ASTM A182 F304 / F304L Stainless Steel Flanges Manufacturer & Supplier

We are a professional manufacturer and global exporter of ASTM A182 F304 and F304L stainless steel flanges, available in a wide variety of types including Weld Neck (WN), Slip-On (SO), Blind (BL), Socket Weld (SW), and Threaded (TH) flanges.

ASTM A182 / A182M – Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service

Download ASTM A182 2024 pdf

⬇️ Download ASTM A182-24 Now (PDF)

ASTM A182 covers:

- Forged or rolled alloy steel materials

- For use in pressure systems and high-temperature services

- Commonly applied in:

- Petrochemical plants

- Oil & gas processing

- Power generation (thermal, nuclear)

- Marine and offshore industries

ASTM A182 Flange Types Available

ASTM A182 alloy steel flanges are manufactured in compliance with:

- Specifications: ASTM A182 / ASME SA182

- Dimensions: ASME B16.5, B16.47, DIN, EN1092-1, BS4504

- Size Range: ½” to 48” (DN15–DN1200)

- Face Type: RF (Raised Face), FF (Flat Face), RTJ (Ring-Type Joint)

Available types:

- ASTM A182 F304/304L Weld Neck Flange (WN)

- ASTM A182 F304/304L Blind Flange (BL)

- ASTM A182 F304/304L Slip-On Flange (SO)

- ASTM A182 F304/304L Socket Weld Flange (SW)

- ASTM A182 F304/304L Threaded Flange (TH)

- Lap Joint Flange (LJ)

- Orifice Flanges

SS304 stainless steel is the most common austenitic stainless steel. It is an alloy of iron, carbon, chromium and nickel. There are 2 grade in SS304.ASTM A182 F304” and “ASTM A182 F304L” ,They are the same material grade level,but the only difference in the compostion is that,304L with a lower carbon content,We can supply A182 F304/F304L dual grade flanges.

F304 is a standard 18/8 stainless steel (18% Cr, 8% Ni) with good corrosion resistance and strength.

F304L is the low-carbon version of F304, ideal for welded applications to avoid carbide precipitation and intergranular corrosion.

ASTM A182 is the a standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service.

Chemical Composition of A182 F304/F304L

| Material | C | Mn | P | S | Si | Ni | Cr |

| A182 F304 | Max 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 |

| A182 F304L | Max 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-13.0 | 18.0-20.0 |

Tensile and hardness requirement of A182 F304/F304L

| Property | F304 | F304L |

|---|---|---|

| Tensile Strength | ≥515 MPa | ≥485 MPa |

| Yield Strength | ≥205 MPa | ≥170 MPa |

| Elongation | ≥30% | ≥30% |

| Hardness (HB) | ≤192 | ≤192 |

ASTM A182 304/304L Flange Manufacture

The stainless steels shall be melted by one of the following processes: (a) electric-furnace (with the option of separate degassing and refining processes); (b) vacuumfurnace; or (c) one of the former followed by vacuum or electroslag-consumable remelting

ASTM A182 304/304L Flange Heat treatment

| Grade | Heat Treat Type | Austenitizing/ Solutioning Temperature, Minimum or Range,°F [°C] | cooling Media | Quenching Cool Below °F [°C] | Tempering, Temperature, Minimum or Range,°F [°C] |

|---|---|---|---|---|---|

| F304 | solution treat and quench | 1900 [1040] | liquid | 500 [260] | B |

| F304L | solution treat and quench | 1900 [1040] | liquid | 500 [260] | B |

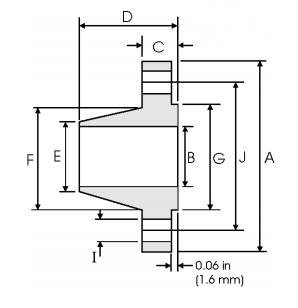

Dimension of A182 F304/304L Weld Neck flanges ASME B16.5

ASME B16.5 Class 150 lb Weld Neck Flange Dimensions & Weight

| NPS | A | B | C | D | E | F | G | H | I | J | W |

| inch | inch | inch | inch | inch | inch | inch | No. of Holes | inch | inch | kg/pc | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| 1/2 | 3.500 | 0.620 | 0.440 | 1.880 | 0.840 | 1.190 | 1.380 | 4 | 0.620 | 2.380 | 0.48 |

| 88.90 | 15.70 | 11.20 | 47.80 | 21.30 | 30.20 | 35.00 | 15.70 | 60.45 | |||

| 3/4 | 3.880 | 0.820 | 0.500 | 2.060 | 1.050 | 1.500 | 1.690 | 4 | 0.620 | 2.750 | 0.71 |

