Inconel 718 (UNS N07718) Stud Bolts & Hex Nuts – Manufacturer & Supplier

We are a leading manufacturer and global supplier of Inconel 718 Stud Bolts and Hex Nuts (UNS N07718) for high-temperature, high-pressure, and extreme corrosion environments.

Inconel 718 is a nickel-chromium alloy strengthened by niobium and molybdenum, providing outstanding mechanical properties up to 700°C (1300°F) and excellent resistance to oxidation, crevice corrosion, and stress-corrosion cracking.

Inconel 718 fasteners are widely used in aerospace, gas turbines, oil & gas, chemical processing, nuclear power, downhole tools, and cryogenic applications.

What Is Inconel 718 Stud Bolt?

Inconel 718 is a nickel-chromium alloy with high strength and excellent corrosion resistance, especially at temperatures up to 700°C (1300°F). It’s widely used in aerospace, power generation, oil & gas, and chemical processing industries.

Alloy 718 (UNS N07718, W Nr 2.4668) is a high-strength, heat-resistant and corrosion-resistant nickel-based alloy composed of nickel, chromium, molybdenum, iron, aluminum, titanium and niobium. Due to its excellent properties, high yield tensile and creep-rupture properties at temperatures up to 1300ºF and oxidation resistance to 1800ºF. This alloy has a wide range of applications in aerospace, energy, automotive manufacturing and chemical industries

Chemical Composition of N07718 Bolt

| Inconel 718 Chemical Composition | ||||||||||||||||

| Weight % | C | Mn | P | S | Si | Cr | Ni | Mo | Cb | Ta | Ti | Al | Co | B | Cu | Fe |

| Alloy 718 AMS 5662 | 0.08 | 0.35 | 0.015 | 0.015 | 0.35 | 17-21 | 50-55 | 2.8-3.30 | 4.75-5.50 | 0.05 | 0.65-1.15 | 0.20-0.80 | 1.00 | 0.006 | 0.30 | Rem |

N07718 Bolt Specifications:

| Parameter | Value / Spec |

|---|---|

| Material | Inconel 718 (UNS N07718) |

| Standards | ASTM B637, AMS 5662 / 5663 / 5664,API 6ACRA |

| Forms | Stud bolts, hex bolts, threaded rods |

| Heat Treatment | Typically solution treated & aged |

| Threads | UNC/UNF, metric, |

Size Range

Stud Bolts

- Diameter: M6 – M72 or ¼” – 3″

- Length: up to 3000 mm

- Thread: UNC / UNF / Metric / BSW

- Tolerance: ASME B1.1 / B1.13M

Hex Nuts

- Sizes: M6 – M72 or ¼” – 3″

- Grade: Inconel 718, age hardened

- Standard: ASME B18.2.2 / DIN 934 / DIN 6915

We can supply the N07718 stud bolt according to Both B637 and API 6ACRA standard

This specification covers hot- and cold-worked precipitation-hardenable nickel alloy rod, bar, forgings, and forging stock for high-temperature service

Age-hardened Nickel-based Alloys for Oil and Gas Drilling and Production Equipment

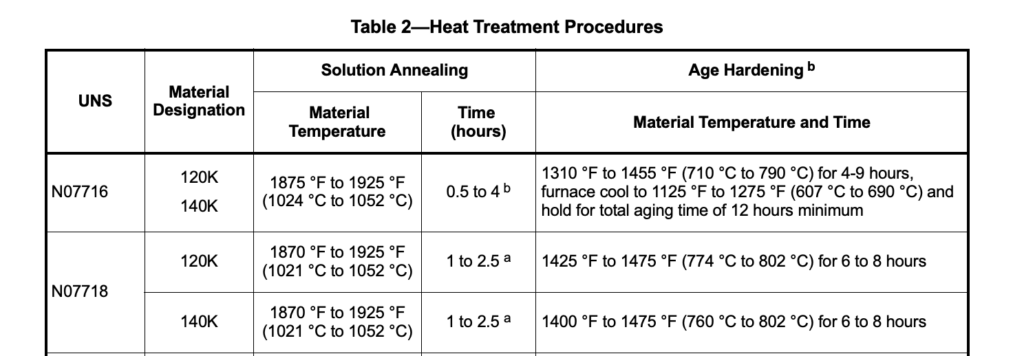

N07718 heat treatment under API 6ACRA

| UNS | Material Designation | Solution Annealing | Age Hardening<sup>b</sup> | |

| Material Temperature | Time (hours) | Material Temperature and Time | ||

| N07718 | 120K | 1870 °F to 1925 °F (1021 °C to 1052 °C) | 1 to 2.5 | 1425 °F to 1475 °F (774 °C to 802 °C) for 6 to 8 hours |

| 140K | 1870 °F to 1925 °F (1021 °C to 1052 °C) | 1 to 2.5 | 1400 °F to 1475 °F (760 °C to 802 °C) for 6 to 8 hours |

