbon | 0.05-0.15 | 0.10-0.20 |

| Manganese | 0.30-0.60 | 0.30-0.60 |

| Phosphorus | 0.045 | 0.040 |

| Sulfur | 0.045 | 0.040 |

| Silicon | Max 0.50 | 0.10-0.60 |

| Chromium | 0.80-1.25 | 0.80-1.25 |

| Molybdenum | 0.44-0.65 | 0.44-0.65 |

A182 F12 Flange Tensile and Hardness Requirements

| Grade Symbol | F12 Class1 | F12 Class2 |

| Tensile Strength,min, ksi [Mpa] | 60[415] | 70[485] |

| Yield Strength, min,ksi [MPa] | 32[220] | 40[275] |

| Elongation in 2 in.[50 mm] or 4D,min, % | 20 | 20 |

| Reduction of Area, min, % | 45 | 30 |

| Brinell HardnessNumber | 121-174 | 143-207 |

ASTM A182 F12 Flange specification

Material: ASTM A182 F12 (Alloy Steel, Cr-Mo)

Class: Class 1 or Class 2

Standards: ASME B16.5, B16.47, MSS-SP-44

Sizes: ½” to 60” (Custom sizes available)

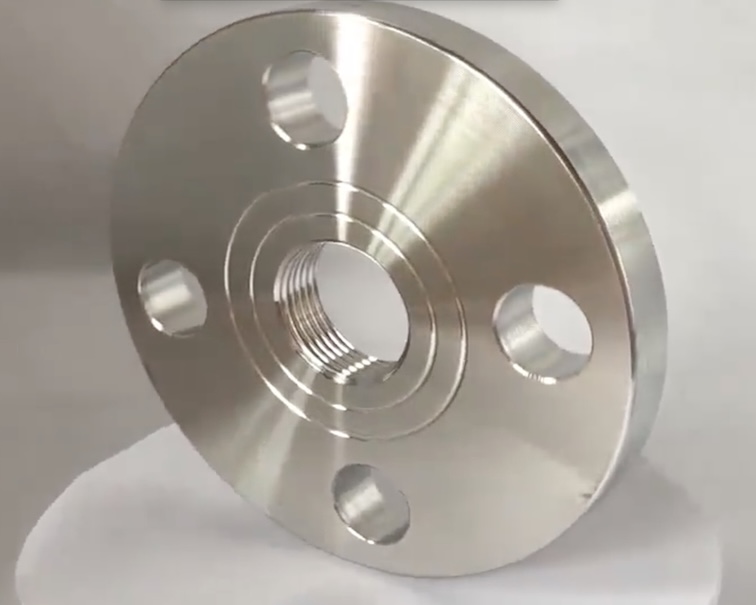

We supply a wide range of forged flanges in ASTM A182 F12 material, including:

- ASTM A182 F12 Weld Neck (WN) Flange

- ASTM A182 F12 Slip-On (SO) Flange

- ASTM A182 F12 Blind (BL) Flange

- Socket Weld (SW) Flange

- Lap Joint (LJ) Flange

- Threaded (TH) Flange

- Long Weld Neck (LWN) Flange

A182 F12 Flanges Heat Treatment Requirements

- Normalize and Temper:

- Austenitizing temperature: 1650∘F(900∘C).

- Cooling media: Air cool (after normalizing).

- Tempering temperature: 1150∘F(620∘C).

Additionally, after hot working, forgings should be cooled to a temperature below 1000∘F(538∘C) before heat treatment to meet the requirements.

| Grade | Required Heat Treatment |

|---|---|

| F12 | Normalized and Tempered OR Annealed |

A182 F12 Weld neck flange Nondestructive Testing (if required by purchaser)

- Visual Inspection: Required

- Ultrasonic Testing (UT): Optional

- Magnetic Particle (MT) or Liquid Penetrant Testing (PT): Optional, for surface crack detection

ASTM A182 F12 weld neck flanges manufactured to ASME B16.5 provide reliable strength, oxidation resistance, and long-term performance in high-temperature pressure systems. With proven performance in refineries and power plants, F12 alloy steel flanges are a trusted choice for critical piping applications.

Looking for a high-performance alloy steel flange for elevated temperature and pressure applications? Our ASTM A182 F12 flanges are engineered to deliver exceptional strength, durability, and corrosion resistance in demanding industrial environments.