Guidance of ASTM A105 Specification

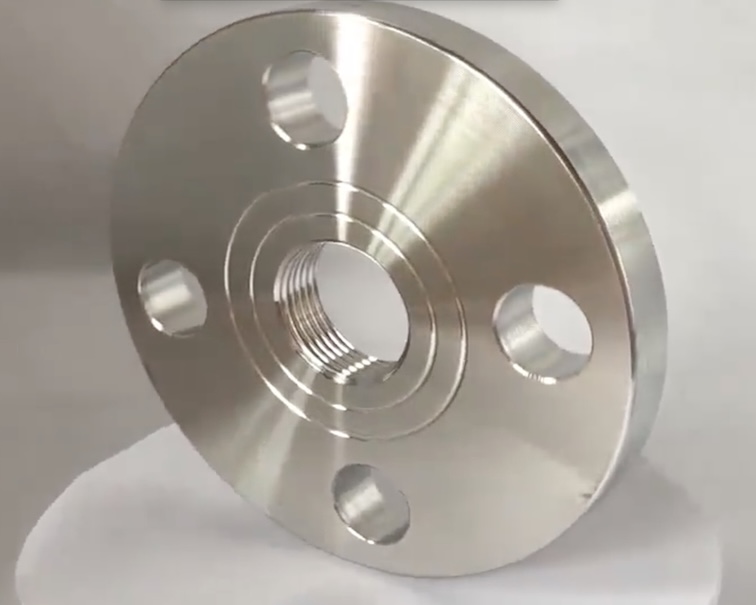

ASTM A105 covers forgings for piping components such as flanges, fittings, valves, and similar parts for high-temperature service.

It is most commonly used for:

- Pipe flanges

- Forged fittings

- Valves

- Other pressure parts

History of ASTM A105 Standard

| Edition Year | Designation | Description / Note |

| 1949 | ASTM A105 | First issued as standard specification for carbon steel forgings for piping parts. |

| 1976 | ASTM A105-76 | Major update with clarified mechanical and chemical requirements. |

| 1987 | ASTM A105-87 | Reaffirmation with minor editorial changes. |

| 1993 | ASTM A105/A105M-93 | Dual-unit (inch and metric) edition introduced. |

| 2000 | ASTM A105/A105M-00 | Includes dimensional tolerance clarifications. |

| 2005 | ASTM A105/A105M-05 | Revised to reflect updated mechanical testing protocols. |

| 2006 | ASTM A105/A105M-06 | Minor changes and reaffirmation. |

| 2010 | ASTM A105/A105M-10 | Minor technical edits and updates. |

| 2014 | ASTM A105/A105M-14 | Revisions related to supplementary requirements and heat treatment notes. |

| 2018 | ASTM A105/A105M-18 | Editorial corrections and standard reapproval. |

| 2021 | ASTM A105/A105M-21 | |

| 2023 | ASTM A105/A105M-23 | |

| 2024 | ASTM A105/A105M-24 | Latest revision: updated references, clarified definitions, and material conditions. |

For the most current specifications and requirements, please refer to the latest edition: ASTM A105/A105M-24, published in April 2024

check and Download latest edition of ASTM A105/A105M-24 , ASME SA105/SA105M Sect II Part A Ed.2023

⬇️ Download ASTM A105/A105M-24 (PDF)

⬇️ Download ASTM A105 specification (PDF)

1. ASTM A105 Scope

1.1 This specification covers forged carbon steel piping components for ambient- and higher-temperature service in pressure systems. Included are flanges, fittings, valves, and similar parts

2. Forgings made to this specification are limited to a maximum weight of 10 000 lb [4540 kg]. Larger forgings may be ordered to Specification A266/A266M.

2. Referenced Documents of ASTM A105

In addition to those reference documents listed in Specification A961/A961M, the following list of standards apply to this specification:

- A266/A266M Specification for Carbon Steel Forgings for Pressure Vessel Components

- A675/A675M Specification for Steel Bars, Carbon, Hot-Wrought, Special Quality, Mechanical Properties

- A696 Specification for Steel Bars, Carbon, Hot-Wrought or Cold-Finished, Special Quality, for Pressure Piping Components

- A788/A788M Specification for Steel Forgings, General Requirements

- A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

- MSS SP 44 Standard for Steel Pipe Line Flanges⁴

- ASME B16.5 Dimensional Standards for Steel Pipe Flanges and Flanged Fittings⁵

- ASME B16.9 Wrought Steel Buttwelding Fittings⁵

- ASME B16.10 Face-to-Face and End-to-End Dimensions of Ferrous Valves⁵

- ASME B16.11 Forged Steel Fittings, Socket Weld, and Threaded⁵

- ASME B16.34 Valves-Flanged, Threaded and Welding End⁵

- ASME B16.47 Large Diameter Steel Flanges⁵

- API-600 Flanged and Butt-Welding-End Steel Gate Valves⁶

- API-602 Compact Design Carbon Steel Gate Valves for Refinery Use⁶

3. ASTM A105 Forgings General Requirements

Product furnished to this specification shall conform to the requirements of Specification A961/A961M, including any supplementary requirements that are indicated in the purchase order. Failure to comply with the requirements of Specification A961/A961M constitutes nonconformance with this specification. In case of a conflict between the requirements of this specification and Specification A961/A961M, this specification shall prevail.

