GOST 9941 12X18H10T Stainless steel seamless pipe Manufacturer

12X18H10T or 12h18n10t is an austenitic stainless chromium-nickel steel with a low titanium content.

The equivalent grade of 12X18H10T is AISI 321

Gost 9941 is a Russian state standard that specifies technical requirements for seamless stainless steel tubes intended for industrial applications, including high-pressure, high-temperature, and corrosion-resistant systems.

Pipe Dimensions Scope (as per GOST 9941)

| Parameter | Range |

|---|---|

| Outside Diameter | 6 mm – 273 mm |

| Wall Thickness | 0.5 mm – 22 mm |

Equivalent Standards:

- AISI 321 / ASTM A312 TP321

- EN 1.4541 / X6CrNiTi18-10

Chemical composition in % for grade 12KH18N10T ( 12Х18Н10Т )

| C | Si | Mn | Ni | S | P | Cr | Cu | – |

| max 0.12 | max 0.8 | max 2 | 9 – 11 | max 0.02 | max 0.035 | 17 – 19 | max 0.3 | (5 С – 0.8) Ti, остальное Fe |

Mechanical Properties at 20 °C of the Metal of Thermally – Processed Tubes with a D/S Ratio Less Than 40

| Steel Grade | Yield Strength σв, N/mm² | Yield Limit σ0.2, N/mm² | Relative Elongation δ5, % |

|---|---|---|---|

| 12X18H10T | 549 | 1) | 35 |

GOST 9941 12X18H10T Seamless Pipe Permissible Deviations of the Outer Diameter

| Steel Grade | Outer Diameter, MM | Permissible Deviation for Manufacturing Accuracy | ||

| Ordinary | Increased | High | ||

| All, except 06Х28МДТ | Up to 10 inclusive | ±0.30 MM | ±0.20 MM | ±0.15 MM |

| Over 10 – 30 | ±0.40 MM | ±0.30 MM | ±0.20 MM | |

| Over 30 – 95 | ±1.2 % | ±1.0 % | ±0.8 % | |

| Over 95 (with D/S ratio less than 40) | ±1.2 % | ±1.0 % | ±0.8 % | |

| Over 95 (D/S 40 and more) | ±1.5 % | ±1.2 % | ±1.0 % |

GOST 9941 12X18H10T Seamless Pipe Permissible Deviations of the wall thickness

| Steel Grade | Wall Thickness, MM | Permissible Deviation for Manufacturing Accuracy | ||

| Ordinary | Increased | High | ||

| All, except 06Х28МДТ | Less than 0.3 | ±0.05 MM | ±0.03 MM | — |

| From 0.3 to 0.4 inclusive | ±0.07 MM | ±0.05 MM | — | |

| Over 0.4 – 0.6 | ±0.10 MM | ±0.07 MM | — | |

| Over 0.6 – 1.0 | ±0.15 MM | ±0.10 MM | — | |

| Over 1.0 – 3.0 | 12.50% | 12.50% | 12.50% | |

| −15.0 % | −15.0 % | −10.0 % | ||

| Over 1.0 – 3.0 (with D/S ratio 40 and more) | ±15.0 % | 12.50% | — | |

| −15.0 % | ||||

| Over 3.0 – 7.0 (with D/S ratio less than 40) | ±12.5 % | 12.50% | ±10.0 % | |

| −10.0 % | ||||

| Over 3.0 – 7.0 (with D/S ratio 40 and more) | 12.50% | ±12.5 % | — | |

| −15.0 % | ||||

| Over 7.0 (with outer diameter less than 325 MM) | 12.50% | ±10.0 % | — | |

| −10.0 % | ||||

| Over 7.0 (with outer diameter 325 MM and more) | 12.50% | ±12.5 % | — | |

| −15.0 % |

GOST 9941 12X18H10T Pipes Heat Treatment:

- Pipes are typically supplied in the solution annealed condition (around 1050–1100°C), followed by water or air quenching.

GOST 9941 12X18H10T Pipe Testing Requirements:

- Hydrostatic or Eddy Current Testing (as required)

- Dimensional and Visual Inspection

- Chemical Composition Analysis

- Mechanical Testing (tensile, elongation, hardness)

- Optional: Intergranular corrosion test (per GOST 6032 or ASTM A262 Practice E)

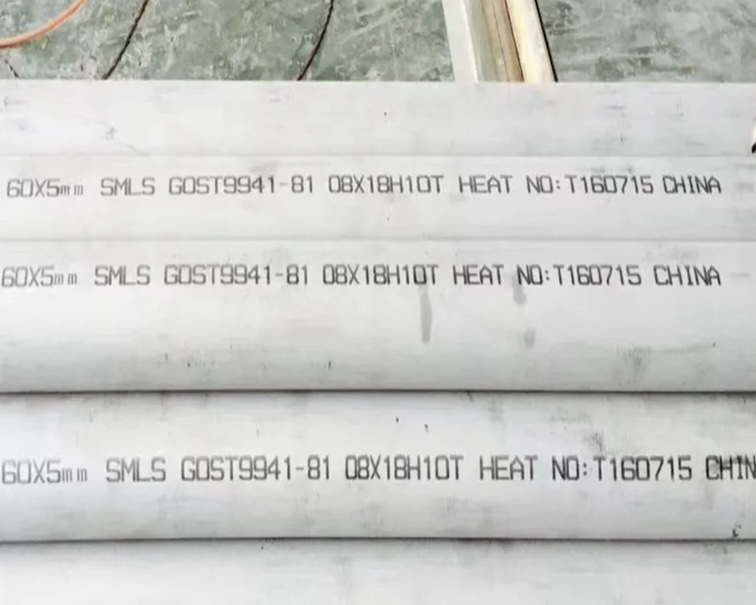

GOST 9941 Pipe Marking & Certification:

Each pipe is marked with:

- Steel grade (12X18H10T)

- Size and standard (GOST 9941)

- Manufacturer’s name or code

- Heat number or batch number

Certificates typically include:

- Mill Test Certificate (MTC) per EN 10204 3.1 / 3.2