Flanges can be made according to different standard,such as ASME,DIN,JIS standards.

DIN Flange standard,now known as EN 1092-1 for steel flanges,but previouly,it is DIN standard,like

EN 1092- 1 Standard

The standard EN 1092-1 was first published by CEN (European Committee for Standardization) in the year 2001.It is to replace the old DIN standard for flanges,

EN 1092 – 1 is a European standard titled “Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN designated – Part 1: Steel flanges”.

Scope of Application

It specifies requirements for circular steel flanges with nominal pressures (PN) ranging from PN 2.5 to PN 400 and nominal sizes (DN) from DN 10 to DN 4000. It is applicable in various industrial sectors such as chemical, petrochemical, food, pharmaceutical, oil and gas, power generation, and water treatment industries.

Main Contents

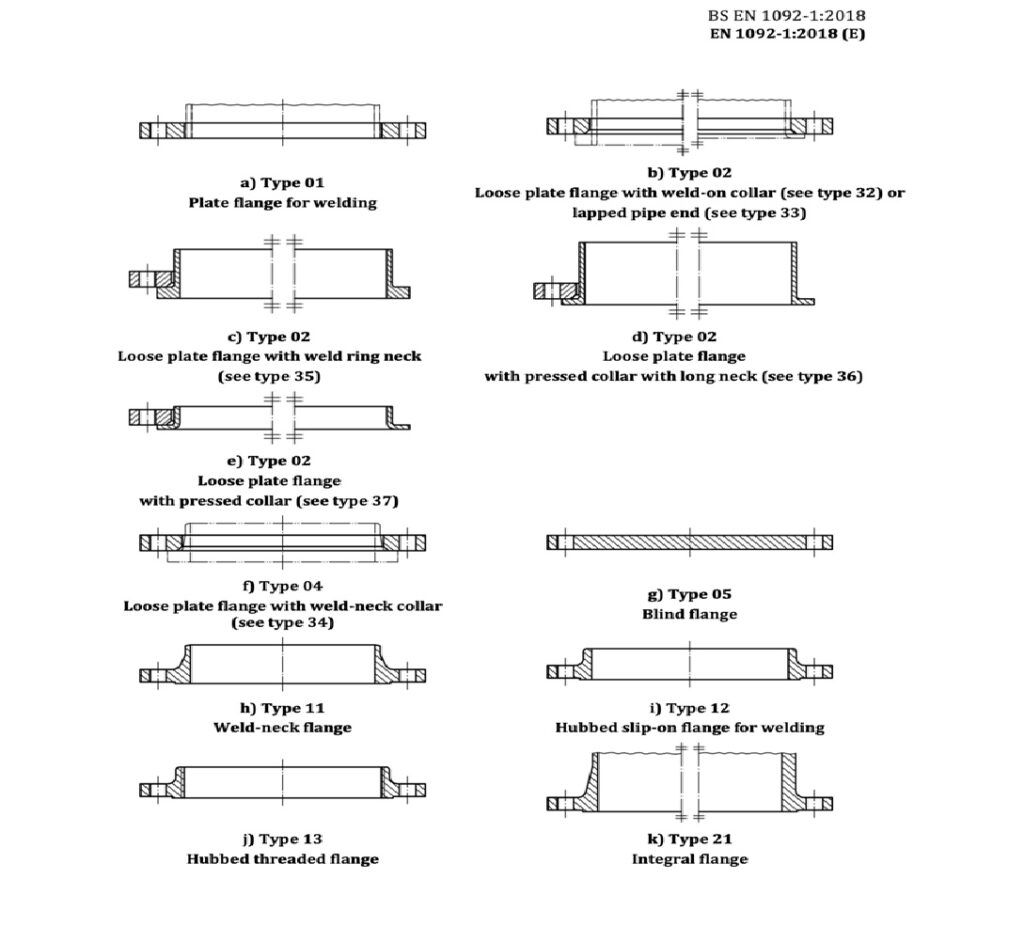

- Flange Types and Seal Faces

- Different types of flanges and their seal face forms are defined. Common types include slip – on flanges (e.g., en 1092 – 1 type 01a, where “type 01” indicates a welded flange and “a” indicates a flat seal face) and loose – flanged flanges (e.g., en 1092 – 1 type 02a, where “type 02” indicates a loose – flanged flange). Different types are suitable for different pressure ratings and temperature conditions, and the seal face form significantly affects the performance of the joint.

