ASTM A694 / A694M Flanges Specification

As a professional manufacturer and exporter of ASTM A694 High-Yield Carbon Steel Flanges, including Weld Neck, Blind, Slip On, Socket Weld, and Threaded Flanges.

These flanges are widely used in high-pressure oil, gas, and petrochemical pipelines, where strength, toughness, and corrosion resistance are essential.

ASTM A694 is a standard specification published by ASTM International that covers carbon and alloy steel forgings for pipe flanges, fittings, valves, and parts for high-pressure transmission service.

ASTM A694 have several grades from F42,F52,F60,F65 to F70,

Those Grades are selected to match API pipe grades (e.g., API 5L X60, X65)

Typically used in the manufacturing of:

- Weld neck flanges

- Slip-on flanges

- Blind flanges

- Reducing flanges

- Forged fittings and valves

ASTM A694 flanges are commonly used in oil & gas pipelines, refineries, petrochemical plants, and power generation projects where reliability and strength are critical.

Manufactured to meet the stringent requirements of the ASTM A694 standard, these flanges are available in a wide range of pressure classes (150# to 2500#) and sizes (½” to 48″), ensuring compatibility with ASME B16.5, ASME B16.47, and API 6A specifications.

ASTM A694 Flanges Specifications:

1. ASTM A694 standard Scope

1.1 This specification covers forged or rolled steel pipe flanges, forged fittings, valves, and parts suitable for use with high-strength transmission-service pipe. Included are flanges, fittings, and similar parts ordered either to dimensions specified by the purchaser or to ASME or MSS dimensional standards referenced in Section 2.

1.2 Several grades of material, based on minimum yield strength requirements, are covered, as indicated in Table 1.

1.3 Supplementary Requirements are provided. Supplementary Requirement S1 is provided for use when purchaser approval is required for repair welding.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exactly equivalent; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

2. Referenced Documents

2.1 In addition to those reference documents listed in Specification A961/A961M, the following list of standards apply to this specification:

2.2 ASTM Standards:

- A53/A53M Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- A106/A106M Specification for Seamless Carbon Steel Pipe for High-Temperature Service

- A381 Specification for Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems

- A707/A707M Specification for Forged Carbon and Alloy Steel Flanges for Low-Temperature Service

- A788/A788M Specification for Steel Forgings, General Requirements

- A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

2.3 ASME Standards: - ASME B 16.5 Steel Pipe Flanges and Flanged Fittings

- ASME B 16.9 Steel Butt-Welding Fittings

- ASME B 16.11 Forged Steel Fittings, Socket Welding and Threaded

- ASME B 16.47 Large Diameter Steel Flanges

2.4 MSS Standards: - MSS SP-44 Standard for Steel Pipe Line Flanges

- MSS SP-75 Specification for High-Test Welding Fittings

- MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings

2.5 API Standard: - 5L Specification for Line Pipe

3. Ordering Information

3.1 It is the purchaser’s responsibility to specify in the purchase order all ordering information necessary to purchase the needed material. In addition to the ordering guidelines in Specification A961/A961M, orders should include the following information:

- 3.1.1 Additional requirements (see 8.1 and 11.1).

4. General Requirements

4.1 Product furnished to this specification shall conform to the requirements of Specification A961/A961M, including any supplementary requirements that are indicated in the purchase order. Failure to comply with the general requirements of Specification A961/A961M constitutes nonconformance with this specification. In case of conflict between the requirements of this specification and Specification A961/A961M, this specification shall prevail.

5. Manufacture

5.1 Melting Process:

- 5.1.1 The steel shall be made by any of the following processes: open hearth, electric furnace, or basic oxygen. The steel shall be fully deoxidized.

- 5.1.2 The steel shall be carbon steel, high-strength low-alloy steel, or alloy steel, as agreed upon between the manufacturer and purchaser. Analysis of the steel used, including all alloying elements listed in Table 2, shall be reported by the manufacturer to the purchaser. The steel shall be suitable for field welding (as established by the purchaser) to other fittings, valve materials and flanges, and to pipe manufactured under the following ASTM specifications: Specification A53/A53M, Specification A106/A106M, Specification A381, and API Standard 5L pipe, as well as to fittings manufactured under MSS SP-75.

5.2 Manufacturing Practice: - 5.2.1 Material for forgings shall consist of ingots or blooms, billets, slabs, or bars of forged or rolled form and cut to the required length by a suitable process.

