ASTM A350 LF2 Weld Neck Flanges Manufacturer

We specialize in manufacturing high‑quality forged weld neck flanges made from ASTM A350 LF2 carbon steel — perfect for low-temperature, high-pressure pipeline applications.

We a leading manufacturer and global supplier of ASTM A350 LF2 Weld Neck Flanges, specializing in carbon steel forged flanges for low-temperature service. With a focus on quality, precision, and reliability, our flanges meet or exceed international standards such as ASME B16.5, ASME B16.47, and EN 1092-1.

ASTM A350 LF2 Flanges is welding with ASTM A420 WPL6 Pipe fittings in the pipeline to make the spool

What is ASTM A350 LF2 Weld Neck Flange?

ASTM A350 LF2 is a low-alloy carbon steel material used for forged flanges, fittings, and valves intended for low-temperature applications. A Weld Neck Flange (WN flange) features a long tapered hub and is butt-welded to a pipe, ensuring high structural integrity and excellent stress distribution under high pressure and temperature fluctuations.

ASTM A350 LF2 is a low-alloy, carbon steel forging grade commonly used in pressure piping and vessel applications requiring excellent impact toughness at low temperatures (down to –46°C / –50°F). It’s widely used in oil & gas, petrochemical, cryogenic, and offshore environments.

ASTM A350 is the Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components

ASTM A350 Complete Current Latest Edition:2024 EDITION

Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components – Nov. 1, 2024

Download the ASTM A350 2024B EDITION PDF

LF2 refers to Low temperature Forging grade 2.

ASTM A350 LF2 CL1 and ASTM A350 LF2 CL2 ,they have the some Chemical Composition,but they have the different mechnical properties

ASTM A350 LF2 CL1 and CL2 are two classes of the same material but differ in impact – related properties and forging quality levels:

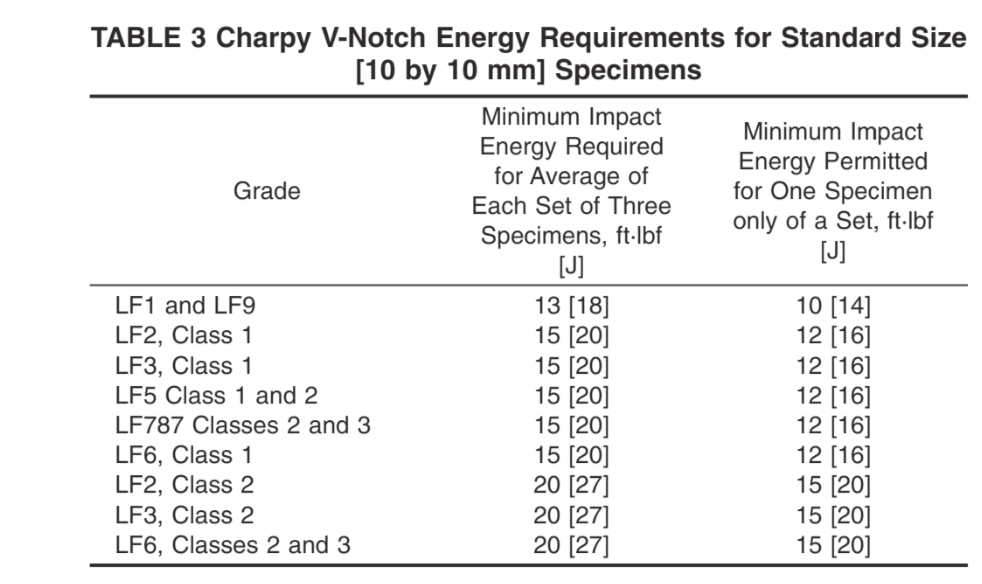

Impact Energy Requirements:

A350 LF2 CL1: The minimum average impact energy for each set of three specimens is 15 ft·lb (20 J), and for one specimen, it is 12 ft·lb (16 J).

A350 LF2 CL2: The minimum average impact energy for each set of three specimens is 20 ft·lb (27 J), and for one specimen, it is 15 ft·lb (20 J). Thus, CL2 has higher impact – energy requirements, indicating better toughness under impact.

Impact Test Temperature:

CL1 has a test temperature of – 50°F (- 46°C).

CL2 has a test temperature of 0°F (- 18°C).

ASTM A350 LF2 Chemical Composition

| Element | Composition, w.t % Grades | ||||||

| LF1 | LF2 | LF3 | LF5 | LF6 | LF9 | LF787 | |

| C | ≤0.30 | ≤0.30 | ≤0.20 | ≤0.30 | ≤0.22 | ≤0.20 | ≤0.07 |

| Mn | 0.60-1.35 | 0.60-1.35 | ≤0.90 | 0.60-1.35 | 1.15–1.50 | 0.40–1.06 | 0.40–0.70 |

| P | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.025 | ≤0.035 | ≤0.025 |

| S | ≤0.040 | ≤0.040 | ≤0.040 | ≤0.040 | ≤0.025 | ≤0.040 | ≤0.025 |

| Si | 0.15-0.30 | 0.15-0.30 | 0.20-0.35 | 0.20-0.35 | 0.15-0.30 | … | ≤0.40 |

| Ni | ≤0.40 | ≤0.40 | 3.30-3.70 | 1.00-2.00 | ≤0.40 | 1.60-2.24 | 0.70–1.00 |

| Cr | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | 0.60–0.90 |

| Mo | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | 0.15-0.25 |

| Cu | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.40 | 0.75–1.25 | 1.00-1.30 |

| Cb | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≥0.02 |

| V | ≤0.08 | ≤0.08 | ≤0.03 | ≤0.03 | 0.04-0.11 | ≤0.03 | ≤0.03 |

| N | … | … | … | … | 0.01–0.030 | … | … |

Mechanical requirements for ASTM A350 LF2

the Mechanical requirements for ASTM A350 LF2 (Classes 1 and 2) at room – temperature tensile testing are as follows:

- Tensile Strength: 70–95 ksi [485–655 MPa].

