Stainless Steel 904L Flanges | ASTM A182 UNS N08904 Flanges Manufacturer

As a trusted manufacturer and global supplier of high-performance ASTM A182 904L flanges, we offer forged flanges in a variety of types, sizes, and pressure ratings. Our 904L stainless steel flanges are engineered for exceptional corrosion resistance, particularly in aggressive chemical and marine environments.

UNS N08904: known as AISI 904L,1.4539, which a super austenitic stainless steel with:

- High nickel (23–28%)

- High molybdenum (4–5%)

- Added copper (1–2%) for resistance to sulfuric acid

904L is an austenitic stainless steel. and its molybdenum addition gives it superior resistance to localized attack (pitting and crevice corrosion) by chlorides and greater resistance reducing acids.

| Material No. | EN Designation | AISI/SAE | UNS |

|---|---|---|---|

| 1.4539 | X1NiCrMoCu25 – 20 – 5 | 904 L | N08904 |

Character of SS904L

| Excellent corrosion resistance to sulfuric and phosphoric conditions. High resistance to localized corrosion such as pitting and crevice corrosion, as well as to stress-corrosion. |

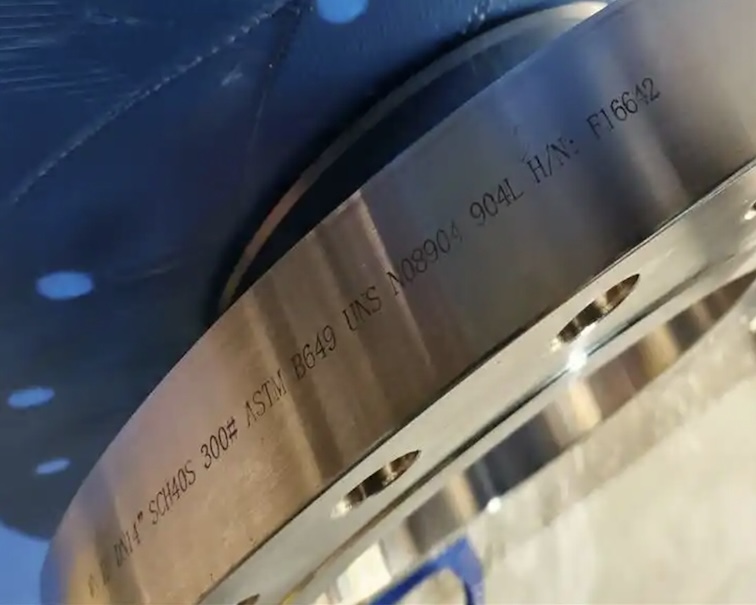

F904L flanges are the forged 904L grade according to ASTM A182 standard ,which is the Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service.

Flanges in UNS N08904 are typically supplied in the following types:

- 904L Welding Neck Flange (WN)

- 904L Slip-On Flange (SO)

- 904L Socket Weld (SW)

- 904L Blind Flange (BL)

- Threaded (TH)

- Lap Joint (LJ)

These are manufactured according to:

- ASME B16.5 (for sizes DN 15–DN 600)

- ASME B16.47 (for larger diameters)

- Optionally MSS-SP-44 or API 605

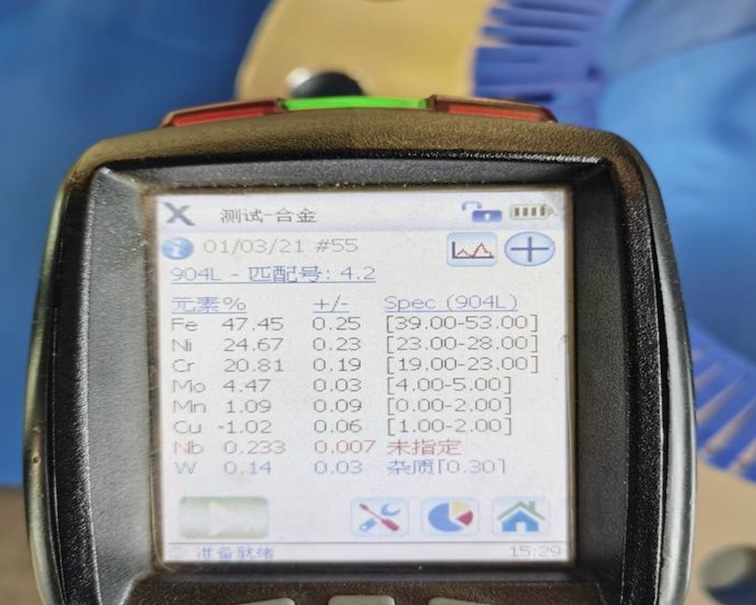

Composition of 904L according to ASTM A182

Chemical Requirements

| Grade/Identification Symbol | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum | Niobium⁸ | Titanium | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F 904L | N08904 | 0.020 | 2.0 | 0.040 | 0.030 | 1.00 | 23.0 – 28.0 | 19.0 – 23.0 | 4.0 – 5.0 | … | … | Cu 1.00 – 2.00 N 0.10 |

Heat Treat Requirements

| Grade | Heat Treat Type | Austenitizing/Solutioning Temperature, Minimum or Range, °F [°C]⁴ | Cooling Media | Quenching Cool Below °F [°C] | Tempering Temperature, Minimum or Range, °F [°C] |

|---|---|---|---|---|---|

| F 904L | solution treat and quench | 1920 – 2100 [1050 – 1150] | liquidᴱ | 500 [260] | ᴮ |

| Grade Symbol | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa]⁸ | Elongation in 2 in. [50 mm] or 4D, min, % | Reduction of Area, min, % | Brinell Hardness Number, HBW, unless otherwise indicated |

|---|---|---|---|---|---|

| F 904L | 71 [490] | 31 [215] | 35 | … | … |

Test Requirements for ASTM A182 UNS N08904 Flanges

To ensure the quality of 904L flanges,following test will be conducted during final inspection.

1. Chemical Composition Test

2. Mechanical Tests

3. Intergranular Corrosion (IGC) Test (if specified)

4. Visual & Dimensional Inspection

- Check for:

- Surface finish (free of scale, pitting, cracks)

- Dimensional tolerances (per ASME B16.5 or B16.47)

5. Non-Destructive Testing (NDT) (as per purchase spec)

| Test | Standard | Purpose |

| Dye Penetrant (PT) | ASTM E165 | Detect surface cracks |

| Ultrasonic (UT) | ASTM A388 | Detect internal flaws |

6. Documentation Requirements

- MTC: EN 10204 3.1 or 3.2

Purchase Description

ASTM A182 F904L (UNS N08904) Weld Neck Flange, 6″ NB, Class 300, RF Face, ASME B16.5, Solution Annealed, MTC EN 10204 3.1, NACE MR0175 Compliant.”

Would you be interested in ?Pls contact us freely.

- A sample MTC for ASTM A182 904L flanges?

- Price for your ASTM A182 F904L flange request?

⬇️ Download N08904 Specification Now (PDF)

⬇️ Download ASTM A182 904L Specification Now (PDF)

Related Products of 904L

| Seamless Pipe ASTM B677 UNS N08904 |

| Butt-Weld Pipe Fittings (ASTM A403 WP904L) Elbows (90°/45°) |