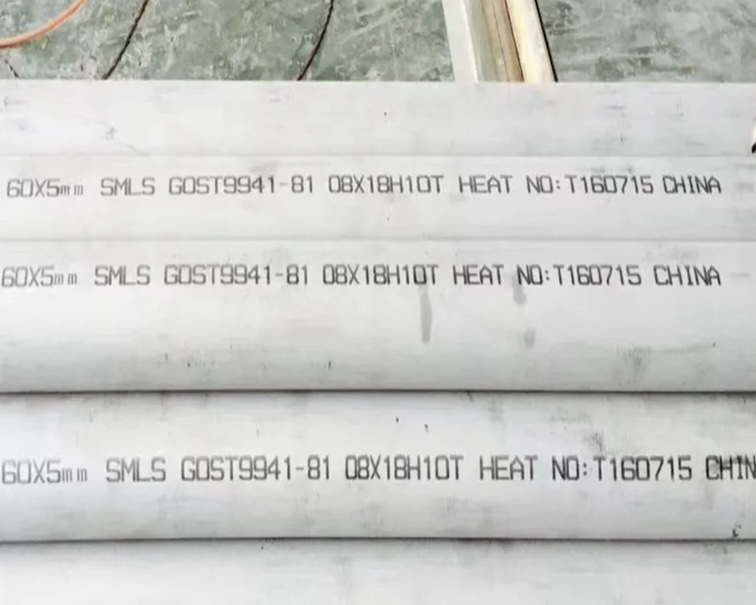

Gost 9941 08Х18Н10 Pipe Manufacturer

We are a leading manufacturer, stockist, and global exporter of GOST 9941 08Х18Н10 seamless stainless steel pipes and tubes, equivalent to AISI 304 / EN 1.4301 / UNS S30400. These pipes are widely used in petrochemical, food processing, marine, power generation, and pharmaceutical industries due to their excellent corrosion resistance, durability, and weldability.

08Х18Н10 ,08KH18N10 grade is a Gost stainless steel according to Russian standard,It is a high-quality stainless steel featuring approximately 18% chromium and 10% nickel with a low carbon content, ensuring excellent resistance against corrosion and oxidation. This composition provides outstanding mechanical strength and thermal stability, making it ideal for both standard and critical applications.

Steel 08Х18Н10 belongs to high-alloy alloys of the austenitic type. The presence of chromium, nickel and titanium in the composition determine the main advantages of the material of this grade: resistance to high temperatures and corrosion, strength

Working characteristics of steel 08Х18Н10:

- Corrosion resistance: the alloy structure is not subject to intercrystalline and atmospheric corrosion. The material is used in salts, alkalis, phosphoric, acetic and nitric acids. In sea water, steel retains its structure.

- Heat resistance: steel products are designed for use at temperatures up to 800°C, when used in aggressive chemical environments, the maximum heating temperature is 600°C. However, stainless steel grade 08X18N10 is also effective when cooled to -196°C.

- Strength: the alloy can withstand constant mechanical loads, impacts, and vibration.

- Weakly magnetic material: after heat treatment, steel is virtually non-magnetic.

- Good weldability: no restrictions, used for contact, spot welding, manual and automatic, in carbon dioxide.

- Ease of processing: used for the production of rolled metal products, steel parts and elements.

Manufactured under the GOST 9941 standard, these seamless pipes meet strict quality and performance criteria. They are designed to deliver consistent results in high-temperature, high-pressure, and aggressive chemical environments.

Manufacturing Standards

GOST 9941 covers:

- Hot-worked seamless pipes

- Cold-drawn / cold-rolled seamless pipes

Dimensional accuracy and mechanical strength depend on manufacturing method.

Related Russian standards:

- GOST 9940 – Seamless stainless steel pipes for high-temperature service

- GOST 5632 – Stainless steel and heat-resistant alloy grades

- GOST 32528 – Technical delivery conditions

Dimensional Range (as per GOST 9941):

| Parameter | Range |

|---|---|

| Outer Diameter (OD) | 15 mm to 325 mm |

| Wall Thickness | 3 mm to 20 mm (cold-rolled) |

08KH18N10 ( 08Х18Н10 ) Chemical composition

| C | Si | Mn | Ni | S | P | Cr | Ti | Cu |

| max 0.08 | max 0.8 | max 2 | 9 – 11 | max 0.02 | max 0.035 | 17 – 19 | max 0.5 | max 0.3 |

Mechanical properties 08KH18N10 ( 08Х18Н10 )

| Assortment | Dimension | Direct. | sв | sT | d5 | y | KCU | Heat treatment |

| – | mm | – | MPa | MPa | % | % | kJ / m2 | – |

| Pipe cooling strain, GOST 9941-81 | 529 | 37 | ||||||

| Pipe hot strain, GOST 9940-81 | 510 | 40 | ||||||

| Bar, GOST 5949-75 | Ø 60 | 470 | 196 | 40 | 55 | Guenching 1020 – 1100oC, |

08X18H10 Equivalent grade

| grade | Analogue | W. Nr. | Aisi Uns | En | |

|---|---|---|---|---|---|

| 08X18H10 | EI825 | 1.4301 | 304 | X5CrNi1810 |

The Russian stainless steel grade 08Х18Н10 (08Kh18N10) and the American AISI 304 are very similar and often considered equivalent in terms of chemical composition, mechanical properties, and corrosion resistance.

