GOST 9941 10X17H13M2T stainless steel Pipes Manufacturer

10X17H13M2T is stainless steel grade under gost standard,It is equivalent grade of AISI 316Ti.EN 1.4571 / X6CrNiMoTi17-12-2

10X17H13M2T: increased resistance to aggressive environments with high acidity, which is not lost even when the material is thermally exposed (up to 600 degrees Celsius). This steel grade is used most of all in the chemical, food and medical industries. Pipes from this steel are enoughPrecisely easy to weld, thus obtaining a monolithic product with an extremely long service life.

10X17H13M2T was specified in GOST 5632

10X17H13M2T Chemical Composition as below

| C | Si | Mn | Ni | S | P | Cr | Mo | Cu | Ti |

| max 0.1 | max 0.8 | max 2 | 12 – 14 | max 0.02 | max 0.035 | 16 – 18 | 2 – 3 | max 0.3 | (5 С – 0.7) Ti, остальное Fe |

10X17H13M2T Mechanical Property

| Steel Grade | Yield Strength σв, H/mm² | Yield Limit σ0.2, H/mm² | Elongation δ5, % |

|---|---|---|---|

| 10X17H13M2T | 529 | 2) | 35 |

This table presents the mechanical properties at 20 °C for the metal of thermally – processed tubes with a D/S ratio less than 40. The yield strength for 10X17H13M2T is 529 H/mm², the elongation δ5 is 35%, and the yield limit σ0.2 has a note

“2)” with no specific value provided in the original data.

10X17H13M2T Steel Density

| Steel Grade | Steel Density, g/cm³ |

|---|---|

| 10X17H13M2T | 8.00 |

GOST 9941 2022

Download GOST 9941 pdf

GOST 9941-2022 is a Russian industry standard that specifies the requirements for alloy steel seamless warm-deformed tubes used in corrosion-resistant

Application:

- Seamless pipes made of austenitic, ferritic, and ferritic-austenitic (duplex) stainless steels.

- For use in high-temperature, corrosive, and pressure applications.

GOST 9941 Pipe Specification

Dimensional Specification

| Property | Range |

|---|---|

| Outer Diameter (OD) | 6 mm to 273 mm |

| Wall Thickness | 0.5 mm to 22 mm |

| Length | Random (4–8 m), fixed, or multiple lengths |

GOST 9941 10X17H13M2T Heat Treatment

- Pipes are usually delivered in solution-annealed condition.

Testing & Inspection Requirements

| Test Type | Description |

|---|---|

| Hydrostatic Test | Mandatory for pressure service |

| NDT (Eddy current/Ultrasonic) | On request or per agreement |

| Mechanical Testing | Tensile, hardness, elongation |

| Visual & Dimensional Check | To ensure surface & size conformity |

| Chemical Analysis | Confirms alloy composition |

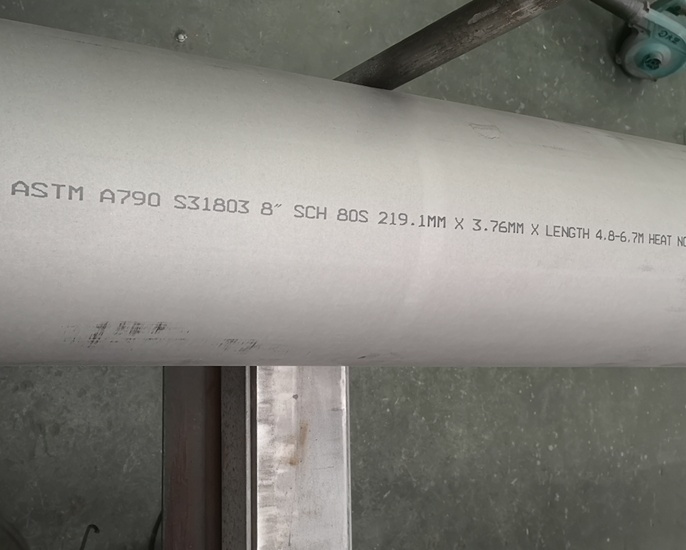

Marking & Documentation

Each pipe is marked as blow

- Steel grade

- Pipe size (OD × WT)

- Heat or batch number

- Standard: GOST 9941

- Manufacturer’s logo or name