- 5.2.2 The finished product shall be a forging as defined in the Terminology section of Specification A788/A788M.

- 5.2.3 Hot working shall be sufficient to develop a wrought structure throughout the part.

- 5.2.4 Flanges shall not be machined directly from plate nor from solid bar stock.

5.3 Heat Treatment: - 5.3.1 All items shall be heat treated. Heat treatment of carbon steel and high-strength low-alloy steel may consist of normalizing, normalizing-and-tempering, or quenching-and-tempering. Heat treatment of alloy steel may consist of normalizing and precipitation heat treatment or quenching and precipitation heat treatment.

- 5.3.2 The tempering temperature shall be at least 1000 °F [540 °C]. The precipitation heat treatment of the alloy steel shall be in the range from 1000 to 1225 °F [540 to 665 °C].

6. Chemical Composition

6.1 A chemical heat analysis in accordance with Specification A961/A961M shall be made and conform to the requirements as to chemical composition prescribed in below table

6.2 High-strength low-alloy steels shall be of specified alloy element composition, with the elements covered in 6.1 restricted within the limits prescribed therein as may be necessary to ensure weldability and specified minimum tensile properties. When high-strength low-alloy steel is furnished, appropriate procedures are required for field welding.

6.3 Alloy steel shall conform to the requirements for Grade L5 of Specification A707/A707M.

TABLE 2 Chemical Requirements

⁴All elements listed in Table 2 shall be reported. Where no composition limit is listed, values are to be reported but no limits apply except as covered in 6.3.

| Composition, % | Heat Analysis |

|---|---|

| Carbon, max | 0.30 |

| Manganese, max | 1.60 |

| Phosphorus, max | 0.025 |

| Sulfur, max | 0.025 |

| Silicon | 0.15–0.35 |

| Copper⁴ | |

| Nickel⁴ | |

| Chromium⁴ | |

| Molybdenum⁴ | |

| Vanadium⁴ | |

| Columbium (Niobium)⁴ | |

| Boron⁴ |

7. Tensile Requirements

7.1 The material shall conform to the requirements as to tensile properties prescribed in Table 1, when tested in accordance with the mechanical testing requirements of Specification A961/A961M.

7.2 The tension test specimen shall be obtained from a production forging, or from an integral prolongation representative of the hub location of a flange, or the heaviest cross section of a fitting, valve, or other part within the scope of this specification. Alternatively, the test specimen may be taken from a separately forged test block which has been taken from the same heat of steel as the production forgings, and which has been reduced by forging in a manner similar to that for the forgings it represents.

- 7.2.1 The test specimen shall represent all forgings from the same heat and heat treatment load whose maximum thicknesses do not exceed the thickness of the test forging or blank by more than ¼ in. [6 mm].

7.3 The axis of the tension test sample shall be located in the test forging, or prolongation so as to represent mid-wall of the flange hub, or mid-wall of the thickest cross section of the valve, fitting, or other part.

7.4 The axis of the tension test specimen shall be oriented parallel to the direction of maximum forging work for fittings, valves, and other parts, except for flanges when the specimen shall be oriented in the tangential direction.

7.5 One tension test shall be taken from each heat in each heat treatment load, and shall be representative of the largest flange hub, or valve or fitting wall thickness in the load.

7.6 When heat treatment is done either in continuous or batch type furnaces in which the working zones are controlled to within ± 25 °F [± 14 °C] of the required heat treatment temperature, and when the furnace is equipped with function-recording pyrometers that complete heat treatment records are available, then one tension test from each heat shall be required instead of one from each heat in each heat treatment load. However, this provision is limited to forgings with heat treated weights not exceeding 10 000 lb [4540 kg], and the test forging must accompany a production charge.

TABLE 1 Tensile Requirements of ASTM A694

| Grade | Yield Strength (0.2 % Offset), min, ksi [MPa] | Tensile Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm, min % |

|---|---|---|---|

| F42 | 42 [290] | 60 [415] | 20 |

| F46 | 46 [315] | 60 [415] | 20 |

| F48 | 48 [330] | 62 [425] | 20 |

| F50 | 50 [345] | 64 [440] | 20 |

| F52 | 52 [360] | 66 [455] | 20 |

| F56 | 56 [385] | 68 [470] | 20 |

| F60 | 60 [415] | 75 [515] | 20 |

| F65 | 65 [450] | 77 [530] | 20 |

| F70 | 70 [485] | 82 [565] | 18 |

8. Surface Finish, Appearance, and Corrosion Protection

8.1 The forgings and fittings shall conform to the requirements of Specification A961/A961M.

9,Heat Treatment

- All forgings must be normalized, normalized and tempered, or quenched and tempered.