- Yield Strength (minimum): 36 ksi [250 MPa], determined by either the 0.2 % offset method or the 0.5 % extension under – load method.

- Elongation:

- Standard round specimen (or small proportional specimen): 22 % minimum in 4D gauge length.

- Strip specimen (for wall thickness ⁵⁄₁₆ in. [7.94 mm] and over, and for all small sizes tested in full section): 30 % minimum in 2 in. [50 mm].

- Reduction of Area (minimum): 30 % (for round specimens only).

A350 LF2 Weld Neck Flanges Specification

- Full compliance with ASTM A350 LF2 Class 1/Class 2 specifications

- Manufactured to ASME B16.5 / B16.47 A&B. dimensional standards

- Available in sizes ½” to 60” (DN15 to DN1500)

- Pressure ratings: 150# to 2500#

- Impact tested at –46°C (Charpy V-notch)

- NACE MR0175 / ISO 15156 compliance for sour service

- EN 10204 3.1 / 3.2 certificates available

Other Flange type available:

Slip-On (SO) Blind (BL) Socket Weld (SW)

Lap Joint (LJ) Threaded (TH) Long Weld Neck (LWN) Reducing Flanges

ASTM A350 LF2 WN Flanges – Heat Treatment

ASTM A350 LF2 material must undergo heat treatment to ensure proper toughness at low temperatures, especially at –46°C (–50°F).Required Heat Treatment:

Normalization or Normalization followed by tempering

A typical ITP Inspection and Test Plan for ASTM A350 LF2 Weld neck Flanges

| Stage | Activity | Requirement/Standard | Type of Check | Acceptance Criteria | Inspector | Document Reference |

| 1 | Raw Material Verification | ASTM A350 LF2 | Certificate Review | Chemical & Mechanical per spec | Manufacturer / QC | Mill Certificate (MTC) |

| 2 | Visual Inspection (Raw Material) | Internal Standard | Visual | No defects, cracks, damage | QC | Inspection Report |

| 5 | Forging Process | ASTM A350 | Process Control Check | As per forging procedure | QC | Forging Log |

| 3 | Heat Treatment | As per ASTM A350 / Client Spec | Temperature & Time Log | Normalized / Tempered as required | QC | HT Report |

| 6 | Final Machining | ASME B16.5/B16.47 | Measurement | Tolerances within limits | QC | Dimensional Report |

| 4 | Dimensional Inspection | ASME B16.5 / B16.47 / Drawing | Measurement Tools | As per drawing | QC | Dimensional Report |

| 7 | Mechanical Testing | ASTM A350 | Tensile, Yield, Elongation | Min. Yield 250 MPa, etc. | Lab / QC | Mechanical Test Report |

| 8 | Charpy V-Notch Impact Test | ASTM A350 at –46°C | Destructive Test | Min 27 J avg (3 samples) | Lab / Third Party (if TPI) | Impact Test Report |

| 9 | Non-Destructive Testing (Optional) | Client Requirement | UT / MT / PT | As per ASME / Client standard | NDT Level II / TPI | NDT Reports |

| 10 | Final Visual and Dimensional Check | ASME B16.5 / Drawing | Visual, Measurement | Surface finish, dimensions OK | QC / Client / TPI | Final Inspection Report |

| 11 | Marking & Stamping | ASTM A350 / ASME B16.5 | Visual | Proper heat/lot marking | QC | Marking Record |

| 12 | Documentation Review & Compilation | Project Requirement | Review | All docs present and signed | QA/QC | Dossier / Data Book |

| 13 | Packing & Dispatch Inspection | Client/Project Spec | Visual / Verification | Packing list, labels, protection | QC / Client | Packing List, Dispatch Note |

Looking for a reliable manufacturer of ASTM A350 LF2 weld neck flanges? We specialize in producing high-quality carbon steel flanges designed for low-temperature service, meeting ASTM A350 LF2 specifications NACE MR 0175 compliance.

Does NACE MR-0175/ISO 15156 specifies the Hardness requirement for ASTM A350 Grade LF2 material?

NACE MR0175/ISO 15156 does not dictate the hardness requirements that may be present in other standards. The standard does define material requirements and use limits as they relate to environmental cracking in the presence of H2S. ASTM A350 LF2 requires the hardness to be 197 HB maximum and this meets the requirements for carbon steel forgings in NACE MR0175/ISO 15156-2. Please refer to Clause A.2.1 and the sub-clauses beneath it for carbon and low alloy steels.

Contact us to receive a Sample MTC for ASTM A350 LF2 Weld neck Flanges.

⬇️Download ASTM A350 LF2 specification

⬇️Download ASTM A350 Standard Latest Edition (PDF)

Download the Dimension of ASME B16.5 Weld neck Flange

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 150 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 300 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 400 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 600 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 900 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 1500 lbs ASME B16.5 PDF

⬇️ Download Dimension of ASTM A350 LF2 Weld Neck flanges Class 2500 lbs ASME B16.5 PDF