| 98.60 | 20.80 | 12.70 | 52.30 | 26.70 | 38.10 | 42.90 | 15.70 | 69.85 | |||

| 1 | 4.250 | 1.050 | 0.560 | 2.190 | 1.320 | 1.940 | 2.000 | 4 | 0.620 | 3.120 | 1.01 |

| 108.0 | 26.70 | 14.20 | 55.60 | 33.50 | 49.30 | 50.80 | 15.70 | 79.25 | |||

| 1-1/4 | 4.620 | 1.380 | 0.620 | 2.250 | 1.660 | 2.310 | 2.550 | 4 | 0.620 | 3.500 | 1.33 |

| 117.3 | 35.10 | 15.70 | 57.15 | 42.20 | 58.70 | 63.50 | 15.70 | 88.90 | |||

| 1-1/2 | 5.000 | 1.610 | 0.690 | 2.440 | 1.900 | 2.560 | 2.880 | 4 | 0.620 | 3.880 | 1.72 |

| 127.0 | 40.90 | 17.50 | 62.00 | 48.30 | 65.00 | 73.15 | 15.70 | 98.60 | |||

| 2 | 6.000 | 2.070 | 0.750 | 2.500 | 2.380 | 3.060 | 3.620 | 4 | 0.750 | 4.750 | 2.58 |

| 152.4 | 52.60 | 19.10 | 63.50 | 60.45 | 77.70 | 91.90 | 19.10 | 120.7 | |||

| 2-1/2 | 7.000 | 2.470 | 0.880 | 2.750 | 2.880 | 3.560 | 4.120 | 4 | 0.750 | 5.500 | 4.11 |

| 177.8 | 62.70 | 22.40 | 69.85 | 73.15 | 90.40 | 104.6 | 19.10 | 139.7 | |||

| 3 | 7.500 | 3.070 | 0.940 | 2.750 | 3.500 | 4.250 | 5.000 | 4 | 0.750 | 6.000 | 4.92 |

| 190.5 | 78.00 | 23.90 | 69.85 | 88.90 | 108.0 | 127.0 | 19.10 | 152.4 | |||

| 3-1/2 | 8.500 | 3.550 | 0.940 | 2.810 | 4.000 | 4.810 | 5.500 | 8 | 0.750 | 7.000 | 6.08 |

| 215.9 | 90.20 | 23.90 | 71.40 | 101.6 | 122.2 | 139.7 | 19.10 | 177.8 | |||

| 4 | 9.000 | 4.030 | 0.940 | 3.000 | 4.500 | 5.310 | 6.190 | 8 | 0.750 | 7.500 | 6.84 |

| 228.6 | 102.4 | 23.90 | 76.20 | 114.3 | 134.9 | 157.2 | 19.10 | 190.5 | |||

| 5 | 10.00 | 5.050 | 0.940 | 3.500 | 5.560 | 6.440 | 7.310 | 8 | 0.880 | 8.500 | 8.56 |

| 254.0 | 128.3 | 23.90 | 88.90 | 141.2 | 163.6 | 185.7 | 22.40 | 215.9 | |||

| 6 | 11.00 | 6.070 | 1.000 | 3.500 | 6.630 | 7.560 | 8.500 | 8 | 0.880 | 9.500 | 10.6 |

| 279.4 | 154.2 | 25.4 | 88.90 | 168.4 | 192.0 | 215.9 | 22.40 | 241.3 | |||

| 8 | 13.50 | 7.980 | 1.120 | 4.000 | 8.630 | 9.690 | 10.62 | 8 | 0.880 | 11.75 | 17.6 |

| 342.9 | 202.7 | 28.40 | 101.6 | 219.2 | 246.1 | 269.7 | 22.40 | 298.5 | |||

| 10 | 16.00 | 10.02 | 1.190 | 4.000 | 10.75 | 12.00 | 12.75 | 12 | 1.000 | 14.25 | 24.0 |

| 406.4 | 254.5 | 30.20 | 101.6 | 273.0 | 304.8 | 323.8 | 25.40 | 362.0 | |||

| 12 | 19.00 | 12.00 | 1.250 | 4.500 | 12.75 | 14.38 | 15.00 | 12 | 1.000 | 17.00 | 36.5 |

| 482.6 | 304.8 | 31.75 | 114.3 | 323.8 | 365.3 | 381.0 | 25.40 | 431.8 | |||

| 14 | 21.00 | 1.380 | 5.000 | 14.00 | 15.75 | 16.25 | 12 | 1.120 | 18.75 | 48.4 | |

| 533.4 | 35.10 | 127.0 | 355.6 | 400.1 | 412.7 | 28.40 | 476.3 | ||||

| 16 | 23.50 | 1.440 | 5.000 | 16.00 | 18.00 | 18.50 | 16 | 1.120 | 21.25 | 60.6 | |

