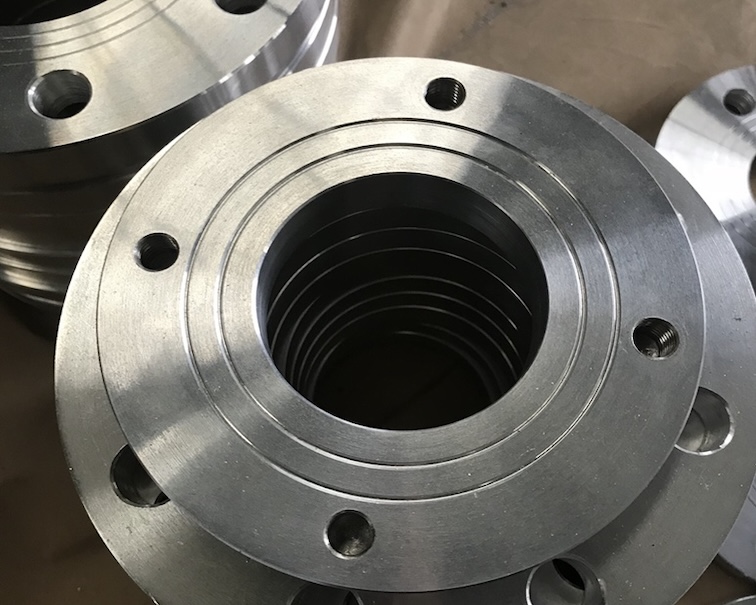

ASTM A182 F53 Weld neck Flanges Manufacturer

We are a trusted manufacturer and exporter of ASTM A182 F53 Weld Neck Flanges, offering premium-quality duplex stainless steel flanges for various industrial applications. Our products are manufactured in compliance with international standards including ASME B16.5, ASME B16.47, and EN 1092-1.

What is ASTM A182 F53 Weld Neck Flange?

ASTM A182 F53 (UNS S32750) flanges are an excellent choice for desalination plants, particularly in seawater handling and high-chloride environments.ASTM A182 Grade F53, also known as UNS S32750 or Alloy 2507, is a super duplex stainless steel renowned for its exceptional strength and outstanding corrosion resistance, particularly in chloride-rich environments like seawater, brine, and chemical processing.

Equivalent grade of ASTM A182 F53

- F53 (ASTM grade designation)

- UNS S32750 (Unified Numbering System)

- Alloy 2507 (Commercial name by Sandvik and others)

- 1.4410 (EN/DIN designation)

Why A182 F53 Flanges ?

Key Characteristics:

| Property | Description |

|---|---|

| PREN > 40 | Excellent pitting resistance in chloride environments |

| High strength | Yield strength ~2× higher than 316L |

| Cr + Mo + N + Ni | Synergistic alloying for strong corrosion and SSC resistance |

| Low thermal expansion | Good for heat exchangers and desalination systems |

| Excellent weldability | Can be fabricated with proper procedure (heat input control) |

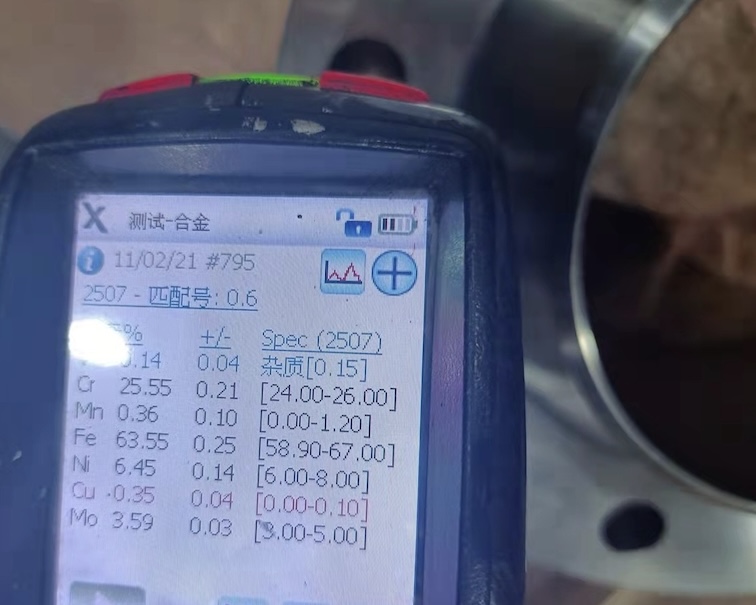

ASTM A182 F53 Chemical Compostion

| Chemical Composition Limits | ||||||||||

| Weight% | C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu |

| Super Duplex F53 | 0.03 max | 1.2 max | 0.035 max | 0.015 max | 0.8 max | 24-26 | 6-8 | 3-5 | 0.3 | 0.5 max |