- Intended to enhance toughness and resistance to cracking.

10. Repair by Welding

9.1 Repair by Welding of Injurious Defects—Repair of injurious defects shall be permitted at the discretion of the manufacturer in accordance with Specification A961/A961M.

- 9.1.1 Deposited weld metal shall be capable of meeting all mechanical properties upon heat treatment.

- 9.1.2 All forgings to be repaired by welding shall be repair welded prior to heat treatment.

11. Retests

If any of the results of the tension tests of any lot do not conform to the requirements specified, the manufacturer may reheat treat such lots, but not more than twice, except with the approval of the purchaser, on the basis of satisfactory metal-lurgical evidence that the cause of failure is curable and the quality of the material is satisfactory.

12. Rejection and Rehearing

11.1 The purchaser shall comply with the requirements of Specification A961/A961M.

13. Certification

- MTC (Material Test Certificate) required

12.1 See Specification A961/A961M.

12.2 The test report shall include the following:

- 12.2.1 Chemical analysis results,

- 12.2.2 Tensile properties, report the yield strength and tensile strength, in ksi [MPa], elongation and reduction in area

- 12.2.3 Type heat treatment,

- 12.2.4 Any supplementary testing required by the purchase order.

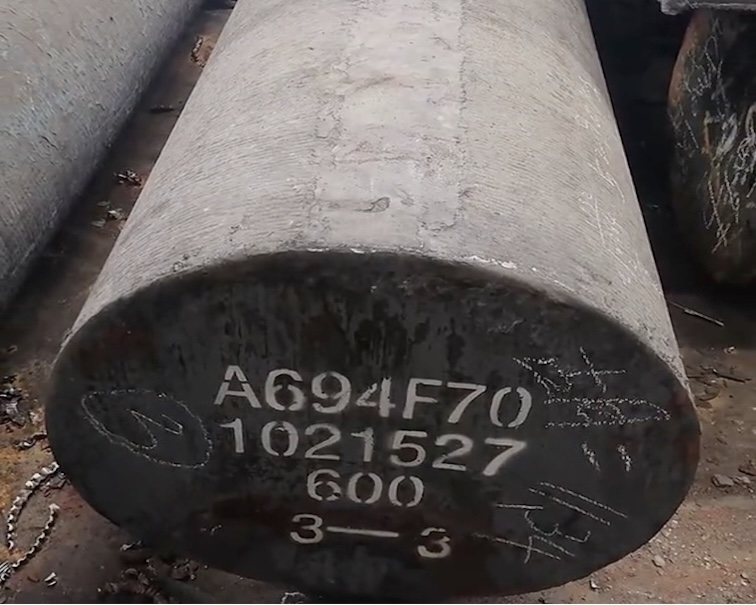

14. Product Marking

13.1 In addition to marking requirements of Specification A961/A961M, the following additional marking requirements shall apply:

Forgings shall be marked with:

- ASTM A694

- Grade (e.g., F60)

- Heat number

- Manufacturer’s name/logo

- Standard + Size/class

- Traceability marks

Applications

- Oil & Gas Transmission Pipelines

- Offshore and Subsea Installations

- Petrochemical and Refining Units

- Power Generation Plants

- LNG Terminals and Cryogenic Systems

- Process Piping and Compressor Stations

Certification: EN 10204 3.1, PED 2014/68/EU, NACE MR0175 / MR0103, ISO 15156, upon request.

Order Example: ASTM A694 Flanges

Product: Weld Neck Flange

Standard: ASTM A694 / ASME B16.5

Grade: ASTM A694 F65

Nominal Size: 10″

Pressure Rating: Class 600

Facing: RF (Raised Face)

Dimensions: As per ASME B16.5

Type: Forged, Heat Treated, Machined

Quantity: 12 Pieces

Inspection: EN 10204 3.1 Mill Test Certificate

Origin: Made in China

Application: Natural Gas Transmission Pipeline

Related Products

- ASTM A105 Carbon Steel Flanges

- ASTM A350 LF2 Low-Temperature Flanges

- ASTM A694 F52 / F60 / F65 Weld Neck Flanges

- ASME B16.47 Series A/B Large Diameter Flanges

- ASTM A420 WPL6 Pipe Fittings