ASTM B564 UNS N06625 Inconel 625 Weld Neck Flanges ,Blind FlangesManufacturer

We are a trusted manufacturer and global supplier of ASTM B564 UNS N06625 Flanges, also known as Inconel 625 flanges. We offer a complete range of forged flanges in this high-performance nickel-chromium-molybdenum alloy, designed for extreme environments involving high temperatures and aggressive corrosion.

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures.

Alloy 625 has excellent corrosion resistance and oxidation resistance, good tensile properties and fatigue properties from low temperature to 980°C, and resistance to stress corrosion under salt spray atmosphere. Therefore, it can be widely used in the manufacture of aero engine parts, aerospace structural components and chemical equipment and applications that are exposed to seawater and withstand high mechanical stress.

N06625 Flanges are made of Inconel 625 round bar,via forging and machining process.

ASTM B564 N06625 Flange Standard & Material Designation

| Standard | Details |

|---|---|

| ASTM B564 | Standard for forged fittings/flanges of nickel alloy materials |

| Alloy Designation | N06625 = Inconel® 625 (nickel-chromium-molybdenum-niobium alloy) |

| UNS Number | N06625 |

| Common Name | Inconel 625,Alloy 625 |

Standard Compliance: ASTM B564 / ASME SB564

Size Range: ½″ to 48″ (15NB to 1200NB)

Pressure Ratings: Class 150 to 2500; PN 2.5 to PN 400

Chemical Composition of Alloy 625 (N06625)

| Element | % Composition |

|---|---|

| Nickel (Ni) | ≥ 58.0 (Balance) |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium (Nb) + Ta | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Cobalt (Co) | ≤ 1.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

UNS N06625 Mechanical Property Requirements According to ASTM B564

| Material and Condition | Maximum Section Thickness, in. (mm) | Tensile Strength, min, ksi (MPa) | Yield Strength, 0.2% Offset, min, ksi (MPa) | Elongation in 2 in. or 50 mm or 4D, min, % | |

| Nickel-chromium-molybdenum-columbium alloy UNS N06625, annealed | Up to 4 (102), incl | 120 (827) | 60 (414) | 30 | |

| Over 4<sup>B</sup> (102) to 10 (254), incl | 110 (758) | 50 (345) | 25 |

our Inconel Weld neck flange can be Manufactured per ASME B16.5, B16.47, or MSS-SP-44:

Other Flange Types Available:Blind flange,Slip on Flange,Blind Flanges

Heat Treatment of B564 N06625 Flanges

- Annealing temperature: ~980–1038°C (1800–1900°F), air or rapid quench

- Material is typically solution annealed before final machining

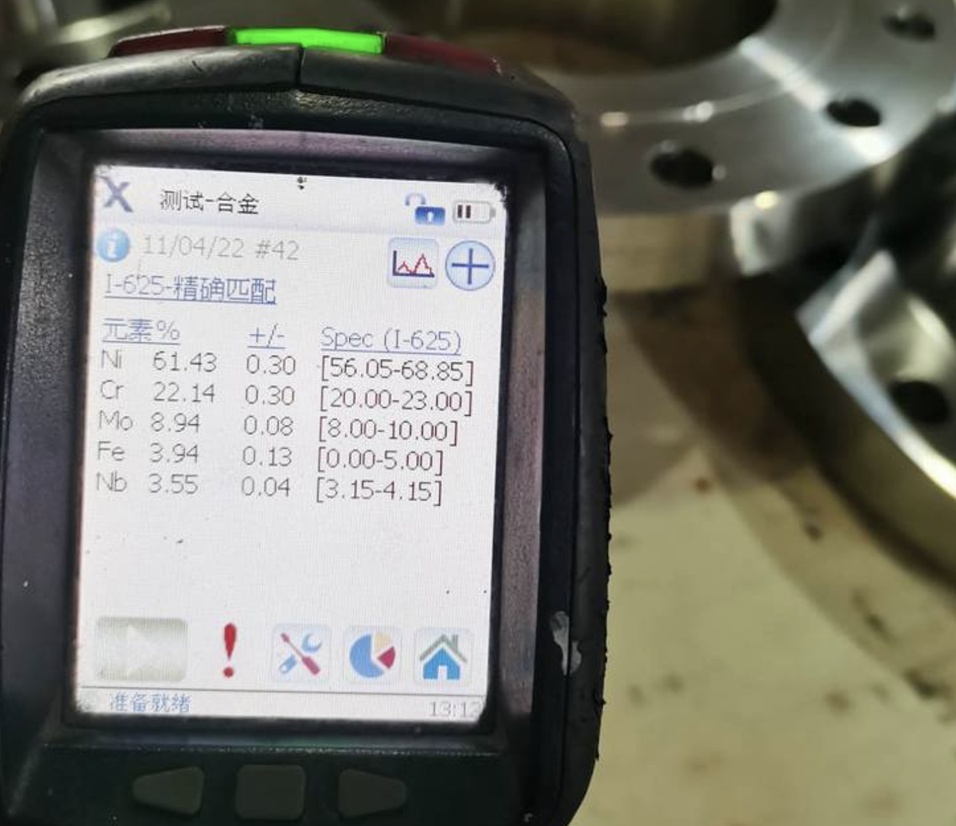

Standard Testing Requirements for ASTM B564 UNS N06625 Flanges

According to the ASTM B564 specification, the following tests are mandated for UNS N06625 flanges:

1. Chemical Composition Analysis

2. Mechanical Testing

3. Ultrasonic Testing

4.Visual and Dimension

Certification and Documentation

Manufacturers typically provide a Material Test Certificate (MTC) in accordance with EN 10204 3.1 or 3.2, detailing the results of the aforementioned tests. This documentation serves as a testament to the flange’s compliance with ASTM B564 standards and is often required for quality assurance and regulatory purposes.

ASTM B564 N06625 Flanges Ordering Information

When specifying ASTM B564 UNS N06625 flanges, please provide:

- Size & Pressure Rating: e.g., 2″ Class 300

- Flange Type: ASTM B564 N06625 Weld Neck flange, ASTM B564 N06625 Slip on flange, ASTM B564 N06625 Blind flanges, etc.

- Facing Type: RF, FF, RTJ

- Standard Compliance: ASTM B564 / ASME SB564

- Testing Requirements: e.g., PMI, UT, MTC as per EN 10204 3.1 or 3.2

Download ASTM B564 Inconel 625 N06625 Flanges specification

As an experienced ASTM B564 UNS N06625 Weld Neck Flange manufacturer, we provide high-quality, durable, and reliable flanges for critical industrial applications. With our superior Inconel 625 material, custom manufacturing options, and commitment to quality, we are your trusted partner for weld neck flanges. Whether you are in oil & gas, aerospace, chemical processing, or power generation, our ASTM B564 UNS N06625 flanges ensure the performance and longevity of your piping systems.

Contact us today to discuss your ASTM B564 UNS N06625 Weld Neck Flange requirements