ASTM A182 F53 heat treatment requirement

| Grade | Heat Treat Type | Austenitizing/Solutioning Temperature, min °F (°C)<sup>A</sup> | Cooling Media | Quenching Cool Below °F (°C) | Tempering Temperature min °F (°C) |

| F 53 | solution treat and quench | 1880 [1025] | liquid | 500 [260] | — |

ASTM A182 F53 Tensile Test and Hardness requirement

| Grade Symbol | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa]<sup>^</sup> | Elongation in 2 in. [50 mm] or 4D, min, % | Reduction of Area, min, % | Brinell Hardness Number |

| F 53 | 116 [800] | 80 [550] | 15 | – | 310 max |

A182 F53 Super Duplex Flange Specification

Material: ASTM A182 Grade F53

UNS Number: S32750

Common Type: Weld Neck, Slip-On, Blind, Lap Joint Flanges

Standards: ASME B16.5 / B16.47 / EN 1092-1

Dimensions and Standards

| Feature | Specification |

|---|---|

| Size Range | ½” to 60” (DN15–DN1500) |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Standard Compliance | ASME B16.5, B16.47, MSS SP-44, EN 1092-1 |

| Facing Options | RF (Raised Face), RTJ (Ring Type Joint), FF (Flat Face) |

| Tolerances | As per ASME B16.5 / EN 1092-1 |

Typical ITP inspection and test plan for ASTM A182 F53 flanges

| No | Activity / Description | Reference Standard | Inspection Type | Acceptance Criteria | Document Required |

| 1 | Material Inspection | ASTM A182, EN 10204 | Visual / MTC Review | Chemical & Mechanical as per ASTM A182 GR. F53 | Mill Test Certificate |

| 2 | Forging Process | In-house Standard | In-process | As per drawing & process control | |

| 3 | Heat Treatment (if required) | Internal / ASTM A991 | Review / Witness | As per WPS / PQR | HT Record |

| 4 | Machining | ASME B16.5 / Drawing | In-process | ASME B16.5 / Drawing | |

| 5 | Chemical Test | ASTM A182 | Review / Witness | ASTM A182 F53 | Chemical Test Report |

| 6 | Machanical Test | ASTM A370 | Review / Witness | ASTM A182 F53 | Machanical Test Report |

| 7 | Dimensional Inspection | ASME B16.5 / Drawing | Measurement | Tolerance per standard | Dimensional Report |

| 8 | NDT – UT / PT (if applicable) | ASME Sec V / Client Spec | Witness / Review | ASME | NDT Reports |

| 9 | Marking & Stamping | ASTM A182 / Project Spec | Visual | As per code | Marking Photo |

| 10 | Packing & Preservation | Internal Procedure | Visual | Export-worthy packaging, corrosion protection | Packing List / Photos |

| 11 | MTC | EN10204 3.1 /3.2 | Final | All docs submitted & approved |

Order Specification for ASTM A182 F53 Weld Neck Flanges

1. Product: Weld Neck Flanges

2. Material Grade: ASTM A182 F53 (UNS S32750, Super Duplex Stainless Steel)

3. Flange Type: Weld Neck (WN)

4. Design Standard: ASME B16.5 (for sizes ≤ 24″) or ASME B16.47 (for sizes > 24″)

5. Pressure Rating: [Class 150 / 300 / 600 / 900 / 1500 / 2500] (specify as required)

6. Size Range: [e.g., 2″ NB to 24″ NB]

7. Face Type: Raised Face (RF) / Ring Type Joint (RTJ) / Flat Face (FF)

8. Facing Finish: 125–250 AARH serrated finish (default)

Download the Dimension of ASME B16.5 Weld neck Flange

⬇️ Download Dimension of Weld Neck flanges Class 150 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 300 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 400 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 600 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 900 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 1500 lbs ASME B16.5 PDF

⬇️ Download Dimension of Weld Neck flanges Class 2500 lbs ASME B16.5 PDF

ASTM A182 F53 vs F51 Flanges

| Item | F53 (S32750) | F51 (S31803 / S32205) |

|---|---|---|

| Corrosion Resistance | Excellent | Very Good |

| Yield Strength | Higher | Lower |

| Seawater Service | Excellent | Limited |

| Typical Use | Offshore / subsea | General duplex |

ASTM A182 F53 weld neck flanges (UNS S32750) provide superior strength, corrosion resistance, and long-term reliability for the most demanding piping systems. Fully compliant with ASTM A182 and ASME flange standards, super duplex F53 flanges are the preferred solution for offshore, desalination, and high-pressure applications.