- Dimensions and Tolerances

- Dimensions of flanges such as outside diameter, inside diameter, thickness, and bolt hole spacing are specified, along with corresponding tolerance ranges, to ensure that flanges produced by different manufacturers can be mutually compatible

Carbon Steel (Non-alloy)

| Carbon Steel (Non-alloy) | |||

| Material Grade | EN Equivalent | Old DIN | Use |

| P245GH | EN 10222-2 | C22.8 | General use in pressure vessels |

| P250GH | EN 10222-2 | — | Slightly improved over P245GH |

| P265GH | EN 10222-2 | — | Higher temperature/pressure service |

| S235JR / S275JR / S355JR | EN 10025 | St37, St44, St52 | Structural applications (low pressure) |

Stainless Steel grade

| Material Grade | EN Grade | ASTM Equivalent | Use |

|---|---|---|---|

| 1.4301 | X5CrNi18-10 | AISI 304 | General corrosion resistance |

| 1.4307 | X2CrNi18-9 | AISI 304L | Low carbon version, for welding |

| 1.4401 | X5CrNiMo17-12-2 | AISI 316 | Higher corrosion resistance |

| 1.4404 | X2CrNiMo17-12-2 | AISI 316L | Weldable, low carbon |

| 1.4541 | X6CrNiTi18-10 | AISI 321 | With titanium, for high temp stability |

🔹 Alloy Steel

| Material Grade | Material Standard | Use |

|---|---|---|

| 16Mo3 | EN 10028-2 | High-temperature resistance, steam service |

| 13CrMo4-5 | EN 10222-2 | High temp and pressure, especially in boilers |

| 10CrMo9-10 | EN 10222-2 | For petrochemical and thermal plant use |

- Pressure and Temperature Ratings

- It uses the PN (Pressure Nominal) system for pressure classification of flanges. PN represents the maximum working pressure (in bar) that a flange can withstand under normal operating conditions. Different PN ratings correspond to different pressure and temperature – bearing capacities. It should be noted that this PN pressure rating system is unique to Europe and may be different from the pressure rating systems in other regions (such as ANSI/ASME or JIS standards).

- Threads, Bolt Sizes, and Surface Treatment

- Thread specifications and bolt sizes for flange connections, as well as requirements for the surface finish of the flange seal face, are specified to ensure the tightness and reliability of the connection.

- Marking

- Material designation (e.g., P245GH or 1.4301)

- Type number (e.g., Type 11 for weld neck flange)

- Pressure rating (e.g., PN16)

- Nominal size (e.g., DN100)

- Manufacturer’s mark and batch

Now Old DIN standard flanges are still using by many engineers,so it is important to understand the comparison of EN 1092-1 and old DIN standard flanges.Below you would find the mapping table.

EN 1092-1 Flange and DIN standard Mapping Table

| Old DIN Standard | EN 1092-1 Type | Description |

|---|---|---|

| DIN 2501 (Part 1-3) | EN 1092-1 (General) | Base standard for circular flanges |

| DIN 2573 PN6 / DIN 2576 PN10 | EN 1092-1 Type 01 | Plate flange (without hub) |

| DIN 2631 / DIN 2632 / 2633 / 2634 / 2635 | EN 1092-1 Type 11 | Weld neck flange (with hub), various pressure classes |

| DIN 2641 / 2642 | EN 1092-1 Type 02 | Loose plate flange with weld-on collar |

| DIN 2643 / 2644 | EN 1092-1 Type 04 | Loose plate flange with threaded collar |

| DIN 2655 / 2656 | EN 1092-1 Type 05 | Loose flange with lapped collar |

| DIN 2627 / 2628 / 2629 | EN 1092-1 Type 13 | Welding neck collar |

| DIN 2565 / 2566 | EN 1092-1 Type 14 | Threaded flange |

| DIN 2527 | EN 1092-1 Type 05 | Blind flange |

| DIN 2673 | EN 1092-1Type 21 | Integral flange (machined from pipe or forging) |

Other EN 1092 Series standard

| Part | Standard | Material Type |

|---|---|---|

| Part 1 | EN 1092-1 | Steel flanges |

| Part 2 | EN 1092-2 | Cast iron flanges |

| Part 3 | EN 1092-3 | Copper alloy flanges |

| Part 4 | EN 1092-4 | Aluminium alloy flanges |

EN 1092-1 Flange type