4. ASTM A105 Heat Treatment Requirement

A105N means the material has been normalized for better low-temperature performance.

Forgings above Class 300 or >4” NPS must be normalized, normalized & tempered, or quenched & tempered.

Heat treatment, when required shall be annealing, normalizing, or normalizing and tempering or quenching and tempering in accordance with Specification A961/A961M

5. Chemical Composition

The ASTM A105 steel shall conform to the chemical requirements specified in below table

For each reduction of 0.01 % below the specified carbon maximum (0.35 %), an increase of 0.06 % manganese above the specified maximum (1.05 %) will be permitted up to a maximum of 1.65 %.

| Element | Composition, % |

| Carbon | 0.35 max |

| Manganese | 0.60–1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10–0.35 |

| Copper | 0.40 maxᴬ |

| Nickel | 0.40 maxᴬ |

| Chromium | 0.30 maxᴬ,ᴮ |

| Molybdenum | 0.12 maxᴬ,ᴮ |

| Vanadium | 0.08 maxᴬ |

| ᴬThe sum of copper, nickel, chromium, molybdenum and vanadium shall not exceed 1.00 %. | |

| ᴮThe sum of chromium and molybdenum shall not exceed 0.32 %. |

6. Mechanical Properties and Hardness requirement for A105 Steel

The material shall conform to the mechanical property requirements prescribed in Below Table

| Mechanical Property | Value |

|---|---|

| Tensile strength (minimum) | 70 ksi [485 MPa] |

| Yield strength (minimum) | 36 ksi [250 MPa] |

| Elongation in 2 in. or 50 mm (minimum) – Standard round or proportionally sized specimen | 22% |

| Elongation in 2 in. or 50 mm (minimum) – Strip specimens (wall thickness ≥ ⅛ in. [7.94 mm] and small sizes tested in full section) | 30% |

| Formula for calculating minimum elongation for strip specimens thinner than ⅛ in. [7.94 mm] (inch – pound units) | 48t + 15 (t = actual thickness in inches) |

| Formula for calculating minimum elongation for strip specimens thinner than ⅛ in. [7.94 mm] (SI units) | 1.9t + 15 (t = actual thickness in mm) |

| Reduction of area (minimum) – Round specimens only | 30% |

| Hardness (maximum) | 197 HBW |

Hardness Tests:

Two hardness tests shall be made for each heat of as-forged components. When more than one forging is produced with each heat, a minimum of two forgings shall be tested with one reading from each forging. When only one forging is produced, it shall be tested in two locations.

7. Hydrostatic Tests

Such tests shall be conducted by the forging manufacturer only when Supplementary Requirement S57 in Specification A961/A961M is specified.

8. Surface Finish, Appearance, and Corrosion Protection

11.1 The requirements of Specification A961/A961M apply to forgings and finished parts.

9.Certification and Marking

Certification type: EN 10204 3.1

Material must be marked per ASTM A105 with:

Manufacturer ID

Heat number

A105 (or A105N)

Size and rating

Specification reference

Typical Flange type of ASTM A105 Flanges

- ASTM A105 Weld neck flanges (WN)

- ASTM A105 Slip-on flanges (SO)

- ASTM A105 Blind flanges (BL)

- Threaded flanges (TH)

- Socket weld flanges (SW)

- Lap joint flanges (LJ)

ASTM A105 Flanges Dimensions & Tolerances

- Dimensions are typically as per ASME B16.5, covering:

- Pressure classes: 150, 300, 600, 900, 1500, and 2500

- Nominal Pipe Sizes (NPS): ½” to 24”

- Tolerances per ASME B16.5 and/or customer drawing.

ASTM A105 and ASTM A105M Difference

ASTM A105 and ASTM A105M are standards of the American Society for Testing and Materials (ASTM) for carbon steel forgings used in pipe components. The main difference between them lies in:

- ASTM A105: It uses the imperial unit system. The numerical expressions for material dimensions, performance indicators, etc. follow the imperial system. For example, the length unit may be inches.

- ASTM A105M: It uses the metric unit system. The relevant dimensions, performance, etc. are expressed in the International System of Units (metric system). For instance, the length unit is millimeters and the unit of force is Newton.

