ASTM A182 F9 Flanges Manufacturer

We are a leading ASTM A182 F9 Flanges manufacturer in China, offering a wide range of high-performance forged alloy steel flanges for critical piping systems. Made from chromium-molybdenum alloy steel (9Cr-1Mo), ASTM A182 F9 flanges are widely used in high-temperature and high-pressure environments such as power plants, refineries, and petrochemical industries.

All our flanges are manufactured in accordance with ASME B16.5, B16.47, and EN/DIN standards, with full traceability, heat treatment, and 3.1 certification.

What is ASTM A182 F9?

ASTM A182 / A182M – Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, Valves and Parts for High-Temperature Service

F9 refers to a forged material grade with 9 % Cr

ASTM A182 F9 is a forging material grade of so-called “9-Chrome 1-Moly” material ,the same grade with the piping grade ASTM A335 P9 Seamless Pipes,and ASTM A234 WP9 for Pipe fittings.

ASTM A182 F9 Chemical Compostion

| Elements | A182 F9 |

| Carbon | 0.150 |

| Manganese | 0.30-0.60 |

| Phosphorus | 0.030 |

| Sulfur | 0.030 |

| Silicon | 0.50-1.00 |

| Nickel | … |

| Chromium | 8.0-10.0 |

| Molybdenum | 0.90-1.10 |

ASTM A182 F9 Mechanical Properties and Hardness requirement

Tensile and Hardness Requirements

| Grade | A 182 F9 |

| Tensile Strength,min, ksi [Mpa] | 85[585] |

| Yield Strength, min,ksi [MPa] | 55[380] |

| Elongation in 2 in.[50 mm] or 4D,min, % | 20 |

| Reduction of Area, min, % | 40 |

| Brinell HardnessNumber | 179-217 |

ASTM A182 F9 Weld neck Flanges Specifications

- Standard: ASTM A182 / ASME SA182

- Flange type:Weld Neck Flanges

- Material Grade: F9 (9Cr-1Mo alloy steel)

- Heat Treatment: Normalized & Tempered or Annealed

- Standards: ASME B16.5, ASME B16.47, MSS-SP-44

- Size:1/2″ to 60″

- Class:150lbs to 2500lbs

- Certification: Mill Test Certificates (EN 10204 3.1 / 3.2)

Other Flange type available:Slip-On (SO) Flanges / Blind (BL) Flanges/ Socket Weld (SW) Flanges /Long Weld Neck (LWN) Flanges

ASTM A182 F9 Heat Treatment

After hot working, forgings must be cooled to a temperature below 1000∘F(538∘C) before heat treatment

ASTM A182 requires that all F9 components be heat treated after final forging to ensure proper mechanical properties for high-temperature and high-pressure applications.

Annealing

Normalized and Tempered (N+T)

ASTM A182 F9 FlangesTesting Requirements

Mandatory Tests (per ASTM A182 & A961):

- Chemical Analysis

- Heat analysis for every heat of steel

- Product (check) analysis may be required

- Mechanical Testing

- Tensile Test

- Required for each heat

- Hardness Test

- Typical range 187–235 HBW

- Tensile Test

- Visual and Dimensional Inspection

- Mandatory per ASME/ANSI flange standards

- NDT Optional – per project or client requirement

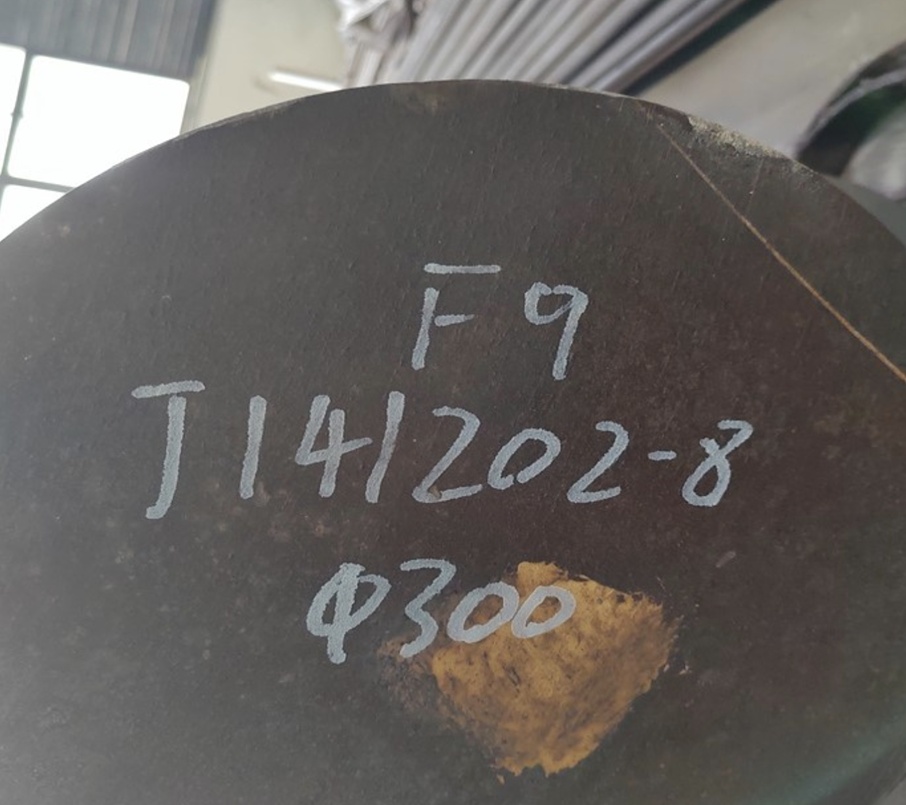

ASTM A182 F9 Flanges are made of F9 round bar

Looking for ASTM A182 F9 alloy steel flanges at competitive prices?

| item | Description of flanges | unit | quantity |

| 1 | FLANGE 2″ ASME CLASS 600, A182-F9, WN, RF- SERR, SCH 160 | PC | 15 |

| 2 | FLANGE 4″ ASME CLASS 600, A182-F9, WN, RF- SERR, SCH 120 | PC | 8 |

| 3 | FLANGE 3″ ASME CLASS 300, A182-F9, WN, RF- SERR, SCH 160 | PC | 12 |