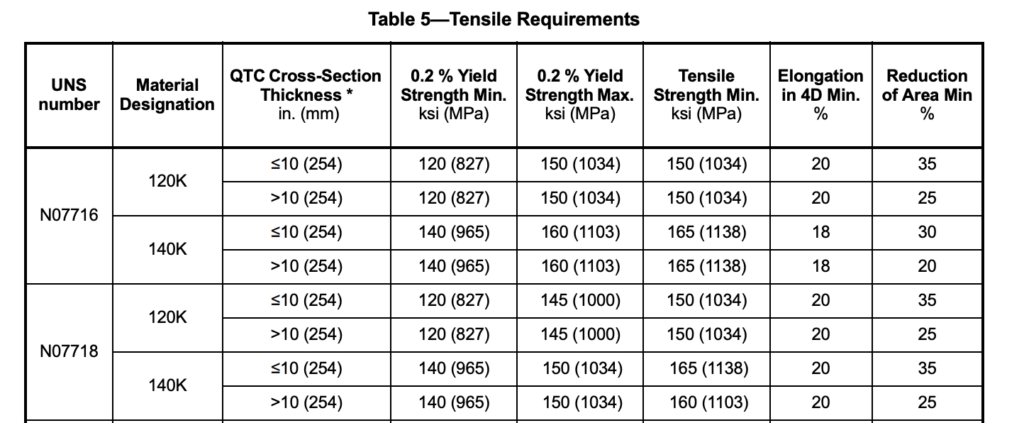

N07718 Tensile requirements under API 6ACRA

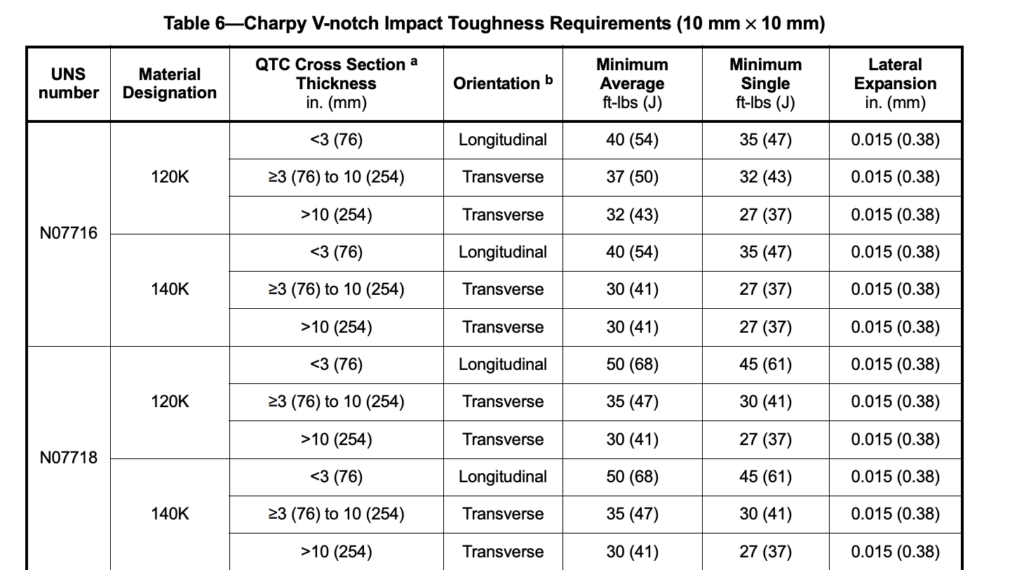

Charpy V-notch Impact Toughness Requirements for N07718 (10 mm × 10 mm)

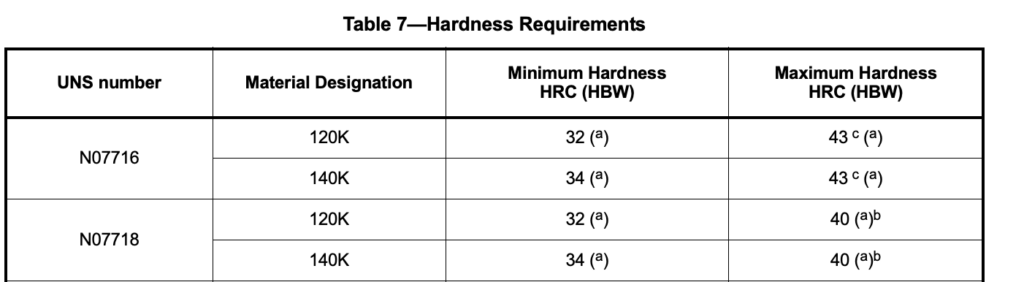

Hardness of N07718

A typical description of N07718 stud bolt

Product Name: Nickel Alloy Stud Bolt

Standard: ISO 261

Material: ASTM B637 UNS N07718

Size: M32X300MM

Length: 320 MM

Stud Bolt with 2 N07718 Nuts

Heat Treatment: Solid Solution 1000℃ and Precipitation Hardening 720℃

Application: for High Temperature Service

Global Supply & Export

We supply Inconel 718 stud bolts to Europe, Middle East, USA, Korea, and Southeast Asia, supporting EPC contractors, refineries, and OEMs with bulk quantities, third-party inspection, and mill test certificates (EN 10204 3.1 / 3.2).

Request a Quote for Inconel 718 fasteners

Send us your inquiry for Inconel 718 stud bolts, including specifications, drawings, and quantity. We guarantee competitive prices, timely delivery, and certified quality.