ASTM A105 and SA105

ASTM A105 and SA105 are the same material.and according to ASME SA105,it is Identical with ASTM Specification A 105/A 105M

However,SA105 is suitable for pressure vessel code use.

They are chemically and mechanically identical, but SA105 carries stricter documentation and certification requirements.

ASTM A105 and ASTM A105N

ASTM A105N is the A105 forging material with Normalization heat treatment

ASTM A105N with Normalization heat treatment improves:

- Grain structure

- Toughness

- Uniformity

- Low-temperature impact resistance

That’s why A105N is often used in critical services like:

- Sour gas environments (NACE MR0175)

- Pressure vessels

- Cryogenic services

Low Temperature Service

- Standard ASTM A105 is not impact-tested by default.

- But we can supply ASTM A350 LF2 / ASTM A105 Dual grade for For applications below –46°C,

About ASTM A105 (FAQ)

All answers you want to know about ASTM A105.

1. What is ASTM A105?

ASTM A105 is a specification developed by ASTM International that covers carbon steel forgings for piping components, including flanges, fittings, valves, and parts for high-temperature and high-pressure systems. It is commonly used in oil & gas, petrochemical, and power industries.

2. What are the mechanical properties of ASTM A105?

Typical minimum mechanical properties Of ASTM A105

| Property | Value |

|---|---|

| Tensile Strength | ≥ 485 MPa (70 ksi) |

| Yield Strength | ≥ 250 MPa (36 ksi) |

| Elongation | ≥ 22% |

| Hardness | ≤ 187 HBW (Standard) |

Note: Properties may vary slightly depending on forging and heat treatment.

3. Is ASTM A105 suitable for low-temperature service

By default, ASTM A105 is not intended for low-temperature service. However, it can be normalized or Charpy tested to meet certain low-temperature requirements. For dedicated low-temperature applications, We can provide ASTM A350 LF2 ASTM A105 Dual grade materials.

4. What are the common applications of ASTM A105?

- Forged flanges (weld neck, slip-on, blind, socket weld)

- Pipe fittings and forged valves

- Components in pressure vessels, boilers, and heat exchangers

- Used in oil refineries, chemical plants, power stations

5. Does ASTM A105 require heat treatment

Forgings above Class 300 or >4” NPS must be normalized, normalized & tempered, or quenched & tempered.

6. What is the difference between ASTM A105 and A105N?

- A105 refers to the material in general.

- A105N means the material has been normalized (heat treated at ~900°C and air-cooled).

- Normalizing improves grain structure, toughness, and consistency, making A105N suitable for critical applications.

7. Is ASTM A105 weldable?

Yes, ASTM A105 has good weldability using conventional welding methods such as SMAW, GTAW, or MIG, provided proper preheating and post-weld heat treatment (PWHT) is followed for thicker sections.Normally A105 material match ASTM A234 Fittings,A106 grade B Pipes in the pipeline connection

8.What standards and certifications apply to ASTM A105 flanges?

- ASME B16.5, ASME B16.47 – Flange dimensions

- ASME B31.1 / B31.3 – Process piping codes

- EN 10204 3.1 / 3.2 – Material test certificates

- NACE MR0175 – Optional if used in sour service (must control hardness)

9.What is the requirement for ASTM A105 material comply with NACE MR-0175

1. NACE MR 0175 Hardness Requirement for ASTM A105

- Maximum allowable hardness:≤ 187 HBW Brinell)

- This is the most critical requirement.

- Often requires post-forging heat treatment (typically normalizing, or normalize + temper)

2. Microstructure & Heat Treatment

- Heat treatment is mandatory to achieve the required hardness.

- Acceptable treatments:

- Normalized

- Normalized + Tempered

- As-forged (without heat treatment) condition is not acceptable for sour service.

3. Chemical Composition

- The base chemical composition of ASTM A105 typically meets NACE MR0175, but:

- Sulfur (S) should be low to minimize sulfide stress cracking risk.

- Verify composition against project or client-specific restrictions.

4. Documentation & Certification

- The MTC (Mill Test Certificate) should:

- State the actual hardness (not just mechanical properties).

- Include heat treatment details.

- Confirm compliance with NACE MR0175/ISO 15156 as per purchaser requirement.

10, SUMMARY OF CHANGES in ASTM A105 2024 Edition

Committee A01 has identified the location of selected changes to this standard since the last issue (A105/A105M – 23) that may impact the use of this standard. (Approved April 15, 2024.)

(1) Revised Table 2 and deleted Table 3.

(2) Revised 8.3.3 on Tension Tests.

Committee A01 has identified the location of selected changes to this standard since the last issue (A105/A105M – 21) that may impact the use of this standard. (Approved May 1, 2023.)

(1) Revised Table 1 and Table 3.