Want to know about ASTM A312 TP304/304L Seamless pipes?

Comparison of 08X18H10 and AISI 304

| Property | 08Х18Н10 (GOST) | AISI 304 (ASTM) |

|---|---|---|

| Standard | GOST 5632, GOST 9941 | ASTM A240, ASTM A312, etc. |

| Type | Austenitic stainless steel | Austenitic stainless steel |

| Carbon (C) | ≤ 0.08% | ≤ 0.08% (304) / ≤ 0.03% (304L) |

| Chromium (Cr) | 17.0–19.0% | 18.0–20.0% |

| Nickel (Ni) | 9–11% | 8.0–10.5% |

| Manganese (Mn) | ≤ 2.0% | ≤ 2.0% |

| Silicon (Si) | ≤ 0.8% | ≤ 1.0% |

| Phosphorus (P) | ≤ 0.035% | ≤ 0.045% |

| Sulfur (S) | ≤ 0.02% | ≤ 0.03% |

| Yield Strength | ~200 MPa | ~205 MPa |

| Tensile Strength | ≥ 500 MPa | 515–750 MPa |

| Elongation | ≥ 40% | ~40% |

| Density | ~7.9 g/cm³ | ~7.9 g/cm³ |

Advantages of 08Х18Н10 Stainless Steel Pipe:

- Outstanding Corrosion Resistance: Excellent protection against rust and corrosion, even in aggressive chemical environments.

- Heat Resistance: High-temperature resistance up to 1100°C (2012°F), making it suitable for applications involving steam, heat exchangers, and boilers.

- Long-Term Durability: Reliable in harsh industrial conditions, ensuring longevity and reduced maintenance costs.

- Weldability: This stainless steel can be easily welded using conventional methods, ensuring a strong, leak-proof system.

GOST 9941 08Х18Н10 Seamless Pipe Permissible Deviations of the wall thickness

| Steel Grade | Wall Thickness, MM | Permissible Deviation for Manufacturing Accuracy | ||

| Ordinary | Increased | High | ||

| All, except 06Х28МДТ | Less than 0.3 | ±0.05 MM | ±0.03 MM | — |

| From 0.3 to 0.4 inclusive | ±0.07 MM | ±0.05 MM | — | |

| Over 0.4 – 0.6 | ±0.10 MM | ±0.07 MM | — | |

| Over 0.6 – 1.0 | ±0.15 MM | ±0.10 MM | — | |

| Over 1.0 – 3.0 | 12.50% | 12.50% | 12.50% | |

| −15.0 % | −15.0 % | −10.0 % | ||

| Over 1.0 – 3.0 (with D/S ratio 40 and more) | ±15.0 % | 12.50% | — | |

| −15.0 % | ||||

| Over 3.0 – 7.0 (with D/S ratio less than 40) | ±12.5 % | 12.50% | ±10.0 % | |

| −10.0 % | ||||

| Over 3.0 – 7.0 (with D/S ratio 40 and more) | 12.50% | ±12.5 % | — | |

| −15.0 % | ||||

| Over 7.0 (with outer diameter less than 325 MM) | 12.50% | ±10.0 % | — | |

| −10.0 % | ||||

| Over 7.0 (with outer diameter 325 MM and more) | 12.50% | ±12.5 % | — | |

| −15.0 % |

GOST 9941 08Х18Н10 Pipes Heat Treatment:

- Pipes are typically supplied in the solution annealed condition (around 1050–1100°C), followed by water or air quenching.

GOST 9941 08Х18Н10 Pipe Testing Requirements:

- Hydrostatic or Eddy Current Testing (as required)

- Dimensional and Visual Inspection

- Chemical Composition Analysis

- Mechanical Testing (tensile, elongation, hardness)

- Optional: Intergranular corrosion test (per GOST 6032 or ASTM A262 Practice E)

As a trusted supplier of GOST 9941 08Х18Н10 / AISI 304 seamless stainless steel pipes, we provide premium quality tubes with mill test certificates (MTC), third-party inspection, and international shipping. Our seamless stainless steel pipes are exported worldwide to Europe, Middle East, Asia.

Order Example

Product: GOST 9941 08Х18Н10 Seamless Stainless Steel Pipe

OD × WT: 76 × 4 mm

Length: 6 m

Delivery Condition: Annealed (AT)

Standard: GOST 9941-81

Quantity: 3.5 tons

Testing: Hydrostatic + PMI

Certification: EN 10204 3.1

Download GOST-9941-08Х18Н10-Seamless-Stainless-Steel-Pipe specification