| 596.9 | 36.60 | 127.0 | 406.4 | 475.2 | 469.9 | 28.40 | 539.8 | ||||

| 18 | 25.00 | 1.560 | 5.500 | 18.00 | 19.88 | 21.00 | 16 | 1.250 | 22.75 | 68.3 | |

| 635.0 | 39.60 | 139.7 | 457.2 | 505.0 | 533.4 | 31.75 | 577.9 | ||||

| 20 | 27.50 | 1.690 | 5.690 | 20.00 | 22.00 | 23.00 | 20 | 1.250 | 25.00 | 84.5 | |

| 698.5 | 42.90 | 144.5 | 508.0 | 558.8 | 584.2 | 31.75 | 635 | ||||

| 24 | 32.00 | 1.880 | 6.000 | 24.00 | 26.12 | 27.25 | 20 | 1.380 | 29.50 | 115 | |

| 812.8 | 47.80 | 152.4 | 609.6 | 663.4 | 692.1 | 35.10 | 749.3 |

⬇️ Download Dimension of Weld Neck flanges Class 150 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 300 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 400 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 600 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 900 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 1500 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 2500 lbs ASME B16.5 PDF

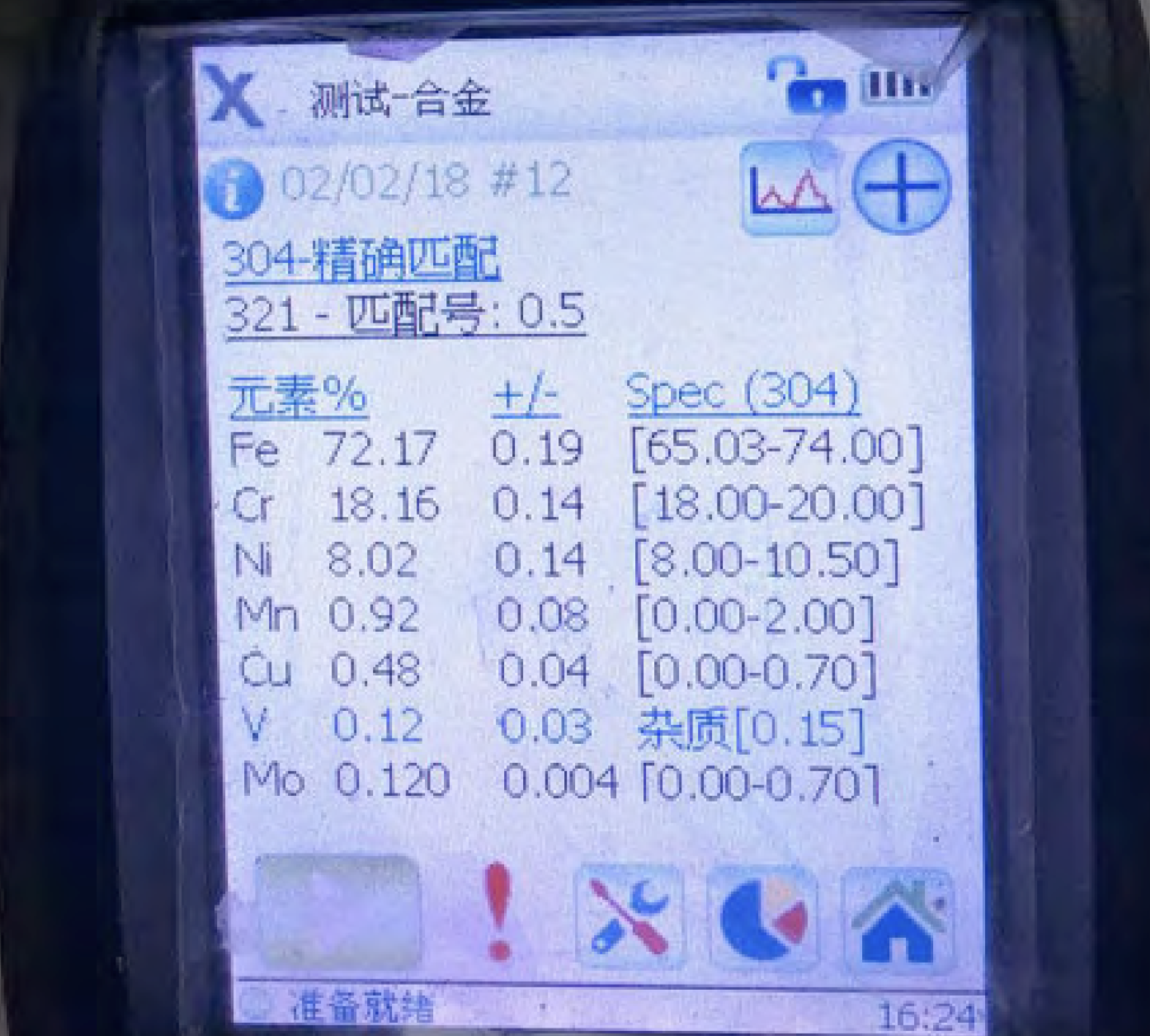

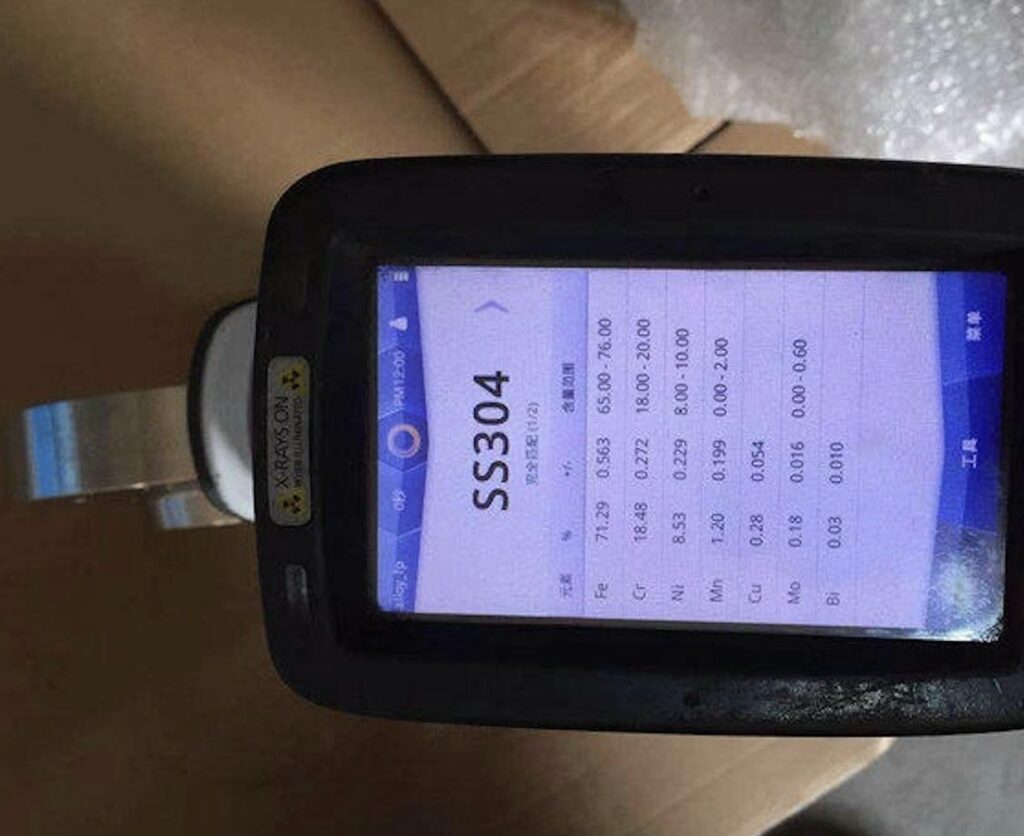

Testing & Certification of A182 F304/304L flanges

Third-party inspection: SGS, BV, TUV available

100% PMI (Positive Material Identification)

Hydrostatic Pressure Testing

UT / RT / PT / MPT as per customer request

EN 10204 3.1 / 3.2 MTC provided

A182 304/304L flanges Marking Requirements

Each flange is marked with:

- ASTM A182

- Grade ( F304/304L)

- Heat number

- Pressure rating (e.g., 300#)

- Manufacturer’s logo

- Size and schedule

Looking for a reliable ASTM A182 F304 / F304L flange supplier?

Typical Order Description of ASTM A182 F304 Weld neck Flanges

Product Name: Stainless Steel A182 F304 Weld Neck Flange

Type: Weld Neck Flange

Standard: ANSI B16.5

Material: Stainless Steel, ASTM A182 F304, SS 304

Size: 4 Inch, DN100

Pressure: Class 300 LB, PN50

Process Method: Forged

Face: Raised Face

Conact us to know more about our ASTM A182 F304 / F304L flange pricing,delivery..etc

⬇️ Download ASTM A182 F304-304L Forging specification PDF

Related Duplex Stainless Steel Flange products

- ASTM A182 F51 Weld neck flange

- ASTM A182 F53 Weld neck Flange

- ASTM A182 F304 Blind Flange